Measuring On-Hand Inventory Value and Its Importance in E-Commerce Operations

In the competitive landscape of e-commerce, maintaining an optimal level of on-hand inventory is paramount to meeting customer demand and sustaining business growth. However, it's not sufficient to merely stock products; accurately tracking the value of your inventory is equally critical. Precise measurement of on-hand inventory value provides essential insights into the financial health of your business, guiding strategic decisions that can enhance profitability and operational efficiency.

The Importance of Accurate On-Hand Inventory Valuation

Accurate valuation of on-hand inventory allows e-commerce businesses to assess their financial standing by understanding the capital tied up in inventory. According to a 2023 Statista study, businesses with precise inventory valuation report up to 15% higher profitability compared to those with inaccurate inventory tracking.

Proper inventory valuation aids in making informed financial decisions, such as managing cash flow, budgeting for future investments, and optimizing operational costs. Without it, companies risk miscalculating their assets, leading to either overvaluation or undervaluation of inventory, which can distort financial statements and result in poor business decisions.

Moreover, accurate inventory valuation is essential for effective supply chain management. It enables businesses to streamline ordering processes, reduce lead times, and enhance customer satisfaction by ensuring that products are available when needed.

Methods for Calculating On-Hand Inventory Value

There are several established methods for calculating the value of on-hand inventory, each with its own advantages and applicability depending on the nature of the business.

Cost of Goods Sold (COGS)

The COGS method calculates the direct costs attributable to the production of goods sold by a company. This includes the cost of raw materials, labor, and overhead expenses directly tied to product manufacturing. Accurate COGS calculation is vital for determining gross profit and overall business profitability.

First-In, First-Out (FIFO)

The FIFO method assumes that the first items added to inventory are the first sold. This approach aligns with the natural flow of goods, especially for perishable items, and often results in lower COGS during periods of rising prices. For more information on FIFO, refer to the FIFO method explained by AccountingTools.

Last-In, First-Out (LIFO)

LIFO assumes that the most recently added inventory items are sold first. This method can offer tax advantages in certain jurisdictions during inflationary periods by matching current higher costs against revenues. However, LIFO is not permitted under International Financial Reporting Standards (IFRS). Learn more from Investopedia.

Weighted Average Cost

The weighted average cost method calculates inventory value by taking the average cost of all inventory items, considering both the cost and quantity of each item. This method smooths out price fluctuations and is suitable for businesses dealing with large volumes of similar items. For a deeper understanding, see Investopedia.

Choosing the right inventory valuation method depends on various factors, including the nature of the products, market conditions, and the specific financial goals of the business. Consistency in applying the chosen method is crucial for accurate financial reporting and analysis.

Common Challenges in E-Commerce Inventory Management

Accurately valuing and managing inventory in an e-commerce environment presents several unique challenges.

Multi-Channel Sales Complexity

Operating across multiple sales channels, such as online marketplaces, own websites, and physical stores, complicates inventory tracking. Synchronizing inventory levels in real-time across all platforms is essential to prevent discrepancies that can lead to stockouts or overstocking.

Demand Forecasting and Market Trends

Predicting consumer demand accurately is challenging due to rapidly changing market trends and consumer preferences. Overestimation can lead to excess inventory, while underestimation may result in stockouts and lost sales.

Seasonal Fluctuations

Seasonal variations significantly impact inventory levels. Preparing for peak seasons while managing inventory during off-peak periods requires strategic planning and precise valuation to maintain profitability throughout the year.

Inventory Shrinkage

Losses due to theft, damage, or mismanagement can distort inventory values and negatively impact financial reporting. Implementing robust inventory control measures is essential to minimize shrinkage.

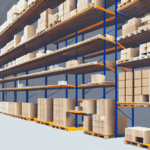

Best Practices for Measuring and Managing Inventory Value

Implementing best practices in inventory management can enhance accuracy and efficiency in valuing on-hand inventory.

Utilize Advanced Inventory Management Software

Adopting sophisticated inventory management systems enables real-time tracking, automated reorder points, and integration with various sales channels. These systems improve accuracy and reduce manual errors. Industry leaders such as Shopify Inventory Management offer comprehensive solutions tailored for e-commerce businesses.

Regular Stock Audits

Conducting periodic physical inventory counts helps verify the accuracy of inventory records. Regular audits identify discrepancies early, allowing for timely corrective actions.

Just-In-Time (JIT) Inventory Strategy

The JIT approach minimizes storage costs by receiving goods only as they are needed in the production process. This strategy reduces the capital tied up in inventory and lowers the risk of overstocking.

Optimize Reorder Points and Safety Stock

Establishing appropriate reorder points and maintaining safety stock levels ensure that inventory is replenished promptly without overstocking. Advanced analytics can aid in setting these parameters based on sales data and demand forecasts.

The Role of Technology in Inventory Valuation

Technology plays a pivotal role in enhancing the accuracy and efficiency of inventory valuation in e-commerce operations.

Automation and Real-Time Tracking

Automated inventory systems provide real-time visibility into inventory levels, reducing the likelihood of human error and enabling swift response to stock level changes. Tools like barcode scanners and RFID technology facilitate accurate tracking of inventory movements.

Data Analytics and Forecasting Tools

Advanced data analytics help in forecasting demand trends, optimizing inventory levels, and making informed purchasing decisions. Machine learning algorithms can analyze historical sales data to predict future demand more accurately.

Integration with E-commerce Platforms

Integrating inventory management systems with e-commerce platforms ensures seamless data flow between sales channels and inventory records. This integration enhances operational efficiency and provides a unified view of inventory across all platforms.

For more insights on inventory management technology, refer to the Harvard Business Review's article on inventory management technology.

Key Metrics for Effective Inventory Management

Monitoring key performance indicators (KPIs) is essential for assessing the effectiveness of inventory management practices.

Inventory Turnover Rate

This metric indicates how many times inventory is sold and replaced over a specific period. A higher turnover rate reflects efficient inventory management, whereas a lower rate may signal overstocking issues. According to a 2023 Statista report, the average inventory turnover rate for e-commerce businesses is approximately 6 times per year.

Gross Margin Return on Investment (GMROI)

GMROI measures the profitability of inventory by comparing the gross margin earned against the investment in inventory. A higher GMROI signifies better inventory profitability.

Days of Inventory (DOI)

DOI calculates the average number of days it takes to sell the entire inventory. This metric helps businesses understand how effectively inventory is being managed and identify opportunities for improvement.

Stockout Rate

The stockout rate measures the frequency at which inventory items are unavailable for sale. Minimizing stockouts is crucial for maintaining customer satisfaction and avoiding lost sales.

Carrying Cost of Inventory

Carrying costs encompass expenses related to storing, handling, and insuring inventory. Monitoring these costs helps businesses balance the benefits of having sufficient inventory against the financial burden of holding it.

Tracking these metrics enables e-commerce businesses to identify trends, assess operational efficiency, and implement strategies for continuous improvement in inventory management.

Strategies to Optimize Inventory and Boost E-Commerce Sales

Optimizing inventory levels not only streamlines operations but also enhances customer satisfaction and drives sales growth.

Implement Just-In-Time (JIT) Inventory Management

JIT minimizes excess inventory by aligning stock levels with actual demand. This approach reduces storage costs and decreases the risk of inventory obsolescence.

Expand Product Range Strategically

Introducing new and complementary product lines can attract a broader customer base and increase sales. However, it's essential to assess demand and avoid overextending inventory resources.

Bundle Products and Offer Promotions

Bundling products or running targeted promotions can help move slow-moving inventory and boost overall sales. These strategies can also enhance perceived value for customers.

Enhance Supplier Relationships

Strong relationships with suppliers facilitate better negotiation terms, faster replenishment, and improved product quality. Reliable suppliers are critical for maintaining optimal inventory levels.

Leverage Data-Driven Decision Making

Utilizing data analytics to inform purchasing and inventory decisions ensures that strategies are grounded in accurate and actionable insights.

The Impact of Seasonality on Inventory Management in E-Commerce

Seasonal trends significantly influence inventory planning and valuation in the e-commerce sector. Understanding and adapting to these fluctuations is essential for maintaining profitability throughout the year.

Peak Seasons

During peak seasons like holidays, inventory demand surges, requiring businesses to scale up stock levels proactively. Accurate forecasting and timely replenishment are crucial to capitalize on increased sales opportunities.

Off-Peak Strategies

In off-peak periods, managing inventory involves minimizing carrying costs and preventing overstocking. Strategies include offering discounts, liquidating excess inventory, and focusing on marketing efforts to stimulate demand.

Adaptive Forecasting

Adapting forecasting models to account for seasonal variations ensures that inventory levels are aligned with expected demand. Incorporating historical sales data and market trends enhances the accuracy of these predictions.

Effective seasonality management helps e-commerce businesses maintain a balanced inventory, reduce costs, and maximize sales potential year-round.

Real-Life Success Stories in Inventory Valuation

Examining successful e-commerce companies showcases the benefits of effective inventory valuation and management practices.

Amazon

Amazon employs advanced inventory forecasting tools and robotics in its fulfillment centers to maintain optimal inventory levels. By leveraging big data and machine learning, Amazon accurately predicts demand patterns, reduces lead times, and enhances customer satisfaction.

Shopify

Shopify's integrated inventory management system allows e-commerce businesses to automate inventory tracking, manage multiple sales channels, and gain real-time insights into inventory performance. This system enables merchants to maintain optimal stock levels and streamline their operations effectively.

Walmart

Walmart utilizes a combination of data analytics and supply chain optimization to manage its vast inventory efficiently. Their sophisticated systems enable real-time inventory tracking, dynamic pricing adjustments, and seamless integration across global distribution centers.

These examples highlight how investing in robust inventory management systems and adopting data-driven strategies can lead to significant operational efficiencies and enhanced profitability in the e-commerce industry.

In conclusion, accurately measuring on-hand inventory value is integral to the success of e-commerce operations. By understanding various valuation methods, overcoming common challenges, implementing best practices, leveraging technology, and monitoring key metrics, businesses can optimize their inventory management processes. This not only reduces costs and increases efficiency but also drives sales growth and enhances customer satisfaction. Embracing these strategies and learning from industry leaders can position e-commerce businesses for sustained success in a dynamic marketplace.