Introduction to Cold Chain 3PL Logistics Fulfillment

In today’s global marketplace, efficient logistics are paramount, especially for products that are temperature-sensitive. Third-party logistics (3PL) providers play a crucial role in managing the storage, transportation, and delivery of these goods. Cold Chain 3PL Logistics Fulfillment specializes in maintaining the integrity of products that require specific temperature conditions throughout the supply chain, such as pharmaceuticals, biologics, and perishable food items.

Importance in the Pharmaceutical Industry

The pharmaceutical industry heavily relies on cold chain logistics to ensure the efficacy and safety of medications and vaccines. According to a report by the World Health Organization, maintaining the correct temperature is critical for preserving the stability and effectiveness of many life-saving drugs. Failure to adhere to these conditions can lead to reduced potency, increased risks of contamination, and ultimately, compromised patient safety.

Regulatory Compliance

Cold chain 3PL providers help pharmaceutical companies comply with stringent regulations imposed by bodies such as the FDA and the EMA. These regulations mandate precise temperature monitoring and documentation to ensure that products remain within specified temperature ranges from production to delivery.

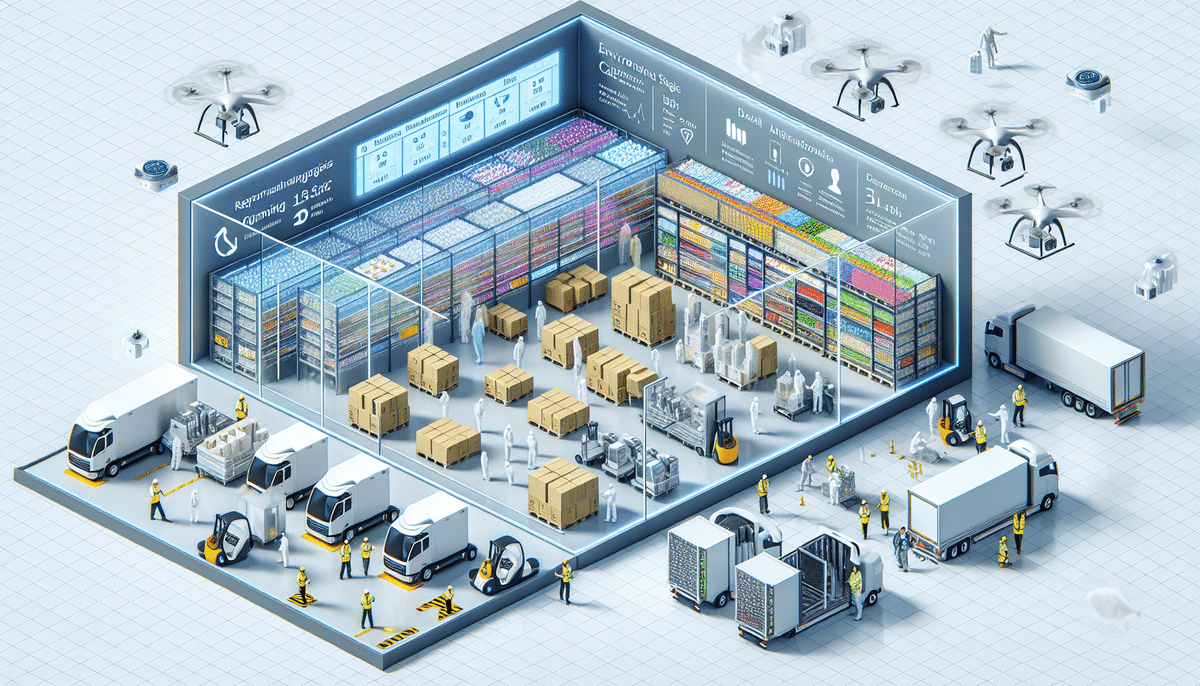

How Cold Chain 3PL Logistics Fulfillment Works

The cold chain logistics process involves a series of coordinated steps to maintain temperature-controlled environments for sensitive products:

- Product Storage: Items are stored in temperature-controlled warehouses equipped with refrigeration or freezing systems to maintain required conditions.

- Transportation: Specialized vehicles with temperature regulation capabilities transport products, ensuring consistent temperature control throughout transit.

- Temperature Monitoring: Advanced sensors and real-time tracking systems continuously monitor the temperature during storage and transportation, providing alerts if deviations occur.

- Quality Control: Rigorous inspections and testing are conducted to verify that products maintain their integrity and quality during the entire supply chain process.

Value-Added Services

Cold chain 3PL providers often offer additional services such as kitting, labeling, and customized packaging solutions. These services enhance supply chain efficiency and ensure that products are handled according to specific client requirements.

Benefits and Challenges of Cold Chain 3PL Logistics Fulfillment

Benefits

- Enhanced Product Quality: Maintaining appropriate temperatures preserves the efficacy and safety of temperature-sensitive products.

- Reduced Waste: Proper temperature control minimizes spoilage and extends the shelf life of perishable goods, leading to significant cost savings.

- Regulatory Compliance: Ensures adherence to industry standards and regulations, avoiding legal penalties and enhancing market reputation.

- Expanded Market Reach: Enables businesses to distribute products to remote or geographically dispersed markets without compromising quality.

Challenges

- High Operational Costs: Investing in specialized equipment and technology required for cold chain logistics can be expensive.

- Complexity of Management: Coordinating multiple stages of the supply chain to maintain temperature control demands meticulous planning and execution.

- Risk of Equipment Failure: Malfunctions in refrigeration units or transportation vehicles can lead to temperature excursions, resulting in product loss and financial repercussions.

To address these challenges, companies must implement robust contingency plans, invest in reliable technology, and maintain regular equipment maintenance schedules.

The Role of Technology in Cold Chain 3PL Logistics Fulfillment

Advancements in technology have revolutionized cold chain logistics, providing unprecedented levels of control and visibility:

- Internet of Things (IoT): IoT-enabled devices allow for real-time tracking and monitoring of temperature-sensitive products, ensuring immediate detection of any deviations.

- Blockchain Technology: Blockchain enhances transparency and traceability within the supply chain, providing immutable records of temperature data and product movement.

- Automated Inventory Management: Systems utilizing barcodes and RFID tags streamline inventory processes, reducing errors and improving efficiency.

- Predictive Analytics: Machine learning algorithms analyze data patterns to forecast potential issues, enabling proactive measures to prevent disruptions.

According to a report by Gartner, the integration of IoT and blockchain technologies is expected to continue driving innovation and efficiency in cold chain logistics.

Best Practices for Managing Cold Chain 3PL Logistics Fulfillment

- Invest in Specialized Equipment: Utilize state-of-the-art refrigeration and transportation equipment to maintain consistent temperature control.

- Partner with Experienced Providers: Collaborate with 3PL providers that have proven expertise and robust infrastructure for handling temperature-sensitive products.

- Implement Real-Time Monitoring: Deploy advanced monitoring systems to track temperatures continuously and receive instant alerts in case of deviations.

- Develop Comprehensive Contingency Plans: Prepare for potential disruptions by establishing protocols for equipment failures, power outages, and other unforeseen events.

- Regular Training and Communication: Ensure that all stakeholders are adequately trained and maintain open lines of communication to address issues promptly.

- Maintain Compliance with Regulations: Stay updated with the latest regulatory requirements and ensure all processes adhere to necessary standards.

Future Trends and Outlook for Cold Chain 3PL Logistics Fulfillment

The cold chain 3PL logistics sector is poised for significant growth, driven by increasing demand for temperature-controlled products and advancements in technology. Key trends shaping the future include:

- Increased Adoption of Sustainable Practices: There's a growing emphasis on eco-friendly refrigeration solutions and energy-efficient transportation methods to reduce the environmental impact of cold chain logistics.

- Enhanced Last-Mile Delivery Solutions: Innovations such as autonomous vehicles and drone deliveries are being explored to improve the efficiency and reliability of last-mile logistics for temperature-sensitive products.

- Integration of Advanced Analytics: The use of big data and artificial intelligence will enable more precise forecasting, inventory management, and operational optimization.

- Expansion of Global Supply Chains: As global trade continues to grow, cold chain logistics will expand to accommodate the increasing complexity and scale of international supply chains.

According to MarketsandMarkets, the global cold chain logistics market is projected to reach USD 522.8 billion by 2027, reflecting a compound annual growth rate (CAGR) of 7.4% from 2022.

Choosing the Right Provider for Cold Chain 3PL Logistics Fulfillment

Selecting an appropriate cold chain 3PL provider is critical for maintaining the quality and safety of temperature-sensitive products. Consider the following factors when making your choice:

- Experience and Expertise: Evaluate the provider’s track record in handling products similar to yours, whether they are pharmaceuticals, food items, or other temperature-sensitive goods.

- Infrastructure and Technology: Ensure the provider has advanced temperature control systems, real-time monitoring capabilities, and robust IT infrastructure to support efficient logistics operations.

- Quality Control and Compliance: Assess the provider’s quality assurance processes and their ability to comply with relevant industry regulations and standards.

- Customer Feedback and Reputation: Research client testimonials, reviews, and case studies to gauge the provider’s reliability and customer satisfaction levels.

- Geographical Reach: Consider the provider’s ability to service your target markets, including their network coverage and distribution capabilities.

Additionally, it is beneficial to choose a provider that offers customizable solutions tailored to your specific needs and can scale operations as your business grows.

In conclusion, Cold Chain 3PL Logistics Fulfillment is indispensable for businesses dealing with temperature-sensitive products. By leveraging specialized expertise, advanced technology, and adhering to best practices, companies can ensure the safe and efficient delivery of their products, expand their market reach, and maintain compliance with regulatory standards.

Key Players in the Cold Chain 3PL Logistics Fulfillment Market

The cold chain logistics market is highly competitive, with several major players leading the industry:

- AmerisourceBergen: A global leader in pharmaceutical sourcing and distribution, providing comprehensive cold chain logistics solutions.

- DHL: Offers extensive cold chain services, including temperature-controlled warehousing and specialized transportation.

- UPS: Provides reliable cold chain logistics through its UPS Temperature True® service, ensuring temperature-sensitive shipments remain within specified ranges.

- FedEx: Features FedEx Cold Shipping® services designed to handle perishable and temperature-sensitive products efficiently.

- Kuehne+Nagel: Delivers tailored cold chain logistics solutions with a focus on pharmaceuticals, life sciences, and food sectors.

These companies continuously invest in technology and infrastructure to enhance their cold chain capabilities, meeting the evolving demands of global markets and ensuring the integrity of temperature-sensitive products.