Optimizing Milk Run Logistics for Maximum Efficiency

In today's fast-paced and ever-evolving business environment, companies continuously seek strategies to gain a competitive advantage. One effective approach is optimizing logistics processes and supply chain management. Milk run logistics is an increasingly popular concept that aims to maximize efficiency while reducing costs and waste. This article delves into the concept of milk run logistics, its benefits, key considerations for implementation, and best practices to ensure successful execution.

Understanding Milk Run Logistics and Its Significance

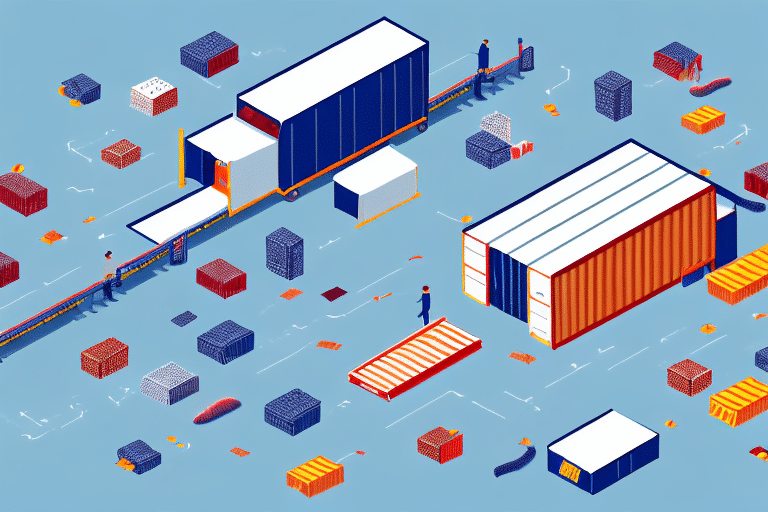

Milk run logistics involves the collection and delivery of materials and products to multiple destinations within a single trip. Inspired by the traditional milk delivery routes from dairy farms, this method streamlines supply chain operations by consolidating deliveries, thereby reducing transportation costs and ensuring timely deliveries.

Instead of each supplier dispatching individual trucks to the same customer, a single truck makes multiple stops to gather materials from different suppliers along a fixed route. This consolidation minimizes the number of vehicles on the road, leading to lower emissions and reduced traffic congestion, making milk run logistics an environmentally sustainable option.

Moreover, milk run logistics enhances inventory management. By synchronizing deliveries, businesses can maintain optimal inventory levels, reducing the risk of stockouts and minimizing excess inventory. This improvement not only cuts costs but also boosts operational efficiency.

Benefits of Implementing Milk Run Logistics

Cost Reduction

One of the primary advantages of milk run logistics is the substantial reduction in transportation costs. By consolidating multiple deliveries into a single trip, companies can save on fuel, labor, and vehicle maintenance expenses. According to a Supply Chain Quarterly report, businesses can achieve up to a 20% reduction in logistics costs through effective milk run strategies.

Environmental Sustainability

Milk run logistics contributes to lower carbon emissions by decreasing the number of trucks required for deliveries. This reduction not only supports corporate sustainability goals but also complies with increasingly stringent environmental regulations. The Environmental Protection Agency emphasizes the importance of such strategies in mitigating environmental impact.

Enhanced Inventory Management

By enabling more frequent and reliable deliveries, milk run logistics allows businesses to maintain leaner inventories. This approach minimizes holding costs and reduces the likelihood of obsolescence, contributing to improved financial performance.

Improved Supplier and Customer Relationships

Regular and predictable delivery schedules foster stronger relationships between suppliers and customers. Consistent interactions enhance collaboration, leading to better communication and increased trust among stakeholders.

Common Challenges and Solutions in Milk Run Logistics

Planning and Scheduling

Effective planning and scheduling are critical for the success of milk run logistics. Coordinating multiple delivery points requires meticulous organization to ensure timely and accurate deliveries. Implementing advanced route optimization software can significantly enhance scheduling efficiency.

Route Optimization

Designing optimal delivery routes is essential to maximize efficiency and minimize costs. Factors such as distance, traffic patterns, and delivery time windows must be considered. Utilizing data analytics and GPS tracking systems can aid in developing the most efficient routes.

Unforeseen Disruptions

Unexpected events like traffic congestion, adverse weather, or vehicle breakdowns can disrupt milk run logistics operations. Establishing contingency plans and maintaining real-time communication with all stakeholders can help mitigate these risks.

Balancing Cost and Service Levels

While milk run logistics is cost-effective, it is crucial to ensure that service levels meet customer expectations. Regularly assessing and adjusting logistics strategies based on customer feedback and performance metrics can help maintain the right balance.

Key Factors to Consider When Implementing Milk Run Logistics

- Volume and Frequency of Deliveries: Assessing the required volume and frequency helps in designing an effective milk run schedule.

- Geographic Location: Understanding the spatial distribution of suppliers and customers is vital for route planning.

- Product Types and Handling Requirements: Different products may have specific handling and storage needs that must be accommodated.

- Vehicle Capacity and Capabilities: Ensuring that delivery vehicles are suitable for the planned routes and cargo is essential.

- Delivery Timing and Scheduling: Coordinating delivery times to align with production schedules and customer demand is critical.

Additionally, fostering strong communication and collaboration with suppliers and customers is paramount. Effective information sharing ensures that all parties are aligned with the delivery schedules and can promptly address any changes or issues.

Leveraging Technology to Streamline Milk Run Logistics

Technological advancements play a pivotal role in enhancing milk run logistics operations. Implementing Internet of Things (IoT) devices and real-time tracking systems can provide valuable insights into delivery progress and vehicle performance.

Route optimization software analyzes various data points to determine the most efficient delivery paths, reducing travel time and fuel consumption. Additionally, automated inventory management systems ensure that inventory levels are continuously monitored and replenished as needed.

Embracing these technologies not only improves operational efficiency but also enhances the overall reliability and responsiveness of the supply chain.

Best Practices for Implementing and Managing Milk Run Logistics

- Partner with Reliable Stakeholders: Collaborate with dependable suppliers and customers to ensure consistency and reliability in deliveries.

- Invest in Advanced Tools and Technologies: Utilize state-of-the-art supply chain management tools to enhance planning, tracking, and optimization.

- Develop a Comprehensive Delivery Schedule: Create detailed and flexible delivery schedules that can adapt to changing demands and conditions.

- Regularly Analyze Performance Data: Continuously monitor and evaluate logistics performance to identify areas for improvement.

- Optimize Routes Continuously: Regularly revisit and refine delivery routes based on new data and evolving conditions.

- Maintain Open Communication Channels: Ensure transparent and consistent communication among all parties involved in the logistics process.

By adhering to these best practices, businesses can effectively implement and manage milk run logistics, resulting in enhanced efficiency and significant cost savings.

Case Study: Toyota's Successful Implementation of Milk Run Logistics

Toyota, a global leader in the automotive industry, has successfully implemented a milk run logistics system within its manufacturing operations. By delivering parts and materials directly to assembly lines through a coordinated milk run schedule, Toyota has achieved remarkable efficiencies.

The implementation of this system has led to a significant reduction in transportation costs and minimized unnecessary handling of materials. Additionally, Toyota's commitment to sustainability is reflected in the decreased carbon emissions resulting from fewer vehicle trips.

Furthermore, the milk run logistics system has enhanced Toyota's inventory management capabilities. With a predictable and regular delivery schedule, the company maintains optimal inventory levels, reducing holding costs and improving cash flow. Enhanced collaboration between Toyota and its suppliers has also strengthened relationships and fostered greater trust.

For more details on Toyota's logistics strategies, refer to the Toyota Production System.

Future Trends in Milk Run Logistics and Their Impact

As businesses strive to enhance their supply chain operations, milk run logistics is poised for further growth and innovation. Emerging trends such as automation, robotics, and artificial intelligence are set to revolutionize milk run logistics, driving even greater efficiencies and cost savings.

The increasing use of Artificial Intelligence (AI) and machine learning will enable more sophisticated route optimization and predictive analytics, allowing businesses to anticipate and respond to potential disruptions proactively.

Data analytics will play a crucial role in refining milk run logistics operations. By analyzing data on delivery times, vehicle performance, and supply chain dynamics, companies can continuously optimize their logistics strategies to enhance performance and customer satisfaction.

Additionally, the growing emphasis on sustainability will drive the adoption of green logistics practices within milk run systems. Businesses will increasingly seek to minimize their environmental impact by adopting electric or hybrid delivery vehicles and implementing energy-efficient logistics technologies.

Conclusion: The Strategic Advantage of Adopting Milk Run Logistics

Milk run logistics offers a strategic advantage for businesses aiming to maximize efficiency, reduce costs, and enhance sustainability within their supply chain operations. By consolidating deliveries, optimizing routes, and leveraging advanced technologies, companies can achieve significant operational improvements and cost savings.

Implementing milk run logistics requires careful planning, effective collaboration, and ongoing optimization. However, the long-term benefits—ranging from reduced transportation costs and lower carbon emissions to improved inventory management and stronger supplier relationships—make it a compelling strategy for businesses of all sizes.

As the business landscape continues to evolve, adopting milk run logistics will become increasingly vital for companies seeking to maintain a competitive edge and achieve sustainable growth. Embracing this logistics model not only enhances operational efficiency but also supports broader corporate goals related to sustainability and customer satisfaction.