Understanding UPS Dimensional Weight: A Comprehensive Guide

As e-commerce continues to thrive, shipping costs play a crucial role in business operations. One key factor influencing these costs is dimensional weight, a pricing methodology used by carriers like UPS. This guide provides an in-depth analysis of UPS dimensional weight, offering detailed explanations, data-driven insights, and actionable tips to help you optimize your shipping strategy.

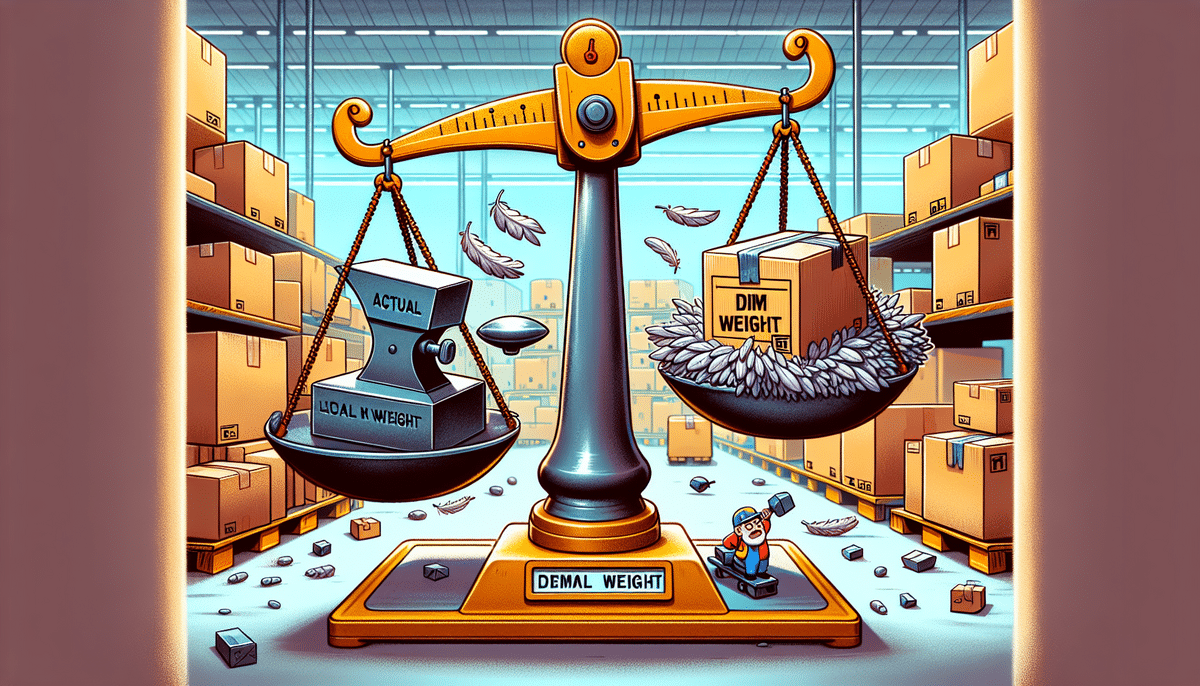

What is Dimensional Weight?

Dimensional weight, or DIM weight, is a pricing technique that considers a package's volume alongside its actual weight. Instead of charging solely based on the package’s physical weight, carriers calculate dimensional weight to account for the space a package occupies in their delivery vehicles.

For instance, a lightweight but bulky package may incur higher shipping costs compared to a heavier, compact one. This system ensures that carriers can maximize space efficiency, ultimately providing fair pricing based on both weight and size.

How UPS Calculates Dimensional Weight

UPS uses specific formulas to determine dimensional weight, which vary based on the shipment's destination and service type:

- Domestic Shipments: Dimensional weight is calculated using the formula (Length x Width x Height) / 139. The result is compared to the actual weight, and the higher value is used for pricing.

- International Shipments: The formula changes to (Length x Width x Height) / 166 to accommodate different shipping requirements.

For example, a domestic package measuring 20 inches in length, 15 inches in width, and 10 inches in height would have a dimensional weight of approximately 21.6 pounds (20 x 15 x 10 / 139). If the package's actual weight is 18 pounds, UPS would charge based on the dimensional weight of 21.6 pounds.

Importance of Dimensional Weight for Shippers

Understanding dimensional weight is essential for businesses to manage shipping costs effectively. According to UPS, dimensional weight pricing helps optimize space utilization in delivery vehicles, leading to:

- Cost Efficiency: By accurately pricing shipments, carriers can offer competitive rates while ensuring they maximize vehicle capacity.

- Environmental Impact: Efficient space utilization reduces the number of trips needed, lowering fuel consumption and carbon emissions.

- Improved Planning: Shippers can make informed decisions about packaging sizes and materials to minimize shipping expenses.

By leveraging dimensional weight knowledge, businesses can streamline their logistics, enhance customer satisfaction, and maintain profitability.

Strategies to Reduce Dimensional Weight Costs

Minimizing dimensional weight can lead to significant savings. Here are effective strategies to reduce these costs:

- Optimize Packaging: Use appropriately sized boxes that snugly fit your products. Avoid over-packaging, which increases the package volume unnecessarily.

- Use Lightweight Materials: Select packing materials such as bubble wrap or air pillows instead of heavier fillers to reduce overall volume.

- Consolidate Shipments: Combine multiple items into a single package when possible to decrease the number of shipments and overall dimensional weight.

- Invest in Packaging Design: Custom packaging solutions tailored to your products can minimize empty space and enhance protection.

- Utilize UPS Tools: Use UPS’s Dimensional Weight Calculator to accurately estimate shipping costs before dispatching packages.

Common Mistakes to Avoid When Handling Dimensional Weight

Incorrectly managing dimensional weight can lead to unexpected shipping costs. Avoid these common pitfalls:

- Inaccurate Measurements: Ensure precise measurement of all three dimensions (length, width, height) and round up to the nearest inch as per UPS guidelines.

- Ignoring Packaging Weight: Include the weight of all packing materials when calculating the total weight of the package.

- Using Oversized Boxes: Avoid using larger boxes than necessary, which can inflate the dimensional weight without providing additional protection.

- Failing to Compare Carriers: Different carriers have varying dimensional weight calculations. Regularly compare UPS rates with other carriers like FedEx and USPS to ensure you're getting the best deal.

Comparing UPS Dimensional Weight with Other Carriers

Understanding how UPS's dimensional weight policies stack up against other major carriers can help you make informed shipping decisions:

- FedEx: Uses a similar formula to UPS but with a dimensional factor of 139 for both domestic and international shipments.

- USPS: Employs dimensional weight for Priority Mail and Parcel Select, using a divisor of 139, similar to UPS's domestic rate.

While the formulas might appear similar, the application and service offerings can vary, making it essential to review each carrier’s specific policies. Resources like the FedEx Rate Tools and USPS Priority Mail provide detailed insights into their dimensional weight calculations and shipping rates.

Measuring Your Package Correctly for Accurate Dimensional Weight

Accurate measurement is critical to ensure you're billed correctly. Follow these steps to measure your package:

- Measure Each Dimension: Use a measuring tape to determine the length, width, and height of the package in inches. Always measure the largest side.

- Calculate Volume: Multiply the length by the width by the height to obtain the package's volume.

- Determine Dimensional Weight: Divide the volume by the appropriate dimensional factor (139 for domestic, 166 for international shipments) to get the dimensional weight.

- Compare with Actual Weight: Use the higher value between actual and dimensional weight for billing.

Employing tools like digital scales and precise measuring equipment can enhance accuracy, reducing the likelihood of overcharges. Additionally, routine training for staff involved in packaging can ensure consistent and accurate measurements.

Conclusion: Optimizing Shipping Costs with UPS Dimensional Weight

Understanding and effectively managing UPS dimensional weight is pivotal for businesses aiming to control shipping expenses. By accurately measuring packages, optimizing packaging materials, and leveraging carrier tools, shippers can minimize costs and enhance operational efficiency. Staying informed about UPS’s policies and comparing them with other carriers ensures that your shipping strategy remains competitive and cost-effective.

For more detailed information, refer to the UPS Shipping Information and industry resources to stay updated on best practices and policy changes.