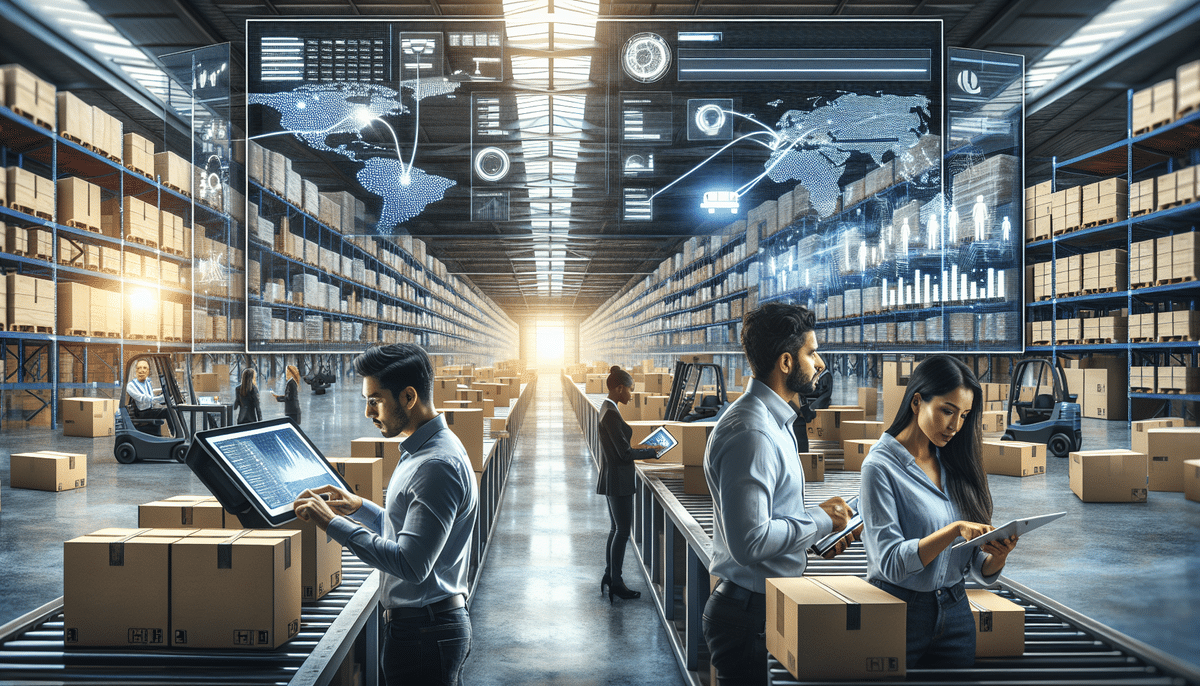

Outsourcing Inventory Management: Enhancing Efficiency and Reducing Costs

In today's globalized economy, businesses continually seek strategies to streamline operations and boost profitability. Outsourcing inventory management has emerged as a popular approach, offering numerous benefits while presenting certain challenges. This article delves into the advantages and potential drawbacks of outsourcing your inventory management, key factors in selecting the right outsourcing partner, and best practices to ensure success.

The Benefits of Outsourcing Inventory Management

Focus on Core Competencies

Outsourcing inventory management allows businesses to concentrate on their primary strengths, such as product development and customer service, by delegating the complexities of inventory handling to specialized third-party providers.

Cost Reduction

By eliminating the need for specialized staff, software licenses, and infrastructure, companies can significantly reduce overhead costs. According to a McKinsey report, businesses can achieve up to 30% cost savings through effective outsourcing strategies.

Supply Chain Efficiency

Third-party providers leverage their expertise and advanced technologies to optimize inventory levels, reduce lead times, and enhance order fulfillment processes. This leads to faster delivery times, fewer stockouts, and improved customer satisfaction.

Flexibility and Scalability

Outsourcing partners can quickly adapt to business growth or fluctuations in demand, ensuring that inventory levels and supply chain processes align with evolving business needs without the risks associated with overextending resources.

Challenges of Outsourcing Inventory Management

Loss of Control

Delegating inventory management can result in reduced oversight, potentially affecting the quality and responsiveness of inventory processes. It's crucial to establish clear communication channels and performance metrics to mitigate this risk.

Data Security Risks

Entrusting inventory data to external partners poses potential security threats. Implementing robust data protection measures and selecting partners with strong security protocols is essential to safeguard sensitive information.

Communication and Cultural Barriers

Differences in business practices and communication styles can lead to misunderstandings and inefficiencies. Ensuring cultural compatibility and maintaining regular communication can help bridge these gaps.

Selecting the Right Outsourcing Partner

Experience and Expertise

Choose a provider with a proven track record and specialized expertise in inventory management relevant to your industry. Reviewing case studies and client testimonials can provide insights into their capabilities.

Technology and Automation

Ensure that the outsourcing partner utilizes advanced inventory management systems, such as RFID technology and automated picking systems, to enhance accuracy and efficiency.

Scalability and Flexibility

Assess the provider’s ability to scale services in line with your business growth and adapt to your specific operational requirements.

Transparency and Pricing

Opt for partners who offer transparent pricing models and comprehensive service agreements, minimizing the risk of hidden costs and ensuring alignment with your budget.

Compliance and Standards

Verify that the outsourcing partner adheres to relevant industry regulations and standards, ensuring legal compliance and maintaining the integrity of your inventory processes.

Implementing Best Practices for Successful Outsourcing

Clear Contract and SLAs

Establish detailed contracts and Service Level Agreements (SLAs) that outline expectations, deliverables, and performance metrics to ensure accountability and clarity.

Regular Communication

Maintain consistent communication through scheduled meetings, reports, and feedback channels to monitor progress and address issues promptly.

Risk Management

Develop contingency plans and implement risk mitigation strategies to handle potential disruptions, ensuring continuity in inventory management operations.

Performance Monitoring

Track key performance indicators (KPIs) such as inventory turnover rates, order accuracy, and fulfillment times to evaluate the effectiveness of the outsourcing arrangement.

Leveraging Technology in Outsourced Inventory Management

Technology is integral to modern inventory management outsourcing. Advanced software solutions provide real-time visibility into inventory levels, demand forecasting, and supply chain analytics. Implementing systems like SAP Inventory Management or Oracle SCM can enhance accuracy, speed, and decision-making capabilities.

Case Studies: Success Stories in Inventory Management Outsourcing

Numerous businesses have reaped significant benefits from outsourcing their inventory management:

- Large E-commerce Retailer: Reduced inventory holding costs and shipping times by partnering with a specialized fulfillment provider.

- Restaurant Chain: Improved inventory accuracy and minimized waste through centralized procurement with an external supplier.

- Fashion Brand: Expanded global reach by leveraging an outsourced logistics partner experienced in international shipping and customs compliance.

Conclusion: Making the Right Choice for Your Business

Outsourcing inventory management can offer substantial benefits, including cost savings, enhanced efficiency, and the ability to focus on core business activities. However, it's essential to approach outsourcing with a strategic mindset, carefully selecting the right partner and implementing best practices to mitigate potential challenges. By doing so, businesses can optimize their inventory management processes, drive growth, and achieve sustained competitive advantage.