Managing Finished Goods Inventory for Maximum Efficiency

Efficient inventory management is paramount to the success of any business that deals in goods. It involves the intricate process of purchasing, storing, and selling various items. For businesses that primarily sell finished goods, managing their inventory becomes even more crucial. This article delves into the fundamentals of inventory management, highlights the importance of efficient finished goods inventory management, explores the common challenges businesses face, and outlines strategies to ensure maximum efficiency.

Understanding the Basics of Inventory Management

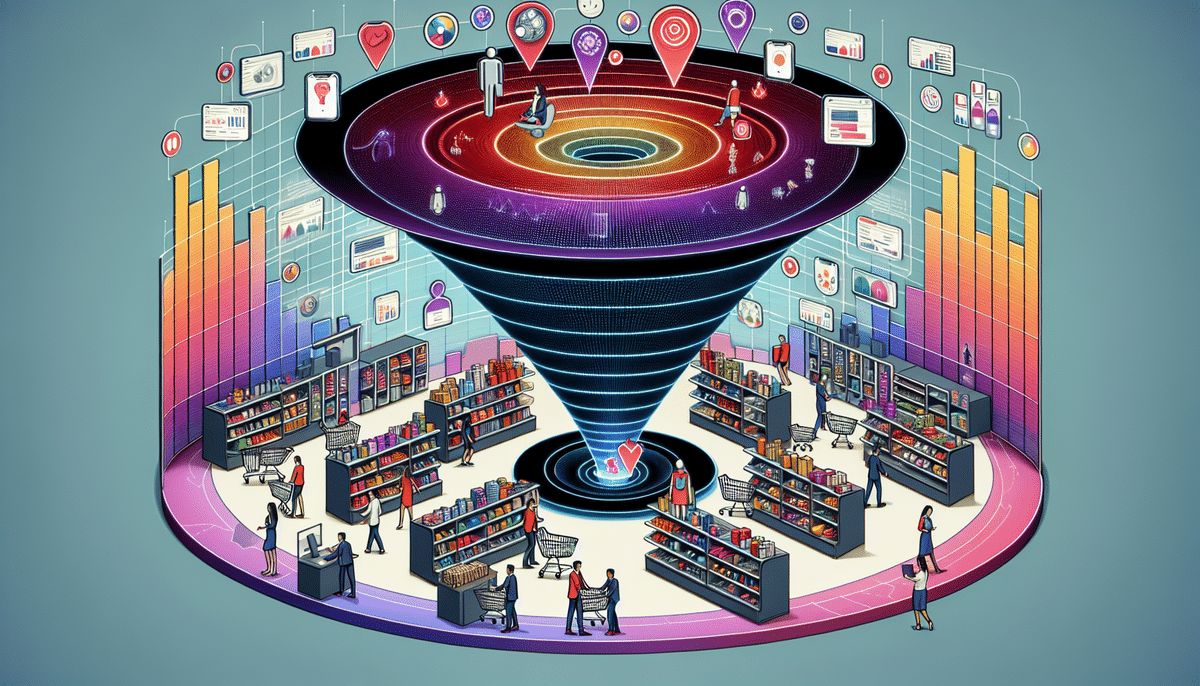

Inventory management encompasses the supervision of goods as they move into, through, and out of a business. This system includes ordering, storing, tracking, and selling inventory with the primary goal of maintaining optimal stock levels. Effective inventory management ensures that a business can meet customer demand without overstocking or experiencing stockouts, thereby optimizing operations and maximizing revenue.

Businesses achieve this by analyzing sales data to identify popular products and those that are underperforming. This analysis aids in making informed decisions about inventory ordering and timing. Moreover, leveraging inventory management software can automate tracking inventory levels and generating purchase orders, significantly enhancing accuracy and efficiency.

Proper storage of inventory is another critical aspect. Ensuring that inventory is kept in secure locations, protected from damage, and organized for easy retrieval can prevent losses and streamline operations. Regular physical inventory counts are also essential to verify that records align with actual inventory, reducing discrepancies and improving overall inventory accuracy.

Importance of Efficient Finished Goods Inventory Management

For businesses dealing primarily in finished goods, a streamlined inventory management system is crucial for success. Maintaining the right inventory levels helps avoid overstocking, which can lead to increased storage costs, and stockouts, which can result in lost sales and diminished customer satisfaction. Efficient inventory management not only boosts profits but also enhances a company's reputation for reliability and superior customer service.

One significant benefit is waste reduction. By accurately tracking inventory levels and ordering only what is necessary, businesses can prevent excess inventory from becoming obsolete. This practice not only saves on storage costs but also minimizes the environmental impact associated with excess waste.

Additionally, effective inventory management enhances forecasting and planning capabilities. Analyzing sales data and inventory levels provides insights into customer demand, allowing businesses to adjust production and inventory levels proactively. This proactive approach helps businesses stay competitive and better meet customer needs.

Common Challenges in Managing Finished Goods Inventory

Despite best efforts, managing finished goods inventory presents several challenges. One of the primary obstacles is accurately forecasting demand and sales. Predicting the right amount of inventory needed to meet customer demand without overstocking is a delicate balance that can significantly impact a business's bottom line.

Controlling costs and reducing waste also pose significant challenges. Overstocking leads to increased storage costs and potential waste, while stockouts can result in lost sales and damage to a company's reputation. Additionally, ensuring product quality and freshness is critical, especially for businesses dealing with perishable goods like food and pharmaceuticals. Proper storage and management are essential to prevent spoilage and ensure regulatory compliance.

Strategies for Effective Finished Goods Inventory Management

Accurate Demand Forecasting

Using historical sales data to forecast future demand is a fundamental strategy. Businesses can identify trends and predict customer demand, allowing for more accurate inventory ordering. Implementing forecasting software that utilizes advanced algorithms can further enhance forecasting accuracy.

Implementing Inventory Management Systems

Adopting robust inventory management software can automate tracking, ordering, and reporting processes. Systems like Enterprise Resource Planning (ERP) and Warehouse Management Systems (WMS) integrate various aspects of inventory management, improving overall efficiency.

Adopting Inventory Control Techniques

Techniques such as Just-In-Time (JIT) and Vendor-Managed Inventory (VMI) can help optimize inventory levels. JIT minimizes storage costs by receiving goods only as they are needed, while VMI delegates inventory management responsibilities to suppliers, enhancing collaboration and reducing costs.

Regular Inventory Audits

Conducting periodic physical inventory counts ensures that actual inventory levels match recorded data. Regular audits help identify discrepancies, prevent theft, and maintain inventory accuracy.

The Role of Technology in Streamlining Inventory Management

Technology plays a pivotal role in modern inventory management. Advanced inventory management software offers real-time tracking, automated reordering, and comprehensive reporting features. Technologies like Radio Frequency Identification (RFID) and barcode scanning enhance accuracy in tracking inventory movements.

Additionally, integrating artificial intelligence and machine learning into inventory systems can further optimize demand forecasting and inventory replenishment processes. These technologies analyze vast amounts of data to predict trends and make informed inventory decisions, reducing human error and increasing efficiency.

Future Trends and Innovations in Finished Goods Inventory Management

The landscape of inventory management is continually evolving with advancements in technology. Future trends to watch include the increased integration of machine learning and artificial intelligence to enhance predictive analytics and demand forecasting. Robotics and automation are also set to play a significant role in warehouse management, improving speed and accuracy in order fulfillment.

Moreover, the adoption of blockchain technology promises to enhance transparency and traceability in supply chains, ensuring the authenticity and quality of finished goods. Embracing these innovations can provide businesses with a competitive edge, enabling them to manage their inventories more effectively and respond swiftly to market changes.

Conclusion

Efficient finished goods inventory management is crucial for the success of businesses dealing in tangible products. By maintaining optimal stock levels, controlling costs, and minimizing waste, businesses can enhance their operational efficiency, increase profits, and improve customer satisfaction. Leveraging the latest technological tools and continuously refining inventory management practices will enable businesses to stay competitive in an ever-evolving market. Implementing robust inventory management strategies not only boosts financial performance but also builds a reputation for reliability and excellence in customer service.