Introduction

In the competitive landscape of e-commerce, efficient and accurate order fulfillment is paramount to success. E-commerce shippers often grapple with escalating order volumes, leading to delays in delivery times and diminished customer satisfaction. Geek+ warehouse automation software addresses these challenges by leveraging automation and artificial intelligence (AI) to optimize warehouse operations.

The Benefits of Automating Your Warehouse with Geek+ Software

Implementing Geek+ warehouse automation software offers a myriad of advantages over traditional manual warehouse operations. Automation of tasks such as receiving, putaway, picking, and shipping not only reduces the reliance on human labor but also enhances order fulfillment speed and accuracy. According to a McKinsey report, automation can reduce labor costs by up to 20% and improve order accuracy by 30%.

- Increased Efficiency: Automated systems streamline operations, allowing for faster processing of orders.

- Cost Reduction: Minimizing human labor leads to significant savings in operational costs.

- Enhanced Accuracy: Advanced algorithms reduce the likelihood of errors in order fulfillment.

- Optimized Inventory Management: Machine learning algorithms optimize inventory placement and picking paths.

Moreover, Geek+ software provides real-time visibility into warehouse operations, enabling managers to monitor inventory levels, track order progress, and identify areas for improvement. Detailed performance reports empower data-driven decision-making and strategic planning, ultimately streamlining warehouse operations for maximum efficiency and profitability.

How Geek+ Software Can Help E-Commerce Shippers Streamline Their Operations

E-commerce shippers encounter several unique challenges, including fluctuating order volumes and the necessity for rapid order processing. Geek+ software tackles these issues by offering robust real-time inventory management, facilitating the swift location and fulfillment of orders. The software seamlessly integrates with existing warehouse management systems (WMS), ensuring a smooth incorporation of automation into current operations.

Real-Time Inventory Management

With real-time inventory management, Geek+ software allows shippers to maintain accurate inventory levels, thereby improving order accuracy and reducing stockouts. This functionality is supported by Gartner's 2023 report, which indicates that real-time inventory tracking can enhance operational efficiency by 25%.

Integration with Warehouse Management Systems

Ease of integration with existing WMS platforms ensures that E-commerce shippers can adopt Geek+ software without overhauling their current systems. This compatibility allows for synchronized operations, reducing downtime and ensuring continuity in warehouse processes.

Advanced Analytics and Machine Learning

Geek+ software incorporates advanced analytics and machine learning to provide actionable insights into warehouse operations. By identifying bottlenecks and optimizing inventory levels, shippers can make informed, data-driven decisions to enhance overall efficiency and customer satisfaction.

Demand Prediction and Inventory Optimization

The software's machine learning algorithms predict demand trends, allowing for optimal inventory management. This predictive capability helps in avoiding stockouts and overstocking, thereby reducing lost sales and unnecessary inventory costs. Studies from ScienceDirect emphasize that predictive analytics can increase forecasting accuracy by up to 35%.

Understanding the Key Features of Geek+ Warehouse Automation Software

Geek+ warehouse automation software encompasses a comprehensive suite of features designed to maximize warehouse efficiency. These features include:

- Automated Storage and Retrieval Systems (AS/RS): Streamlines the storage and retrieval of goods, reducing handling time and minimizing errors.

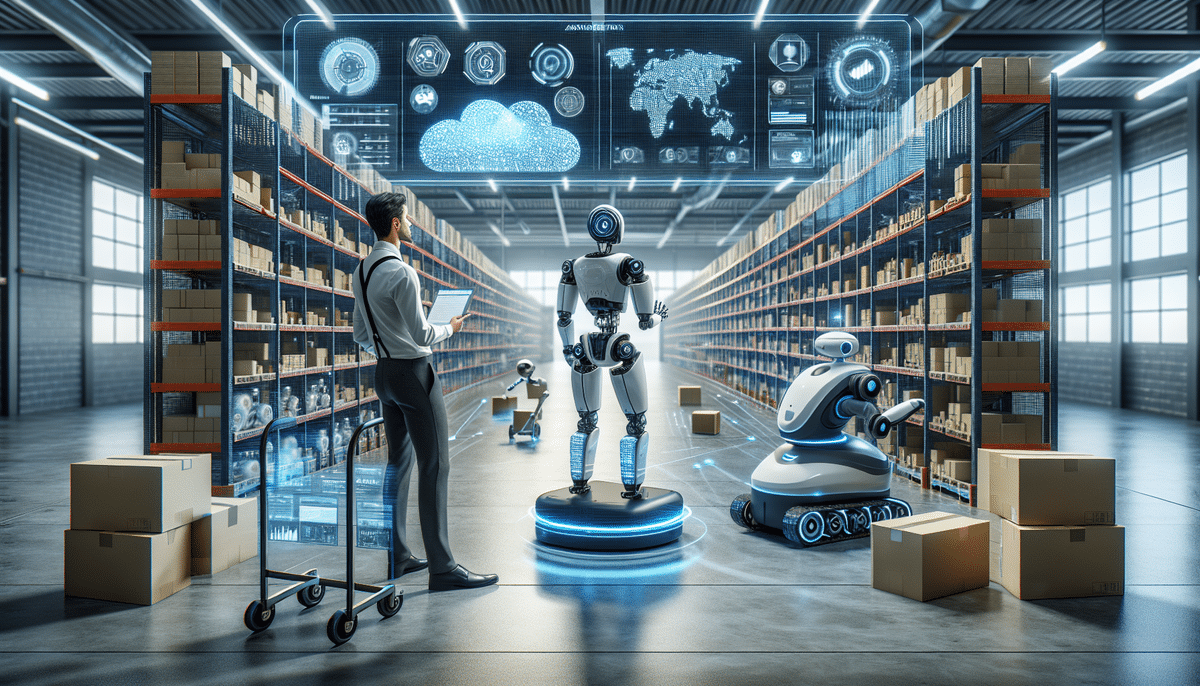

- Robotic Order Picking and Packing: Utilizes robotics to accurately pick and pack orders, increasing speed and reducing human error.

- Autonomous Delivery Robots: Facilitates the autonomous movement of goods within the warehouse, enhancing workflow and reducing delays.

- Central Control System: Provides real-time monitoring and control of all automated processes, ensuring seamless operations.

- Data Analytics Capabilities: Collects and analyzes data from various sources, offering insights for inventory management and process optimization.

- Flexibility and Scalability: Customizable to meet the specific needs of different warehouses, and scalable to accommodate growth or changes in operations.

The integration of these features ensures that warehouse operations are not only efficient but also adaptable to the evolving demands of the e-commerce industry.

The Role of Artificial Intelligence in Geek+ Automation Software

Artificial intelligence (AI) is integral to the functionality of Geek+ warehouse automation software. By analyzing data related to order volumes, inventory levels, and picking patterns, the software's algorithms optimize warehouse operations in real-time. The incorporation of machine learning enables the software to continuously learn and adapt to changing warehouse conditions, enhancing operational efficiency over time.

Error Reduction in Order Picking

AI-driven optimization allows the software to determine the most efficient picking routes, providing real-time guidance to warehouse workers. This reduces the likelihood of errors and enhances overall productivity. A study by IBM Research found that AI integration in warehouse operations can decrease picking errors by up to 40%.

Predictive Maintenance

AI facilitates predictive maintenance by analyzing data on equipment usage and performance. This proactive approach enables the identification of potential issues before they escalate into significant problems, thereby minimizing downtime and maintenance costs. According to Forbes, predictive maintenance can reduce maintenance costs by 12%, increase equipment uptime by 15%, and extend machinery lifespan.

A Comprehensive Guide to Implementing Geek+ Warehouse Automation Software

Planning and Preparation

The implementation of Geek+ warehouse automation software begins with meticulous planning and preparation. This phase involves assessing the current warehouse operations, identifying key areas for improvement, and customizing the software to align with the specific needs of the warehouse.

Customization and Installation

Geek+ offers tailored solutions to ensure seamless integration with existing systems. Their team of engineers and project managers collaborates closely with each customer to customize the software and oversee the installation process, ensuring minimal disruption to ongoing operations.

Ongoing Support and Maintenance

Post-installation, Geek+ provides comprehensive support and maintenance services. This ensures that the software remains operational and up-to-date, addressing any issues promptly to maintain optimal performance.

Technical Requirements

Successful implementation of Geek+ automation software necessitates meeting certain technical requirements. These include a stable network connection, adequate ceiling height, and sufficient space for the automated systems. Additionally, a stable power supply is essential to support the operational demands of the automated equipment.

Case Studies: Real-Life Examples of Companies Using Geek+ Software Successfully

Geek+ warehouse automation software has been adopted by numerous companies across diverse industries, yielding substantial improvements in operational efficiency and cost efficiency. Below are examples of successful implementations:

Automotive Industry Success

A leading automotive manufacturer faced challenges in managing its extensive inventory of spare parts, leading to delays in order processing and heightened labor costs. Upon deploying Geek+ software, the company automated its warehouse operations, achieving a 30% reduction in labor costs and a 50% decrease in order processing times.

Retail Industry Success

A major retail chain struggled to meet the growing demand for online orders, resulting in delayed deliveries and reduced customer satisfaction. The implementation of Geek+ software streamlined their order processing and fulfillment operations, leading to a 40% reduction in order processing times and a marked improvement in customer satisfaction.

These case studies demonstrate Geek+'s ability to deliver measurable improvements in efficiency and customer service across various sectors.

Comparing Geek+ Warehouse Automation Software to Other Solutions in the Market

When evaluating warehouse automation solutions, Geek+ stands out due to its advanced technology, customization options, and integration capabilities. Compared to traditional manual operations and other automation solutions, Geek+ offers several distinct advantages:

Advanced Algorithms and AI Capabilities

Geek+'s sophisticated algorithms and AI integration enable real-time optimization of warehouse operations, enhancing speed and accuracy in order fulfillment. This level of intelligence surpasses many existing solutions that rely solely on pre-programmed routines.

User-Friendly Interface

The software's intuitive interface simplifies navigation and operation, allowing warehouse staff to quickly adapt with minimal training. This user-centric design reduces the risk of operational errors and accelerates the adoption process.

Seamless Integration with Existing Systems

Geek+ software is designed to integrate seamlessly with a variety of warehouse management systems and other technologies, facilitating smooth communication and coordination across different operational facets. This interoperability ensures that Geek+ can complement and enhance existing workflows rather than disrupt them.

Overall, Geek+ provides a comprehensive, flexible, and intelligent solution that addresses the multifaceted needs of modern warehouses more effectively than many other options on the market.

Understanding the Technical Requirements for Implementing Geek+ Automation Software

Network and Infrastructure

A stable network connection is vital for the seamless operation of Geek+ automation software. High-speed internet ensures uninterrupted data transmission and real-time monitoring of warehouse processes.

Space and Physical Layout

Implementing automated systems requires adequate physical space, including minimum ceiling heights to accommodate robotic equipment and sufficient floor area for autonomous delivery robots. Proper space planning is essential to facilitate optimal workflow and system performance.

Power Supply

A reliable and sufficient power supply is crucial to support the automated systems. This includes ensuring that the electrical infrastructure can handle the additional load and that backup power solutions are in place to prevent downtime in case of outages.

Compliance and Safety Considerations

Warehouses operating in regulated industries, such as pharmaceuticals or food and beverage, must ensure that Geek+ automation systems comply with relevant industry standards and safety regulations. This may involve additional technical configurations and safeguards to maintain compliance and ensure safe operations.

The Future of Warehouse Automation: Insights from the Creators of Geek+ Software

Geek+ is dedicated to ongoing innovation and development in the realm of warehouse automation. The company is exploring emerging technologies such as augmented reality (AR) and unmanned aerial vehicles (UAVs) to further enhance warehouse efficiency and adaptability. With a commitment to continuous improvement, Geek+ is poised to lead advancements in the future of warehouse automation.

Advancements in Artificial Intelligence and Machine Learning

Geek+ focuses on refining artificial intelligence and machine learning algorithms to further optimize warehouse operations. By analyzing comprehensive data sets related to inventory, order patterns, and operational workflows, these advancements facilitate more informed resource allocation and process optimization.

Integration of Emerging Technologies

Exploring technologies like augmented reality can revolutionize warehouse training and operational procedures, while unmanned aerial vehicles can introduce new efficiencies in inventory management and goods transportation within warehouses. These innovations represent Geek+'s vision for the next generation of warehouse automation solutions.