Understanding the Importance of UDS in Package Scales

In the dynamic realm of packaging and logistics, precise weight measurements are paramount. Accurate package weights directly influence shipping costs, inventory management, and customer satisfaction. Ultrasonic Distance Sensor (UDS) systems have emerged as a reliable solution, offering enhanced accuracy and efficiency in weight determination. Unlike traditional manual scales, UDS systems minimize human error by automatically detecting package dimensions and calculating weight in real-time.

According to a U.S. Department of Transportation report, automation in weight measurement can reduce errors by up to 30%, highlighting the critical role of technologies like UDS in modern logistics.

Setting Up UDS for Package Scales

Choosing the Right Location

Proper installation of a UDS system begins with selecting an optimal location within the packaging facility. The area should be free from obstructions, excessive vibrations, and noise to ensure accurate sensor readings.

System Compatibility and Calibration

Ensure that the UDS system is compatible with your existing package scales. Calibration is essential and involves inputting accurate package dimensions and weight capacities. Adhering to the manufacturer's calibration instructions is crucial for maintaining measurement accuracy.

Maintenance and Upkeep

Regular maintenance, including cleaning sensors and inspecting cables, helps prevent malfunctions. Establishing a backup system is also recommended to mitigate potential downtime and technical issues.

Optimizing UDS for Accurate Weight Measurements

Minimizing Environmental Interference

Environmental factors such as temperature fluctuations and vibrations can affect UDS accuracy. Implementing measures to shield the system from these variables is vital for reliable performance.

Investing in Advanced Technologies

Opt for UDS systems equipped with features like noise reduction and temperature compensation. These technologies enhance measurement precision and reduce errors significantly.

Proper Usage Practices

Ensure correct placement of packages on the scale and avoid disturbances during the weighing process. Using the system in controlled environments with minimal foot traffic further optimizes accuracy.

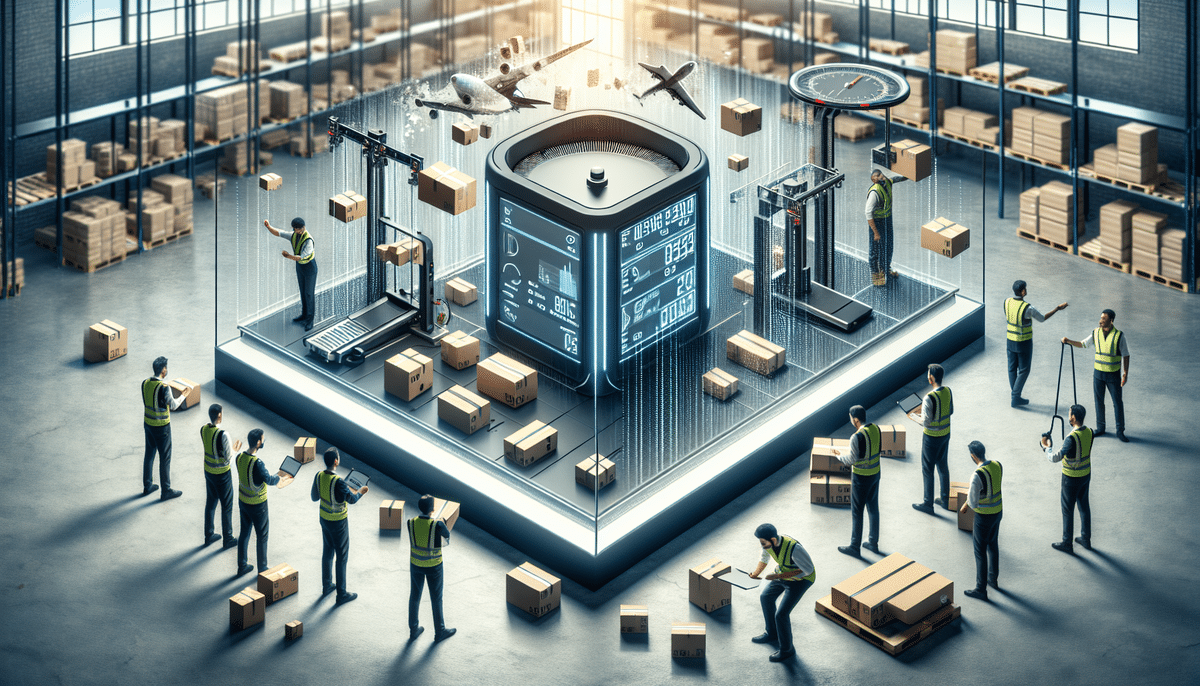

The Benefits of Using UDS in the Packaging Industry

Enhanced Accuracy and Efficiency

UDS systems provide highly accurate weight measurements, reducing financial losses caused by shipping inaccuracies. Automation streamlines the packaging process, saving time and labor costs.

Integration with Other Systems

UDS can seamlessly integrate with barcode scanners, label printers, and inventory management systems, creating a cohesive and efficient workflow. This integration minimizes errors and boosts overall productivity.

Customization and Versatility

UDS systems can be tailored to handle various package sizes, weights, and materials, making them adaptable to diverse packaging needs.

Challenges and Solutions in Managing UDS Systems

Calibration and Maintenance Issues

Regular calibration is necessary to maintain accuracy. Implementing a systematic maintenance schedule can mitigate calibration drift and extend system lifespan.

Technical Complexity and Training

UDS systems may require specialized knowledge for operation and troubleshooting. Providing comprehensive training for staff ensures effective system utilization and reduces the risk of errors.

Cost Considerations

Initial installation and ongoing maintenance costs can be significant. Conducting a cost-benefit analysis helps determine the long-term savings and efficiency gains from UDS implementation.

Selecting the Right UDS System for Your Needs

Key Features to Consider

When choosing a UDS system, consider compatibility with existing scales, accuracy levels, ease of installation, and maintenance requirements. Advanced features like noise reduction and temperature compensation enhance performance.

Connectivity and Integration

Ensure the UDS system supports robust connectivity options for seamless integration with your facility’s network infrastructure. This facilitates efficient data transfer and real-time monitoring.

Durability and Environmental Resistance

Select systems with durable construction and protective features such as shock absorbers or waterproofing, especially if used in harsh environments like warehouses or shipping docks.

Future Trends in UDS Technology and Its Impact on Package Scales

The evolution of UDS technology is set to revolutionize package management further. Future advancements may include enhanced sensor accuracy, machine learning algorithms for predictive maintenance, and greater integration with Internet of Things (IoT) devices. These developments promise increased efficiency, reduced operational costs, and improved scalability for packaging facilities.

According to a McKinsey & Company report, the integration of advanced sensing technologies is expected to drive significant productivity gains in the logistics sector over the next decade.

Best Practices for Managing UDS Systems to Ensure Consistency

Regular Maintenance and Calibration

Implement a routine maintenance and calibration schedule to sustain system accuracy and reliability. Keeping sensors clean and ensuring proper calibration prevents measurement discrepancies.

Training and Standard Operating Procedures

Equip staff with the necessary training to operate and troubleshoot UDS systems effectively. Developing clear standard operating procedures (SOPs) aids in consistent system usage and problem resolution.

Monitoring and Record-Keeping

Maintain detailed records of weight measurements, calibration activities, and maintenance tasks. Analyzing these records helps identify trends, predict potential issues, and make informed decisions for system improvements.

Troubleshooting Common Issues with UDS on Package Scales

Inaccurate Weight Measurements

Ensure the scale is on a level surface and that the load cell is free from debris. Avoid overloading the scale and ensure even weight distribution across the platform.

Calibration Problems

Follow the manufacturer's calibration instructions meticulously. Use appropriate calibration weights and ensure the scale is zeroed correctly before calibration. If issues persist, consult technical support.

Connectivity Issues

Check all connections and ensure that the system is properly integrated with your network infrastructure. Restarting the system or updating firmware may resolve connectivity problems.

Real-World Applications of UDS in the Packaging Industry

UDS systems are extensively utilized across various sectors within the packaging industry, including transportation, logistics, and inventory management. For example, in e-commerce fulfillment centers, UDS enables rapid and accurate package weighing, facilitating efficient order processing and shipping.

In logistics hubs, UDS aids in optimizing load distribution and transportation planning, ensuring that shipments are balanced and cost-effective. Inventory management systems benefit from UDS by maintaining precise stock levels and reducing discrepancies.

Conclusion

Ultrasonic Distance Sensor (UDS) systems offer significant advantages for package scales, including enhanced accuracy, efficiency, and integration capabilities. Proper setup, optimization, and management are essential to harness these benefits fully. By selecting the right UDS system and adhering to best practices, packaging facilities can achieve streamlined operations, cost savings, and improved customer satisfaction. As UDS technology continues to advance, its role in the packaging industry is poised to become even more pivotal, driving innovation and efficiency in logistics and supply chain management.