A Complete Guide to Warehouse Management Systems in 2024

In today's fast-paced business landscape, efficient warehouse management is critical to the success of any organization. With the rapid advancement of technology, the role of a Warehouse Management System (WMS) has become increasingly pivotal. This guide provides an in-depth look at everything you need to know about Warehouse Management Systems in 2024.

Understanding the Basics of Warehouse Management Systems

A WMS is a software application that integrates all warehouse operations, from inventory management to order fulfillment. It provides warehouse managers with real-time visibility, enabling them to optimize every aspect of warehouse operations. By automating routine tasks, optimizing space utilization, and enhancing inventory accuracy, a WMS streamlines processes and boosts overall efficiency.

One of the key benefits of a WMS is its ability to provide detailed reporting and analytics. According to a 2023 Gartner report, companies using advanced WMS solutions have experienced a 20% increase in operational efficiency. This data-driven approach allows businesses to identify areas for improvement and make informed decisions to optimize warehouse operations. Additionally, a WMS can integrate with other systems, such as Transportation Management Systems (TMS), to offer end-to-end visibility and control over the entire supply chain.

The Evolution of Warehouse Management Systems

Historical Development

The concept of warehouse management is not new. However, the integration of technology to enhance warehouse processes has seen significant advancements over the decades. The first WMSs emerged in the 1980s, primarily focusing on inventory control. By the 1990s, features such as barcode scanning and automated data capture were introduced, marking a significant evolution in WMS capabilities.

Modern Innovations

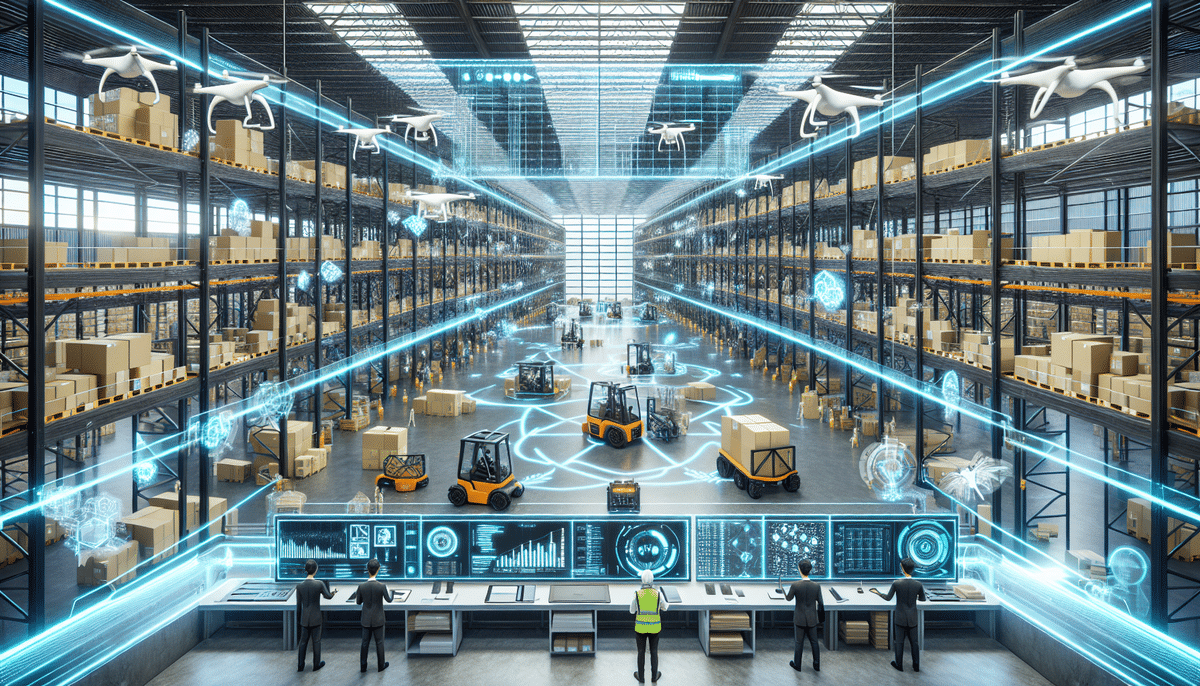

In recent years, advancements in technology have led to the development of highly sophisticated WMSs that incorporate artificial intelligence (AI), the Internet of Things (IoT), and cloud computing. Robotics has become a significant component, with Automated Guided Vehicles (AGVs) and drones being utilized to move products and perform inventory checks, thereby increasing efficiency and accuracy. Additionally, virtual and augmented reality technologies are being used for training warehouse employees and enhancing safety measures.

Another notable trend is the focus on sustainability. Many companies are implementing green initiatives within their warehouses, such as using renewable energy sources and reducing waste. Modern WMSs are equipped to track and analyze energy usage and carbon emissions, enabling businesses to make data-driven decisions to minimize their environmental impact.

Benefits of Implementing a Warehouse Management System

Enhanced Operational Efficiency

- Better Inventory Accuracy: Real-time tracking reduces discrepancies, ensuring inventory levels are accurate.

- Improved Productivity: Automation of routine tasks allows employees to focus on more strategic activities.

- Reduced Labor Costs: Optimized processes and efficient workflows decrease the need for manual labor.

- Optimized Space Utilization: Efficient layout planning maximizes storage capacity and reduces storage expenses.

- Faster Order Processing: Streamlined workflows lead to quicker order fulfillment and enhanced customer satisfaction.

Implementing a WMS provides real-time visibility into inventory levels, enabling warehouse managers to make informed decisions about reordering, stock replenishment, and inventory distribution. By eliminating manual data entry, a WMS reduces the likelihood of errors and enhances data accuracy. Additionally, optimized space utilization helps lower storage costs, contributing to overall profitability.

Improved Safety and Compliance

A WMS enhances safety within the warehouse by tracking the movement of goods and equipment, ensuring they are stored and transported securely. The system can provide alerts for potential safety hazards, such as unauthorized forklift operations in pedestrian areas. By improving safety protocols, businesses can reduce the risk of accidents and injuries, thereby avoiding costly lawsuits and protecting their reputation.

Furthermore, a WMS assists businesses in complying with regulatory requirements. It maintains accurate records of inventory levels, which are essential for audits and inspections. The system also helps ensure compliance with regulations related to product labeling, storage, and transportation, helping businesses avoid fines and maintain a positive standing with regulatory agencies.

Types of Warehouse Management Systems

On-Premise Systems

On-premise WMSs are installed and maintained on a company’s own servers, offering greater control and customization options. They are ideal for businesses that require high levels of data security and have the resources to manage and maintain the system internally. However, they come with higher upfront costs and ongoing maintenance expenses.

Cloud-Based Systems

Cloud-based WMSs are hosted on the vendor’s servers and accessed via the internet. They offer greater flexibility and scalability, allowing businesses to access the system from anywhere with an internet connection. These systems are typically offered on a subscription basis, making them a cost-effective option for businesses of all sizes.

Hybrid Systems

Hybrid systems combine elements of both on-premise and cloud-based systems, providing a balance between control and flexibility. They allow businesses to customize their solutions to meet specific needs while still benefiting from the scalability and accessibility of cloud-based systems.

When selecting a WMS, it’s crucial to consider the size of your business, the complexity of your operations, and your budget. Additionally, evaluate the level of support and training offered by the vendor, as well as the system’s ability to integrate with other software and hardware solutions.

Factors to Consider When Choosing a Warehouse Management System

- Business Size: Ensure the WMS can scale with your business growth.

- Operational Complexity: Assess if the WMS can handle the complexity of your warehouse operations.

- Number of Locations: Determine if the WMS supports multi-location management.

- Integration Requirements: Check if the WMS integrates seamlessly with your existing systems.

- Features and Functionalities: Identify the critical features you need, such as inventory management, order processing, and analytics.

Partnering with a vendor who understands your business needs, clearly communicates the capabilities of their system, and offers excellent customer support is essential. Additionally, consider the scalability of the system to accommodate future growth and the security features to protect sensitive data.

Implementing a Warehouse Management System

Implementing a WMS is a complex process that requires careful planning, preparation, and execution. The implementation typically involves several phases:

- Needs Assessment: Identify your business requirements and goals.

- System Design: Customize the WMS to fit your specific operations.

- Testing: Conduct thorough testing to ensure the system functions correctly.

- Training: Provide comprehensive training to your staff to ensure they can effectively use the WMS.

- Deployment: Implement the system and monitor its performance.

Engaging a professional team with experience in project management, system design, and implementation is crucial for a smooth deployment process. The team should work closely with your organization to address specific requirements and design a system tailored to your unique business needs.

Common Challenges and Solutions in Implementing a WMS

Resistance to Change

Employees may be hesitant to adopt new systems, fearing increased complexity or job displacement. To address this, communicate the benefits of the WMS clearly and involve employees in the implementation process to gain their buy-in and support.

Lack of Employee Buy-In

Without proper engagement, employees may not fully utilize the WMS. Ensuring that employees understand how the system will make their jobs easier and providing incentives for adoption can help mitigate this issue.

Inadequate Training

Insufficient training can lead to improper use of the system, resulting in decreased efficiency and increased errors. Providing comprehensive training programs ensures that all users are comfortable and proficient with the new system.

System Integration Issues

Integrating the WMS with existing systems can be complex and may cause disruptions if not handled properly. Working with experienced vendors and using standardized integration protocols can help streamline the process and minimize issues.

Implementing a structured change management strategy, providing effective communication, and ensuring seamless integration are key to overcoming these challenges and ensuring a successful WMS implementation.

Key Features to Look for in a Warehouse Management System

- Inventory Management: Real-time tracking and management of inventory levels.

- Order Management: Efficient processing and fulfillment of orders.

- Labor Management: Optimization of workforce productivity and scheduling.

- Reporting and Analytics: Comprehensive reports and data analysis tools.

- Integration Capabilities: Ability to integrate with other systems such as ERP, CRM, and TMS.

A well-designed WMS should align closely with your business processes and meet the specific needs of your organization. Evaluating these key features ensures that the system will effectively support your warehouse operations and drive efficiency.

Costs Involved in Implementing a Warehouse Management System

The costs of implementing a WMS vary based on several factors, including the type of system, the size of the business, and the project's scope. Typical costs include:

- Software Licensing: Fees for the WMS software.

- Hardware Deployment: Costs for necessary hardware such as servers and scanners.

- System Integration: Expenses related to integrating the WMS with existing systems.

- Employee Training: Costs for training staff to use the new system.

- Ongoing Maintenance and Support: Fees for system maintenance and technical support.

Despite the initial investment, the long-term benefits of a well-designed WMS—such as improved efficiency, accuracy, and profitability—typically outweigh the costs, making it a valuable investment for businesses looking to optimize their warehouse operations.

Best Practices for Maximizing Efficiency and Productivity with Your WMS

- Regularly Review and Update Processes: Continuously assess and refine warehouse processes to align with the capabilities of your WMS.

- Ensure Employee Buy-In and Engagement: Involve employees in the implementation process and encourage their feedback to foster a sense of ownership and commitment.

- Provide Adequate Training: Ensure all users are well-trained to utilize the WMS effectively, minimizing errors and maximizing productivity.

- Prioritize Inventory Accuracy: Implement procedures to maintain accurate inventory records, such as regular audits and cycle counts.

- Engage in Continuous Improvement: Regularly seek ways to enhance warehouse operations using the WMS, staying updated with the latest features and technologies.

Adhering to these best practices ensures that your WMS remains effective and continues to drive efficiency and productivity as your business evolves.

Real-Life Case Studies: Benefits of Implementing a WMS

- Distribution Company: Reduced its inventory cycle time by 70% while doubling handling capacity, leading to increased revenue and profitability.

- Retail Business: Achieved 99.99% inventory accuracy, saving time and money while significantly improving customer satisfaction.

- Manufacturing Firm: Streamlined order fulfillment processes, resulting in a 30% reduction in order processing time.

These examples demonstrate the transformative potential of a well-designed WMS in enhancing warehouse operations and driving business success.

Future Trends in Warehouse Management Systems

- Increased Use of Artificial Intelligence: AI-driven analytics and predictive maintenance will enhance decision-making and operational efficiency.

- Real-Time Analytics: Enhanced real-time data processing will provide better visibility and quicker responses to changes.

- Robotics and Automation: Greater integration of robotics and automated systems to handle repetitive tasks, reducing human error and increasing speed.

- Drones: Utilization of drones for inventory management and real-time monitoring will become more prevalent.

- Blockchain Integration: Enhancing supply chain traceability and security through blockchain technology will provide greater transparency and trust.

The rapid evolution of e-commerce and changing customer expectations present new opportunities for businesses to leverage technology in staying competitive and driving growth. Keeping abreast of these trends ensures that your WMS remains at the forefront of warehouse management innovation.

Conclusion

A Warehouse Management System is an essential tool for businesses aiming to optimize their warehouse operations and drive growth. By offering the right features and functionalities tailored to unique business needs, a well-designed WMS delivers numerous benefits, including improved efficiency, accuracy, speed, and profitability. As technology continues to advance, organizations must adapt to the changing landscape and leverage the latest tools to stay competitive. By following best practices, engaging professional support, and continuously refining processes, businesses can position themselves for long-term success in the ever-evolving world of warehouse management systems.