A Day in the Life of a Warehouse Picker: What It's Really Like

Working in a warehouse as a picker is a demanding role that requires precision, physical stamina, and keen attention to detail. From fulfilling customer orders to managing inventory and maintaining a safe working environment, this position encompasses a variety of responsibilities. In this article, we delve into the daily duties and responsibilities of a warehouse picker, the essential skills and qualifications needed, safety measures, technological advancements, and more.

The Role of a Warehouse Picker: Duties and Responsibilities

As a warehouse picker, your primary duty is to accurately pick, pack, and ship products to meet customer demands. This involves:

- Selecting the correct items from inventory using order lists

- Packing products securely to prevent damage during transit

- Ensuring timely shipment of orders

- Managing inventory levels and restocking shelves as needed

- Collaborating with other warehouse staff to streamline operations

- Adhering to company protocols and supervisor assignments

Efficient order fulfillment not only enhances customer satisfaction but also contributes to the overall success of the business.

Required Skills and Qualifications for a Warehouse Picker

The role of a warehouse picker demands a combination of physical and cognitive skills, including:

- Physical Strength and Endurance: Ability to stand, walk, and lift heavy items for extended periods.

- Attention to Detail: Ensuring accuracy in selecting and packing orders.

- Communication Skills: Coordinating with team members for efficient operations.

- Basic Computer Skills: Utilizing inventory management software and handheld devices.

- Forklift Operation: Certification may be required for operating warehouse machinery.

Educational requirements typically include a high school diploma or equivalent, with prior warehouse experience being preferred by many employers.

According to the U.S. Bureau of Labor Statistics, the median hourly wage for order fillers was $14.53 in May 2020, with job prospects remaining strong as e-commerce continues to grow.

The Importance of Safety in the Warehouse Environment

Maintaining a safe work environment is paramount in any warehouse setting. As a picker, you must be vigilant about potential hazards and adhere to safety protocols to prevent accidents. Key safety practices include:

- Wearing appropriate protective gear, such as gloves and steel-toed boots

- Following established safety procedures and guidelines

- Keeping the warehouse organized to prevent slips, trips, and falls

- Properly handling and operating heavy machinery like forklifts and conveyor belts

- Reporting any safety concerns or hazards to supervisors immediately

Adhering to these safety measures not only protects employees but also safeguards the integrity of products and equipment, ultimately reducing operational costs and enhancing customer satisfaction.

Statistics show that OSHA reports a significant number of workplace injuries occur in warehouse environments, highlighting the critical need for comprehensive safety training and protocols.

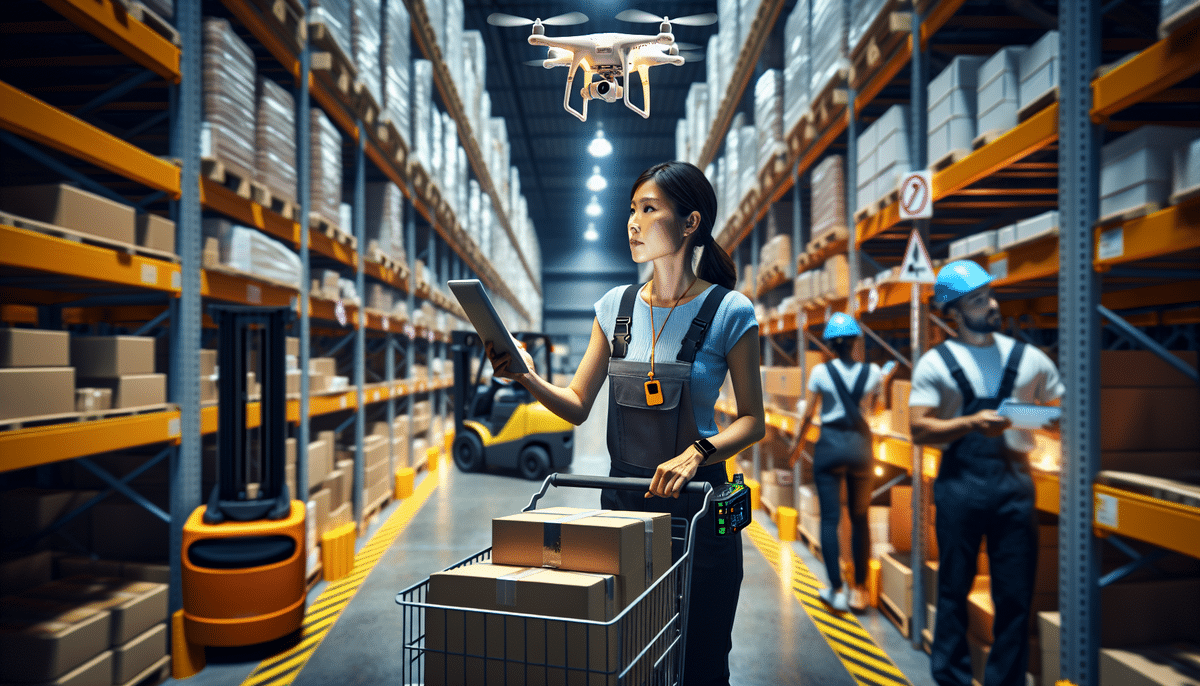

How Technology is Revolutionizing Warehouse Picking Processes

Advancements in technology have significantly transformed warehouse operations, enhancing efficiency and accuracy in the picking process. Modern warehouses utilize a variety of technological tools, including:

- Automated Picking Systems: Robotics and automated machinery streamline the selection and packaging of products.

- Inventory Management Software: Enhances real-time tracking and management of stock levels.

- Barcode and RFID Scanning: Improves accuracy in order fulfillment and inventory tracking.

- Drones: Used for inventory scanning and transporting items within the warehouse, reducing human error and increasing speed.

These technological innovations not only boost productivity but also reduce the reliance on manual labor, allowing warehouses to handle increasing order volumes with greater precision.

A recent report by McKinsey & Company highlights that automation can increase warehouse productivity by up to 40%, while also significantly reducing operational costs.

The Impact of COVID-19 on Warehouse Operations and Safety Protocols

The COVID-19 pandemic has markedly impacted warehouse operations, necessitating enhanced safety measures and adaptations to meet surging demand for essential goods. Key changes implemented include:

- Staggered shifts to minimize employee interactions and ensure social distancing

- Increased sanitization of workspaces and equipment

- Introduction of contactless delivery and pickup options

- Provision of hazard pay and incentives to frontline workers

Despite these measures, the pandemic has introduced challenges such as supply chain disruptions and staffing shortages. In response, many warehouses are accelerating the adoption of automation and robotics to mitigate the impact of future disruptions and maintain operational continuity.

According to a Forbes article, the demand for automated solutions in warehouses surged by over 50% during the pandemic, underscoring the critical role of technology in resilient supply chain management.

A Guide to Efficient Picking Techniques for Maximum Productivity

Maximizing productivity as a warehouse picker involves implementing effective picking strategies and maintaining an organized workflow. Here are some techniques to enhance efficiency:

- Zone Picking: Dividing the warehouse into specific zones and assigning pickers to these areas reduces travel time and increases focus on specific product categories.

- Batch Picking: Collecting multiple orders simultaneously allows for bulk processing, saving time and reducing repetitive movements.

- Wave Picking: Coordinating picking activities in waves based on order patterns and inventory levels ensures a balanced workflow.

- Proper Training: Ensuring pickers are well-trained in using equipment and following protocols enhances speed and accuracy.

- Utilizing Technology: Implementing handheld devices and inventory management systems can streamline the picking process.

By adopting these strategies, warehouse pickers can significantly boost their productivity, contributing to the overall efficiency and success of the warehouse operations.

The Physical Demands of the Job: Challenges and Solutions for Warehouse Pickers

Warehouse picking is a physically demanding job that involves lifting, moving, and transporting heavy items, often requiring sustained physical effort. Common challenges include:

- Musculoskeletal Strain: Repetitive motions and heavy lifting can lead to muscle fatigue and injuries.

- Fatigue: Long hours on foot can result in exhaustion and decreased performance.

- Repetitive Stress Injuries: Continuous repetitive tasks increase the risk of chronic injuries.

To address these challenges, both employees and employers can take proactive measures:

- Ergonomic Equipment: Utilizing equipment like forklifts and conveyor belts reduces the physical strain on workers.

- Regular Breaks: Implementing scheduled breaks helps prevent fatigue and allows workers to recover.

- Team Lifting: Encouraging collaborative lifting of heavy items distributes the workload and minimizes injury risks.

- Physical Conditioning: Workers can engage in regular exercise and stretching to build strength and flexibility.

- Comprehensive Training: Educating workers on proper lifting techniques and safety protocols reduces the likelihood of injury.

By addressing the physical demands of the job through these solutions, warehouse pickers can maintain their health and sustain long-term productivity.

Salary Expectations and Job Outlook for Warehouse Pickers

The compensation for warehouse pickers varies based on factors such as location, experience, and the specific employer. As of May 2020, the Bureau of Labor Statistics reported a median hourly wage of $14.53 for order fillers, with potential for higher earnings in specialized or higher-demand roles.

The job outlook for warehouse pickers remains positive, driven by the growth of e-commerce and the increasing need for efficient fulfillment centers. Employment in this sector is projected to grow 4% from 2020 to 2030, adding approximately 100,000 new jobs in the United States alone.

Despite the physical demands, many employers offer competitive benefits, opportunities for advancement, and training programs to enhance skills. Careers in warehousing can be both stable and rewarding for individuals who thrive in fast-paced environments and possess the necessary physical and cognitive abilities.

From Entry-Level to Management: Career Progression in the Warehousing Industry

The warehousing industry provides numerous opportunities for career advancement, allowing workers to progress from entry-level positions to supervisory and managerial roles. Potential career paths include:

- Supervisory Roles: Overseeing teams of pickers and ensuring efficient daily operations.

- Inventory Management: Managing stock levels, conducting audits, and optimizing inventory processes.

- Logistics Coordination: Planning and coordinating the movement of goods within and outside the warehouse.

- Quality Assurance: Ensuring products meet quality standards and handling returns or defects.

Many companies offer on-the-job training and opportunities for certification, enabling employees to acquire new skills and advance their careers. Additionally, the potential for geographic mobility allows workers to pursue opportunities in different locations, further enhancing their career prospects.

A study by Forbes indicates that career progression within warehousing not only increases earning potential but also provides pathways to diverse roles in supply chain and logistics management.

A Day in the Life of a Seasonal Warehouse Picker: Holiday Rush Edition

Seasonal warehouse picking during the holiday season presents unique challenges and opportunities. Responsibilities during this peak period include:

- Handling a significantly higher volume of orders

- Ensuring timely and accurate delivery to meet consumer demand

- Adapting to accelerated workflows and extended shifts

- Collaborating closely with team members to maintain efficiency

Seasonal pickers must be adaptable, resilient, and ready to work in a fast-paced environment. Effective time management and stress management techniques are essential to handle the increased workload and maintain high performance.

Employers often provide additional incentives, such as performance bonuses and temporary benefits, to attract and retain seasonal workers during the holiday rush.

Common Misconceptions About Working as a Warehouse Picker Debunked

There are several misconceptions about the role of a warehouse picker that can deter potential candidates. Let's address and debunk some of these myths:

- Low-Skill Job: Contrary to the belief that it's an entry-level position requiring minimal skills, warehouse picking demands attention to detail, organizational abilities, and proficiency with technology.

- Unsafe Environment: While warehouses do have inherent risks, adherence to safety protocols and proper training significantly mitigate these hazards, making it a safe workplace.

- Limited Career Growth: The warehousing industry offers clear paths for advancement, including supervisory and specialized roles that provide opportunities for professional development.

- Monotonous Work: Modern warehouses utilize technology and varied tasks to keep the work dynamic and engaging.

Understanding the true nature of warehouse picking reveals it as a vital, rewarding, and growth-oriented career choice within the logistics and supply chain industry.

Conclusion

Being a warehouse picker is a multifaceted role that combines physical labor with strategic responsibilities such as order fulfillment, inventory management, and safety compliance. By understanding the demands and embracing opportunities for growth, warehouse pickers play a crucial role in the success of logistics operations and can build a rewarding career in this dynamic industry.