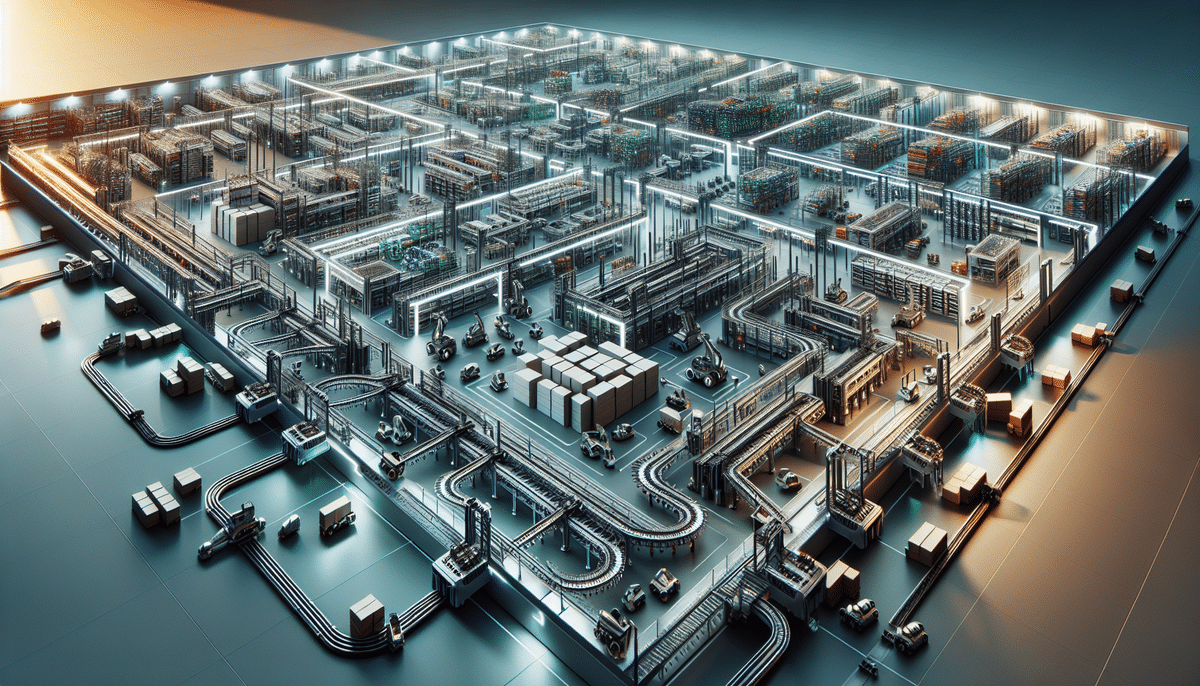

The Rise of Automated Warehouses

The demand for automated warehouses has surged in recent years, driven by the need to enhance efficiency and productivity. Automated systems delegate routine tasks to machines, allowing employees to focus on more complex responsibilities such as quality control and customer service. This shift not only saves time but also reduces errors, as machines are less prone to mistakes compared to human workers. Additionally, automated warehouses offer scalability, enabling businesses to expand their operations seamlessly to meet growing demands.

Furthermore, automated warehouses contribute to a safer working environment by minimizing the risk of accidents and injuries. Machines can handle heavy loads and hazardous materials, eliminating the need for human intervention in potentially dangerous tasks. This not only safeguards employees but also reduces business liability in case of workplace incidents. As automation technology continues to evolve, more businesses are adopting automated warehouse solutions to stay competitive and ensure long-term sustainability.

Understanding Knapp and AutoStore Automated Systems

Basic Concepts

Knapp and AutoStore are two leading automated warehouse systems designed to optimize warehouse operations. Knapp utilizes a modular approach, incorporating conveyor belts, shuttles, and robots to automate the movement and sorting of goods. In contrast, AutoStore employs a fully robotic system where small bots navigate the warehouse to transport storage bins efficiently.

Key Features

- Knapp: Offers high flexibility through its modular design, allowing easy customization and expansion. It supports high-speed order picking and sorting, enhancing the speed of order fulfillment.

- AutoStore: Known for its space-efficient design, AutoStore maximizes storage capacity by stacking bins vertically and utilizing narrow aisles. Its software optimizes item placement based on demand, improving retrieval times for popular products.

Comparing Efficiency and Sustainability

Warehouse Efficiency

Both Knapp and AutoStore significantly boost warehouse efficiency by automating routine tasks and reducing human error. Knapp's customizable modules provide tailored solutions for diverse business needs, while AutoStore's precise robotic movements optimize space utilization and inventory management.

Sustainability Initiatives

In addition to operational efficiency, both systems emphasize sustainability. Knapp focuses on optimizing energy usage and minimizing waste, whereas AutoStore utilizes rechargeable batteries to power its robots, reducing reliance on fossil fuels. Both companies are committed to using eco-friendly materials in their products and packaging, contributing to a more sustainable future.

Pros and Cons of Knapp and AutoStore Systems

Knapp Systems

- Pros: Highly customizable and flexible, suitable for a wide range of business needs; scalable to accommodate growth; high-speed order processing.

- Cons: Requires more floor space; more complex to operate and maintain compared to AutoStore.

AutoStore Systems

- Pros: Space-efficient design; easier to operate; optimized for rapid retrieval of frequently ordered items.

- Cons: Limited customization options; higher upfront costs; maintenance can be more expensive.

Making the Right Choice for Your Business

Choosing between Knapp and AutoStore depends on various factors, including the size of your business, the nature of your inventory, and your budget. For instance:

- Inventory Type: If your business handles small parts requiring quick storage and retrieval, AutoStore might be more suitable.

- Customization Needs: Businesses dealing with diverse or large items may benefit from Knapp's flexible solutions.

- Automation Level: AutoStore offers higher automation with minimal human intervention, ideal for businesses aiming to reduce labor costs.

Additionally, consider the long-term costs and scalability of each system. While AutoStore may require a higher initial investment, its efficiency can lead to cost savings over time. Knapp offers a more affordable upfront option but may incur higher maintenance costs as your operations grow.

Cost, Maintenance, and Scalability: Knapp vs AutoStore

Cost Comparison

The implementation cost of automated warehouse systems varies based on factors like warehouse size and customization needs. Generally, AutoStore systems have higher upfront costs but lower maintenance expenses. Conversely, Knapp systems are less expensive initially but may require more ongoing maintenance.

Maintenance Requirements

Both systems necessitate regular maintenance to ensure optimal performance. Knapp systems require mechanical upkeep, such as cleaning conveyor belts and replacing worn parts. AutoStore systems need periodic battery replacements and system checks to maintain their robotic operations.

Scalability

Both Knapp and AutoStore offer scalable solutions to support business growth. Knapp's modular design allows for easy expansion and customization, making it suitable for businesses with evolving inventory needs. AutoStore's space-efficient system is ideal for businesses anticipating significant growth while maintaining a compact warehouse footprint.

Integration and Future Trends

System Integration

Integrating automated systems with existing warehouse management systems (WMS) is crucial for seamless operations. Knapp systems are compatible with various WMS platforms, facilitating easier integration into current workflows. On the other hand, AutoStore systems utilize proprietary software, which may present challenges when integrating with external systems but offers streamlined management within their ecosystem.

Future of Automated Warehouses

Experts anticipate that the future of automated warehouses will feature advancements in artificial intelligence and machine learning, further enhancing inventory management and space optimization. The growth of e-commerce continues to drive demand for faster delivery times, increasing the reliance on sophisticated automated systems like Knapp and AutoStore. Both companies are at the forefront of these innovations, continually improving their technologies to meet evolving market needs.

Customer Success Stories

Real-life implementations highlight the effectiveness of both Knapp and AutoStore systems:

- Adidas: Implemented a Knapp system in its warehouse, resulting in a 50% increase in efficiency and a 99.9% order accuracy rate.

- Ocado: British online retailer Ocado adopted an AutoStore system, enabling the storage of over 40,000 products in a compact space and achieving a 70% increase in throughput.

These success stories demonstrate that both Knapp and AutoStore can significantly enhance warehouse productivity and operational accuracy.

Conclusion: Making the Right Choice for Your Business

In summary, both Knapp and AutoStore offer robust automated warehouse solutions that can transform your business operations. The optimal choice depends on factors such as warehouse size, inventory type, budget, and long-term scalability needs. By carefully evaluating these aspects and considering the unique strengths of each system, you can select the solution that best aligns with your business goals and operational requirements. Investing in the right automated warehouse system is a strategic decision that can drive efficiency, reduce costs, and support sustainable growth.