Why Operational Efficiency Matters in In-house Operations

Operational efficiency is a critical factor in the success of any organization. By optimizing in-house operations, businesses can streamline processes, reduce costs, and enhance productivity. According to a report by McKinsey & Company, companies that prioritize operational efficiency can achieve up to a 30% reduction in operational costs.

Benefits of Operational Efficiency

- Increased Productivity: Efficient processes enable employees to accomplish more with less effort.

- Cost Reduction: Streamlining operations helps in minimizing waste and reducing expenses.

- Enhanced Quality: Consistent processes lead to higher quality outputs and fewer errors.

- Improved Customer Satisfaction: Efficient operations ensure timely delivery and better service quality.

Assessing the Current State of Your In-house Operations

Before implementing any improvements, it's essential to thoroughly assess the current state of your operations. This involves evaluating workflows, technology utilization, personnel effectiveness, and overall process efficiency.

Conducting a Workflow Analysis

Analyze existing workflows to identify bottlenecks and redundancies. Tools like workflow analysis frameworks can help in mapping out processes and pinpointing inefficiencies.

Evaluating Technology and Tools

Assess the effectiveness of current technology and tools. Upgrading to more advanced systems can automate repetitive tasks and improve data management.

Measuring Employee Engagement

Engaged employees are more productive and committed to the organization's success. Utilizing surveys and feedback mechanisms can help measure and enhance employee engagement (Harvard Business Review).

Strategies for Improving Operational Efficiency

Once the assessment is complete, organizations can implement various strategies to enhance operational efficiency.

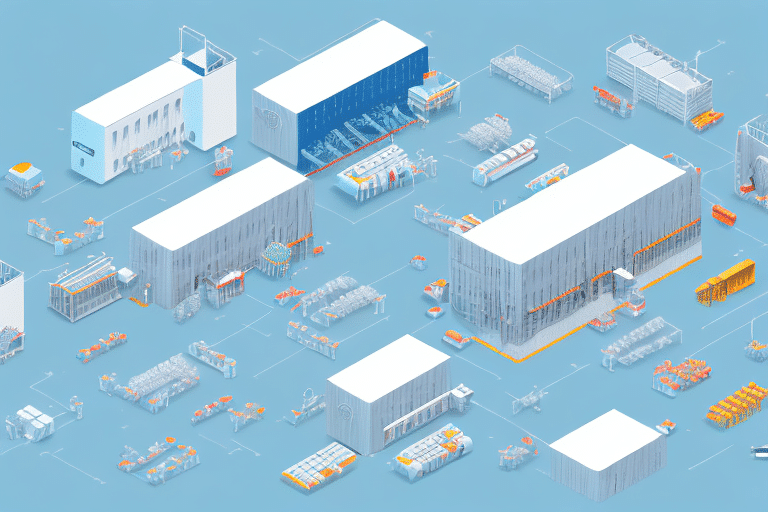

Optimizing Supply Chain Management

Efficient supply chain management ensures timely procurement and delivery of goods, reducing inventory costs and improving customer satisfaction.

Enhancing Quality Control

Implementing robust quality control measures helps in maintaining consistency and reducing defects.

Streamlining Project Management

Adopting effective project management methodologies, such as Agile or Lean, can improve project completion rates and performance.

Implementing Lean Methodologies

Lean methodologies focus on eliminating waste and enhancing value through continuous improvement.

Value Stream Mapping

Identify value-added and non-value-added activities in your processes to streamline operations.

Continuous Improvement (Kaizen)

Encourage a culture of ongoing improvement where employees regularly suggest and implement small changes.

Using Visual Management Tools

Tools like Kanban boards help teams visualize workflows and identify areas for improvement (Lean Enterprise Institute).

Leveraging Technology to Enhance Efficiency

Modern technology plays a pivotal role in driving operational efficiency.

Automation and Robotics

Automating repetitive tasks reduces manual labor and minimizes errors, freeing up employees for more strategic work.

Data Analytics

Utilizing data analytics helps organizations make informed decisions by providing insights into operational performance.

Cloud Computing

Cloud-based solutions offer scalability and flexibility, allowing businesses to adapt quickly to changing demands (Microsoft Azure).

Measuring Success: Key Metrics for Operational Efficiency

Tracking the right metrics is essential to measure the success of operational efficiency initiatives.

Cycle Time

The total time taken to complete a process from start to finish. Reducing cycle time leads to faster delivery and increased throughput.

Defect Rate

The percentage of products or services that fail to meet quality standards. Lower defect rates indicate higher quality and efficiency.

Employee Productivity

Measuring the output per employee helps in understanding workforce efficiency and identifying areas for improvement.

Cost Savings

Tracking cost reductions achieved through operational improvements helps in quantifying the financial benefits.

Building a Culture of Continuous Improvement

Sustaining operational efficiency requires fostering a culture that embraces continuous improvement.

Encouraging Employee Involvement

Empower employees to identify inefficiencies and contribute to solutions. This enhances engagement and ownership.

Regular Feedback Loops

Implementing mechanisms for regular feedback ensures ongoing assessment and timely adjustments to processes.

Providing Training and Development

Investing in employee training equips the workforce with the skills needed to implement and sustain efficiency improvements.

Overcoming Challenges in Implementing Operational Efficiency

Improving operational efficiency is not without its challenges. Effective change management is crucial to overcome resistance and ensure successful implementation.

Managing Change Effectively

Communicate the benefits of changes clearly and involve employees in the process to mitigate resistance.

Avoiding Common Pitfalls

Ensure that goals are clear, metrics are defined, and improvements are sustained over time to avoid common inefficiency pitfalls.

Conclusion: Steps to Drive Operational Efficiency Today

Enhancing operational efficiency in in-house operations can lead to significant improvements in productivity, cost reduction, and customer satisfaction. By assessing current operations, implementing effective strategies, leveraging technology, and fostering a culture of continuous improvement, organizations can achieve sustainable efficiency gains and maintain a competitive edge in the market.