A Comprehensive Guide to Reverse Logistics

In today's competitive market, customer satisfaction is paramount. Businesses focus not only on delivering products to customers but also on efficiently managing returns. This is where reverse logistics becomes crucial. Reverse logistics involves the process of handling product returns, exchanges, repairs, and recycling. This comprehensive guide delves into the fundamentals of reverse logistics, its role in supply chain management, various processes involved, and the benefits, challenges, and best practices for optimizing operations.

Understanding the Basics of Reverse Logistics

Reverse logistics encompasses all activities related to the flow of goods after they have reached the end consumer. Whether products are returned due to defects, excess inventory, or end-of-life, reverse logistics involves the transportation, storage, and proper disposition of these items. Effective management of reverse logistics helps businesses minimize the financial impact of returns and maintain high levels of customer satisfaction.

One of the primary challenges in reverse logistics is tracking returned products throughout the supply chain. Implementing technologies such as RFID tagging and automated sorting systems can significantly enhance visibility and efficiency in handling returns.

Cost management is another critical aspect of reverse logistics. Expenses related to shipping, restocking, refurbishing, and disposing of returned items can accumulate quickly. Establishing clear return policies and maintaining effective communication with customers are essential strategies to streamline the returns process and reduce associated costs.

The Importance of Reverse Logistics in Supply Chain Management

Reverse logistics plays a vital role in modern supply chain management by contributing to sustainability, cost reduction, and enhanced customer relations. By efficiently managing returns and recycling processes, businesses can recover value from returned products and minimize environmental impact. According to a Deloitte report, effective reverse logistics can lead to a 20% reduction in overall supply chain costs.

Enhancing customer satisfaction is another significant benefit of reverse logistics. A seamless returns process builds trust and loyalty, encouraging repeat purchases and positive word-of-mouth. For instance, research from the Bain & Company highlights that 70% of customers are more likely to return to a retailer that offers a hassle-free returns policy.

Types of Reverse Logistics Processes

Reverse logistics can be categorized into several key processes:

- Returns Management: Handling returned items from customers for exchange, repair, or refund.

- Remanufacturing: Refurbishing used or defective products to meet quality standards.

- Recycling: Disassembling products to recover materials for reuse.

- Asset Recovery: Extracting remaining value from used or unwanted products.

- Warranty Management: Processing warranty claims for defective products.

- Disposition: Deciding the optimal disposal method for products that cannot be resold or recycled.

Implementing these reverse logistics processes helps businesses reduce waste, recover value, and comply with environmental regulations. According to the Council of Supply Chain Management Professionals (CSCMP), companies that effectively manage reverse logistics can achieve significant cost savings and enhance their sustainability efforts.

Benefits of Implementing a Reverse Logistics System

Adopting a robust reverse logistics system offers a multitude of benefits:

- Reduced disposal and obsolescence costs

- Increased efficiency in material and inventory flow

- Enhanced customer satisfaction and loyalty

- New revenue streams from remanufactured or recycled products

- Improved sustainability and reduced environmental footprint

Additionally, effective reverse logistics allows businesses to recover lost or damaged products, saving costs and ensuring customers receive the products they ordered. A study by McKinsey & Company indicates that optimizing reverse logistics processes can lead to a 10-15% increase in overall operational efficiency.

Moreover, adherence to environmental regulations through proper disposal and recycling practices helps businesses avoid fines and enhances their reputation as environmentally responsible organizations.

Challenges and Solutions in Managing Reverse Logistics

Managing reverse logistics presents several challenges, including limited visibility, complex return processes, and high processing costs. To address these issues, businesses can implement the following solutions:

- Adopt advanced tracking technologies to monitor returns effectively

- Collaborate with logistics partners to enhance supply chain visibility

- Optimize inventory management and product design to minimize return rates

Environmental impact is another significant challenge. The transportation and processing of returned products can contribute to carbon emissions and waste. To mitigate this, businesses should adopt sustainable practices such as recycling, refurbishing, and using eco-friendly packaging materials. Partnering with logistics providers that prioritize sustainability can further reduce the environmental footprint of reverse logistics operations.

Key Metrics to Measure the Success of Reverse Logistics

Evaluating the effectiveness of reverse logistics is essential for continuous improvement. Key metrics include:

- Percentage of Returned Goods Resold or Remanufactured: Measures the efficiency of value recovery from returns.

- Percentage of Goods Recovered or Recycled: Assesses sustainability efforts and waste reduction.

- Return Cycle Time: Tracks the duration taken to process a return.

- Return Rate: The proportion of products returned relative to total sales.

- Cost per Return: Calculates the expenses involved in processing each return.

Understanding the reasons for returns is also critical. Analyzing return reasons helps identify product defects, quality issues, or mismatches between customer expectations and product offerings. Implementing changes based on this analysis can lead to a reduction in future return rates.

Furthermore, assessing the environmental impact by tracking waste generated and the percentage of products recycled or donated provides insights into the sustainability of reverse logistics practices.

Best Practices for Effective Reverse Logistics Operations

To optimize reverse logistics, businesses should adopt the following best practices:

- Collaborate with logistics providers and partners to enhance visibility and streamline material flow

- Establish a system for tracking, analyzing, and optimizing returns data

- Invest in technology to automate processes, reducing processing time and costs

- Design products with an emphasis on quality, durability, and ease of repair

- Implement sustainability initiatives to improve performance and minimize environmental impact

Effective communication with customers is also essential. Providing clear return instructions, offering multiple return options, and responding promptly to customer inquiries improve the overall returns experience. This not only enhances customer satisfaction but also reduces the likelihood of return-related issues and negative reviews.

Case Studies: Successful Implementation of Reverse Logistics Strategies

Several companies have effectively implemented reverse logistics strategies to enhance efficiency and customer satisfaction:

- Apple's Recycling Program allows customers to return used devices for proper disposal and recycling, promoting sustainability and resource recovery.

- Dell has streamlined its returns management process, leading to decreased return rates and increased profits from remanufactured products.

- Nike's Reuse-A-Shoe Program collects old athletic shoes and recycles them into materials for sports surfaces and equipment, reducing waste and supporting environmental initiatives.

- Walmart has implemented a reverse logistics strategy that consolidates returned products from its stores and redistributes them to other locations or sells them through online marketplaces, resulting in significant cost savings and waste reduction.

Future Trends and Innovations in Reverse Logistics

The landscape of reverse logistics is evolving with advancements in technology and changing consumer expectations. Emerging trends and innovations include:

- Artificial Intelligence and Machine Learning: Utilizing predictive analytics and automation to enhance the tracking and processing of returns.

- Circular Economy Models: Focusing on the reuse and recycling of products to extend their lifecycle and reduce waste.

- Blockchain Technology: Providing increased transparency and traceability within the supply chain, ensuring the authenticity and proper handling of returned products.

- Sustainable Practices and Materials: Emphasizing eco-friendly operations and the use of sustainable materials in packaging and product design.

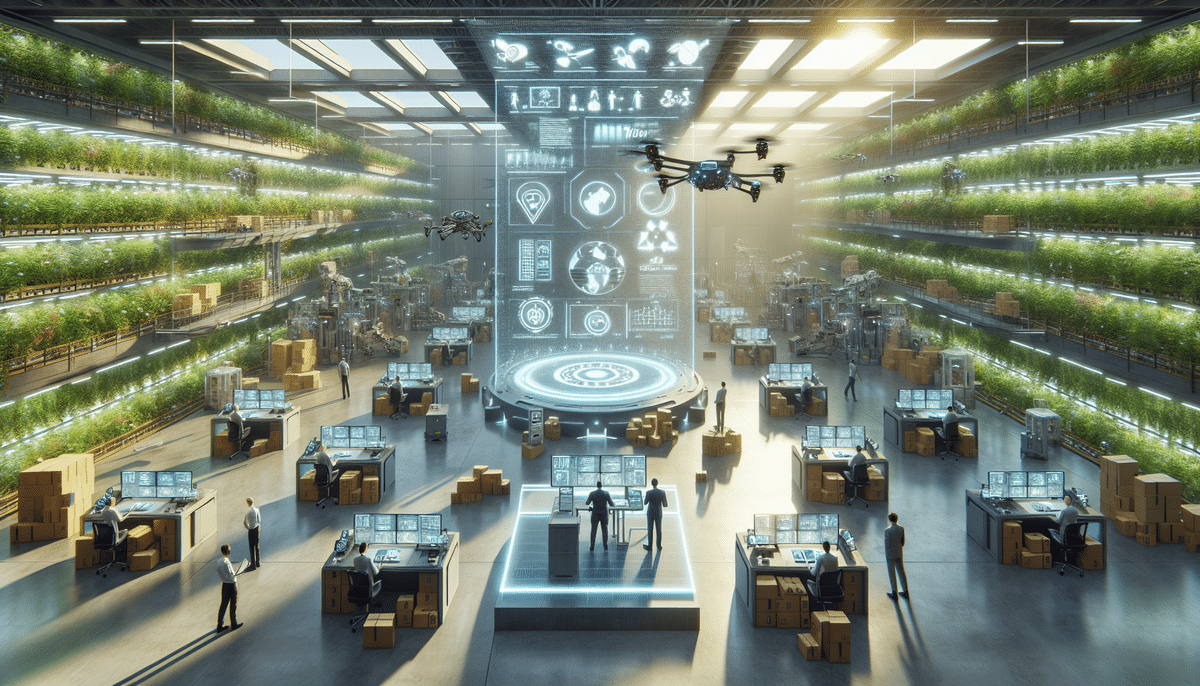

Automation and robotics are set to revolutionize reverse logistics by speeding up the processing of returns and reducing human error. Companies are increasingly adopting automated sorting systems and using robots for handling and packaging returned items. Additionally, the integration of drones and autonomous vehicles for the transportation of returns is being explored to enhance efficiency and reduce costs.

The adoption of circular economy principles is also gaining momentum, with businesses striving to create closed-loop systems where products are continuously reused, refurbished, and recycled. This not only supports sustainability but also opens up new revenue streams and reduces dependency on raw materials.

In conclusion, reverse logistics is an essential component of supply chain management that offers significant benefits, including cost savings, enhanced customer satisfaction, and improved sustainability. By implementing best practices, leveraging advanced technologies, and staying informed about emerging trends, businesses can effectively manage reverse logistics and achieve long-term success.