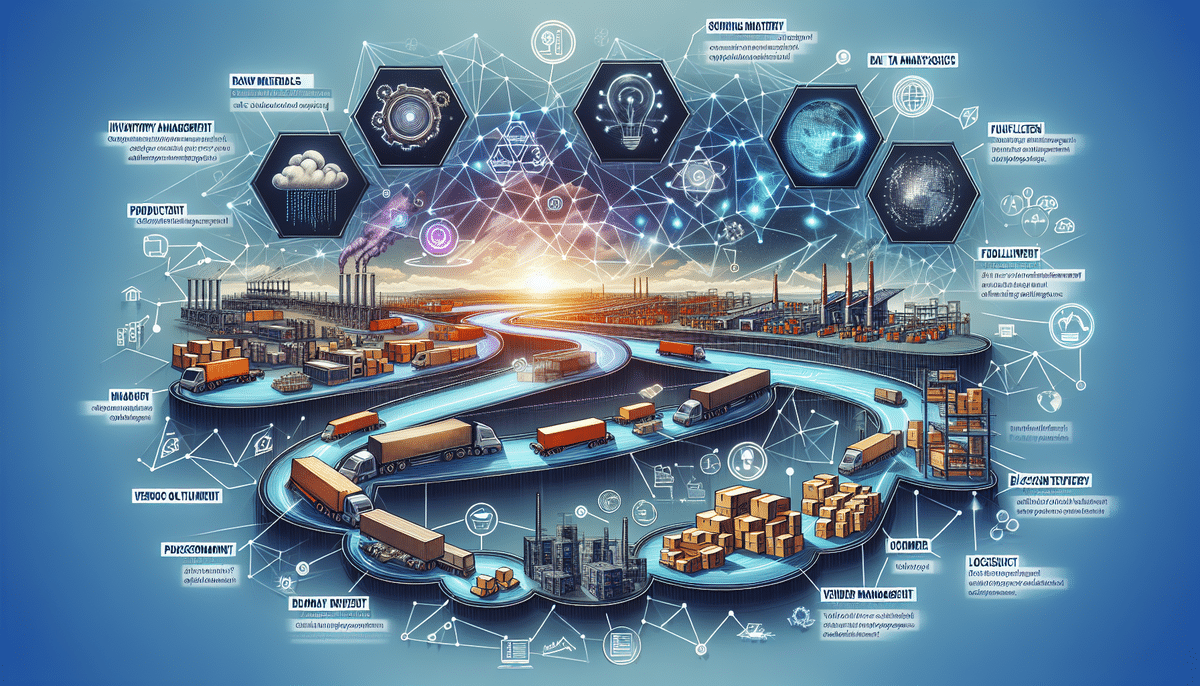

Overcoming E-Commerce Challenges: Streamlining Supply Chain Management

E-commerce has become a vital aspect of the retail industry, with the global online retail market expected to reach $6.54 trillion by 2023. However, managing an e-commerce supply chain can present significant challenges. In this article, we will explore the importance of supply chain management in e-commerce and examine strategies to overcome common obstacles.

The Importance of Supply Chain Management in E-Commerce

Supply chain management is essential for e-commerce businesses as it involves the planning and coordination of activities from the production to the delivery of goods to customers. An efficient supply chain ensures that products are available when and where customers need them, which is crucial for maintaining competitiveness in the fast-paced online market.

Enhancing Customer Satisfaction and Loyalty

Effective supply chain management leads to timely deliveries and high product quality, directly impacting customer satisfaction. According to a Forrester report, 77% of consumers have higher expectations for customer service in e-commerce. Meeting these expectations fosters loyalty and encourages repeat business.

Promoting Sustainability and Ethical Practices

Optimizing the supply chain can also contribute to sustainability by reducing waste and minimizing the carbon footprint. Implementing ethical sourcing practices not only benefits the environment but also enhances the brand's reputation, attracting environmentally conscious consumers.

Common Challenges in E-Commerce Supply Chain Management

Despite the benefits of having an efficient supply chain, e-commerce businesses face several challenges:

- Inventory Management: Balancing inventory levels to meet demand without overstocking requires precise forecasting and planning.

- Fulfillment: Ensuring timely and cost-effective shipping involves complex logistics coordination.

- Scalability: Adapting the supply chain to handle increased order volumes as the business grows.

- Vendor Management: Maintaining reliable relationships with multiple suppliers to ensure product quality and timely deliveries.

- Data Management: Handling large volumes of data related to orders, inventory, and shipments requires robust systems and expertise.

Strategies for Optimizing Supply Chain Efficiency

Implementing Technology Solutions

Adopting advanced technology can automate processes and enhance visibility across the supply chain. For instance, utilizing an integrated e-commerce platform can streamline order management, inventory tracking, and shipping operations from a centralized system.

Building Strong Vendor Relationships

Establishing and maintaining robust relationships with suppliers and logistics partners ensures reliability and flexibility. Regular communication and collaboration can help address potential issues proactively and improve overall supply chain performance.

Adopting Just-In-Time (JIT) Inventory Systems

JIT inventory systems minimize holding costs by ordering and receiving inventory only as needed. This approach reduces waste and ensures that inventory levels align closely with customer demand, enhancing efficiency and profitability.

Leveraging Advanced Technologies

Automation and Artificial Intelligence (AI)

Automation tools and AI can significantly enhance supply chain operations by predicting demand, optimizing inventory levels, and improving warehouse management. According to a McKinsey study, AI can improve supply chain forecasting accuracy by up to 50%.

Internet of Things (IoT)

IoT devices enable real-time monitoring of inventory and shipments, providing valuable data that can be used to optimize routes and reduce delays. This technology enhances transparency and allows businesses to respond swiftly to disruptions.

Blockchain Technology

Blockchain offers enhanced transparency and traceability in the supply chain, enabling businesses to track products from origin to delivery. This reduces the risk of counterfeit products and ensures compliance with quality standards.

Role of Data Analytics

Tracking Supplier Performance

Data analytics allows businesses to evaluate supplier performance based on metrics such as delivery times, defect rates, and compliance with standards. This information helps in making informed decisions and improving overall supply chain efficiency.

Enhancing Customer Satisfaction

By analyzing customer data, businesses can identify purchasing patterns and preferences, enabling them to tailor their offerings and improve the customer experience. Personalized services and targeted marketing strategies can lead to increased customer loyalty.

Collaborative Supply Chain Operations

Partnering with Suppliers and Logistics Providers

Collaboration with key partners facilitates better communication and coordination, reducing lead times and optimizing inventory levels. Utilizing supply chain management software can further enhance real-time information sharing and decision-making.

Developing a Robust Logistics Strategy

A comprehensive logistics strategy should address transportation, storage, and delivery in alignment with customer expectations. Factors such as shipping costs, delivery times, and packaging requirements must be carefully considered. Implementing regional warehouses can help reduce shipping times and costs, while technology solutions like transportation management systems can optimize routing and carrier selection.

Managing Inventory and Fulfillment

Effective inventory and fulfillment management are critical for ensuring on-time delivery and maintaining customer satisfaction. Utilizing inventory management software can provide real-time visibility into stock levels, automate reorder processes, and optimize warehouse layouts for efficient operations.

Mitigating Risks and Ensuring Resilience

To maintain resilience in the face of disruptions, businesses should develop comprehensive risk management strategies. This includes creating contingency plans for supply chain disruptions, diversifying suppliers to avoid dependency on a single source, and investing in cybersecurity measures to protect against cyber threats.

Best Practices for Sustainable and Ethical Supply Chain Operations

Sustainability and ethics are increasingly important to consumers. Businesses should implement sustainable practices such as reducing packaging waste, using eco-friendly transportation options, and ensuring fair labor practices within their supply chain. Certifications like Fair Trade or Organic can demonstrate a commitment to these values and enhance brand reputation.

Conclusion

Managing an e-commerce supply chain presents significant challenges, but with the right strategies and technologies, businesses can streamline operations to enhance efficiency, reduce costs, and improve customer satisfaction. By prioritizing sustainability and ethical practices, e-commerce businesses can not only achieve operational excellence but also build a strong, reputable brand that resonates with modern consumers.