Introduction to Automated Warehouse Systems

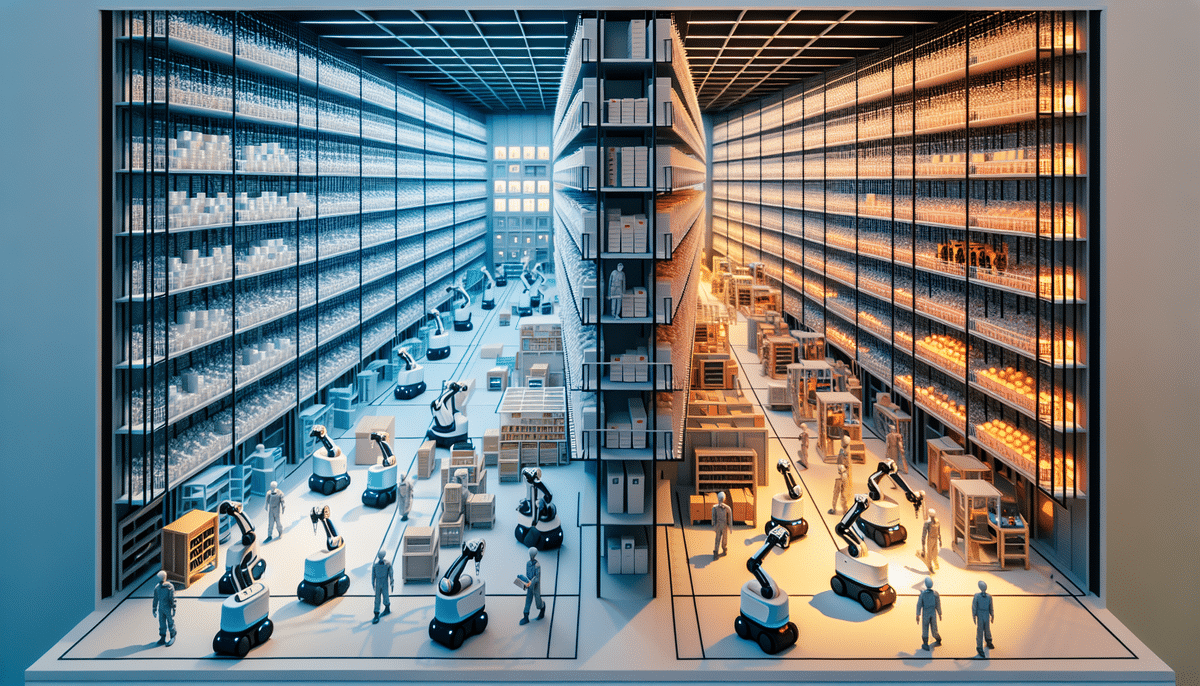

The rapid rise of e-commerce has significantly increased the demand for fast and accurate order fulfillment. Automated warehouse systems are engineered to meet this demand by automating repetitive tasks such as picking, packing, and sorting. Leveraging robots and advanced software, these systems enhance accuracy, boost throughput, and reduce errors, making them a preferred solution for warehouses across various industries. According to a report by Investopedia, the global warehouse automation market is projected to reach $30 billion by 2025.

One of the primary benefits of automated warehouse systems is their ability to optimize space utilization. Utilizing vertical storage systems and automated retrieval technologies, these systems can store and retrieve products efficiently, minimizing the need for expansive warehouse spaces. This not only reduces real estate costs but also accelerates order fulfillment processes, as products can be located and retrieved swiftly.

AutoStore Technology: Enhancing Warehouse Efficiency

AutoStore is an automated warehouse system that employs a grid of storage bins and robotic shuttles to pick and deliver items to workers. Designed to maximize storage density, AutoStore stacks bins vertically and uses robots to retrieve them efficiently. The system is renowned for its modular design, allowing businesses to scale their operations up or down seamlessly based on demand.

One of the key advantages of AutoStore technology is its ability to significantly improve operational efficiency and accuracy. By utilizing robots, the system can swiftly and accurately retrieve items, reducing reliance on manual labor and minimizing the risk of errors. This leads to faster order fulfillment and enhanced customer satisfaction.

Additionally, AutoStore offers exceptional flexibility in terms of layout and configuration. The system can be tailored to fit the specific needs of a business, whether it's a small operation or a large-scale distribution center. Its modular design facilitates easy expansion or reconfiguration as business requirements evolve.

For more detailed insights, refer to Forbes' analysis on automated warehouses.

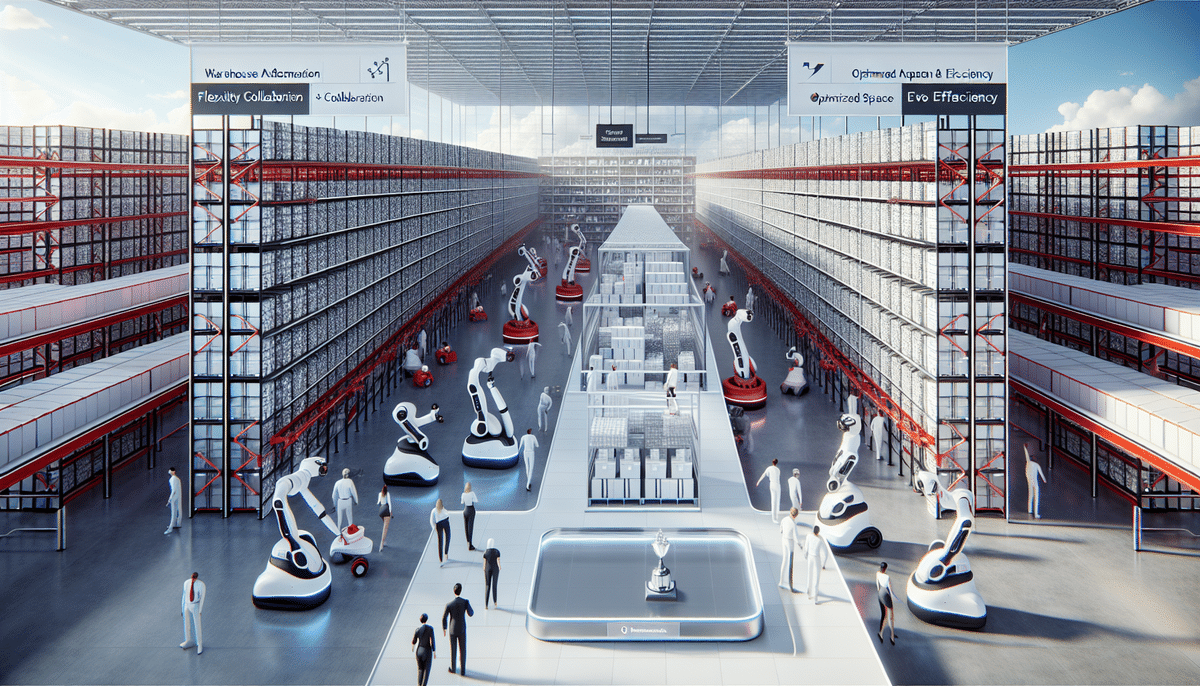

Locus Robotics: Collaborative Automation in Warehousing

Locus Robotics offers an automated picking system designed to collaborate with human workers rather than replace them. The system utilizes collaborative robots, or "cobots," to assist employees in order picking and sorting. Known for its adaptability, Locus Robotics can be integrated into warehouses of all sizes and configurations.

A primary benefit of Locus Robotics is its capacity to enhance productivity and efficiency within warehouse operations. By working alongside human employees, cobots help reduce the time and effort required for order picking and sorting, leading to quicker turnaround times and increased output. Moreover, the system is user-friendly and can be easily integrated with existing warehouse management systems, making it an attractive option for businesses seeking to streamline their operations.

Further information can be found in the McKinsey report on automation in warehousing.

Comparing AutoStore and Locus Robotics: Key Differences

While both AutoStore and Locus Robotics aim to enhance warehouse efficiency, they have distinct differences:

- Design Focus: AutoStore is designed to maximize warehouse space and storage density through a grid and robotic shuttle system. In contrast, Locus Robotics focuses on collaborative automation, working alongside human workers to assist in picking and sorting tasks.

- Scalability: AutoStore offers high scalability, making it suitable for businesses anticipating significant growth. Locus Robotics is scalable as well but may be more fitting for businesses with steady growth patterns.

- Implementation Time: AutoStore typically requires a longer implementation period due to its complexity, whereas Locus Robotics can be operational within weeks.

- Cost: AutoStore demands a higher upfront investment, suitable for larger enterprises, whereas Locus Robotics is more affordable for businesses with smaller budgets.

- Customization: AutoStore provides extensive customization options to tailor the system to specific business needs. Locus Robotics offers a more standardized approach with fewer customization possibilities.

These distinctions are crucial when determining which system aligns best with your business objectives and operational requirements.

Case Studies: Successful Implementations of AutoStore and Locus Robotics

Several organizations across various industries have successfully implemented AutoStore and Locus Robotics systems:

- Farfetch: The luxury fashion brand deployed an AutoStore system in their UK warehouse to enhance order fulfillment capabilities.

- DHL Supply Chain: Implemented Locus Robotics in a North American warehouse, resulting in increased efficiency and accuracy.

- Zalando: Online retailer Zalando introduced an AutoStore system in their German warehouse, boosting storage capacity and reducing order processing times.

- Geodis: Logistics company Geodis integrated Locus Robotics in their French warehouse, improving order accuracy and reducing labor costs.

Beyond operational improvements, these implementations have positively impacted employee satisfaction and safety by allowing staff to focus on more complex tasks while automation handles repetitive and physically demanding work.

For more detailed case studies, visit Robotics Business Review.

Potential Challenges of Implementing Automated Warehouse Systems

Despite the numerous benefits, implementing automated warehouse systems presents several challenges:

- Upfront Investment: The initial cost of acquiring and setting up systems like AutoStore or Locus Robotics can be substantial, posing a financial barrier for some businesses.

- Workflow Integration: Businesses must meticulously plan their workflows and train employees to effectively use the new systems to fully realize the benefits.

- Maintenance and Updates: Automated systems require regular maintenance and software updates to function optimally. Any technical malfunctions can disrupt warehouse operations, necessitating a dedicated maintenance team.

- Product Compatibility: Certain products, especially fragile or irregularly shaped items, may not be suitable for automated systems and may still require manual handling.

Addressing these challenges is essential for a successful transition to automated warehouse operations.

For strategies to overcome these challenges, refer to Supply Chain Digital's guide on warehouse automation challenges.

The Future of Automated Warehouse Systems: Trends and Predictions

The future of automated warehouse systems is promising, with continuous advancements expected to drive the industry forward. Key trends and predictions include:

- Integration of AI and Machine Learning: Enhanced decision-making capabilities and predictive maintenance are expected as AI and machine learning technologies become more integrated into warehouse systems.

- Increased Use of Collaborative Robots: The adoption of cobots will grow, facilitating more seamless collaboration between humans and machines.

- Expansion of IoT Applications: The Internet of Things (IoT) will play a pivotal role in connecting various components of warehouse systems, enabling real-time data exchange and improved analytics.

- Focus on Sustainability: Automated systems will increasingly incorporate sustainable practices, such as energy-efficient operations and the use of renewable energy sources.

These trends indicate a shift towards more intelligent, efficient, and sustainable warehouse operations.

For more insights on future trends, visit the Gartner report on automation trends.

Choosing Between AutoStore and Locus Robotics: Key Considerations

When deciding between AutoStore and Locus Robotics, consider the following factors to determine the best fit for your business:

- Business Needs: Assess whether your operations require high storage density and scalability (favoring AutoStore) or if a collaborative approach with human workers is more suitable (favoring Locus Robotics).

- Budget Constraints: Evaluate your financial capacity for upfront investments. AutoStore may require a larger budget compared to the more affordable Locus Robotics.

- Warehouse Layout: Consider the size and configuration of your warehouse. AutoStore may necessitate more space for its grid system, while Locus Robotics offers greater flexibility in various layouts.

- Customization Needs: Determine the level of customization your operations demand. AutoStore provides extensive customization options, whereas Locus Robotics offers a more standardized solution.

- Implementation Timeline: If a swift implementation is critical, Locus Robotics may be preferable due to its shorter setup time.

- Future Growth Plans: Consider your long-term growth projections. AutoStore's high scalability might better support businesses anticipating significant expansion.

Thoroughly evaluating these factors will guide you in selecting the most appropriate automated warehouse system for your business.

Conclusion: Weighing the Pros and Cons of AutoStore vs. Locus Robotics

In summary, both AutoStore and Locus Robotics offer innovative automated warehouse solutions that can substantially enhance efficiency and accuracy. AutoStore is ideal for businesses with complex order fulfillment requirements and larger budgets, offering high storage density and scalability. On the other hand, Locus Robotics provides a flexible and collaborative approach, making it suitable for businesses with smaller budgets and simpler workflows.

The optimal choice between the two systems hinges on your company's specific needs, budget, warehouse layout, and future growth plans. By carefully considering these factors and understanding the unique offerings of each system, businesses can make informed decisions that align with their operational goals and drive success in the competitive warehousing landscape.

For a deeper comparison and expert opinions, visit Supply Chain Dive's comparison article.