A Technical Product Overview of GreyOrange Warehouse Automation Software for E-Commerce Shippers

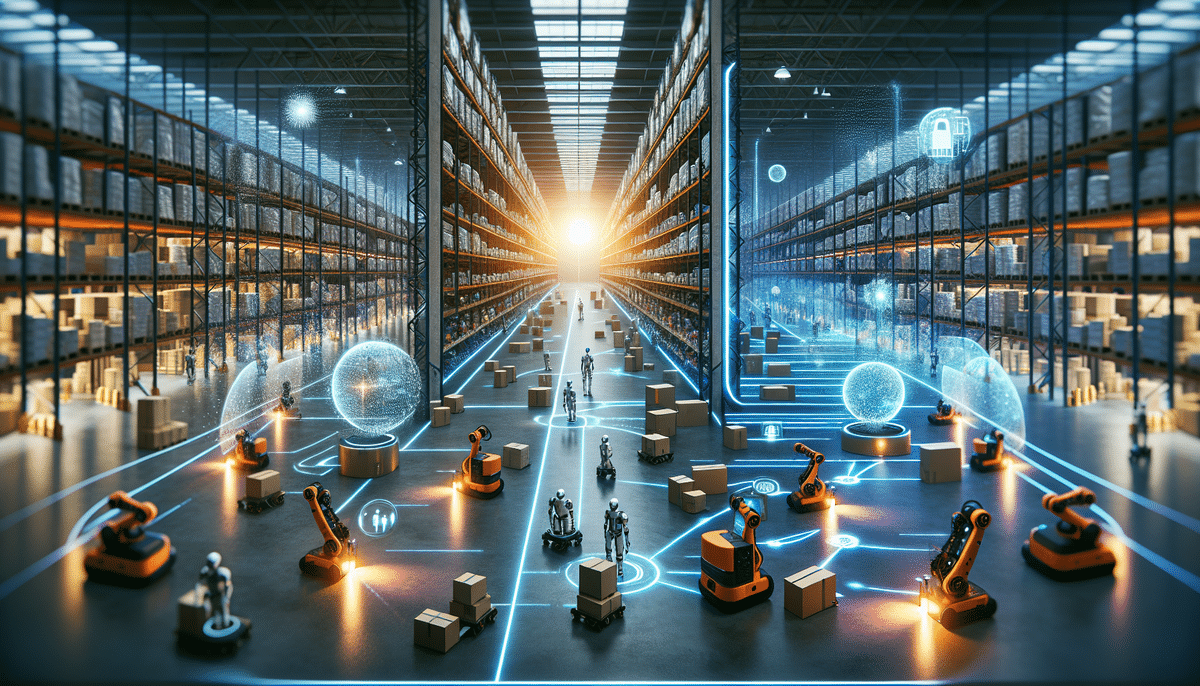

E-commerce shippers constantly seek tools that streamline warehouse management processes while keeping costs in check. GreyOrange Warehouse Automation Software offers a comprehensive solution to this challenge. This article provides a detailed technical overview of GreyOrange's warehouse automation software, highlighting key features, benefits, and how it enhances order accuracy and efficiency using Artificial Intelligence (AI).

Key Features of GreyOrange Warehouse Automation Software

GreyOrange's warehouse automation software is equipped with several advanced features designed to optimize e-commerce warehouse operations. These include:

- Autonomous Mobile Robots (AMRs): These robots handle tasks such as picking, sorting, and transporting goods, reducing the need for manual labor.

- GreyMatter AI: An intelligent engine that powers the robots, enabling real-time data analysis and decision-making to optimize warehouse workflows.

- GreyOrange Flexo: A modular sortation system that allows for scalable and flexible sorting processes, accommodating varying order volumes.

- GreyOrange Butler: An advanced goods-to-person technology that streamlines the order fulfillment process by reducing pick times and improving accuracy.

Benefits of Using GreyOrange Warehouse Automation Software for E-Commerce Shippers

Implementing GreyOrange's software offers numerous benefits to e-commerce shippers, including:

- Cost Reduction: Autonomous mobile robots enable handling higher order volumes without increasing staff, significantly reducing labor costs.

- Increased Efficiency: Automation of tasks such as receiving, put-away, picking, and shipping accelerates warehouse operations, leading to faster order fulfillment.

- Improved Accuracy: AI-driven systems minimize human errors, ensuring order accuracy and enhancing customer satisfaction.

- Real-Time Analytics: Access to real-time data on inventory levels, order volumes, and operational metrics allows for informed decision-making and continuous optimization.

According to a McKinsey & Company report, implementing AI-driven warehouse automation can increase operational efficiency by up to 25% while reducing labor costs by approximately 20%.

Enhancing Order Accuracy and Efficiency with Artificial Intelligence (AI)

Artificial Intelligence plays a pivotal role in GreyOrange's warehouse automation software. The AI algorithms enable:

- Demand Forecasting: Predicting order trends and adjusting inventory levels proactively to meet customer demands efficiently.

- Route Optimization: Calculating the most efficient paths for robots to pick and place items, minimizing pick time and travel distance.

- Quality Control: Using machine learning to identify defects in products and packaging, ensuring only high-quality items reach customers.

- Warehouse Layout Optimization: Analyzing product demand and order frequency to suggest the most efficient warehouse layout, enhancing picking and packing processes.

These AI-driven capabilities not only enhance accuracy but also enable warehouses to handle a higher volume of orders with greater efficiency. For more insights on AI in warehouse operations, visit this Forbes article.

Successful Implementations: Case Studies of GreyOrange Warehouse Automation Software

GreyOrange's warehouse automation software has been successfully implemented by numerous e-commerce shippers globally, resulting in significant operational improvements:

- Global Source Logistics: An Australian courier company deployed GreyOrange's Butler system, leading to a 50% increase in order fulfillment rates and a 30% reduction in pick times.

- Nitori: A leading Japanese home goods retailer integrated GreyOrange's robots and automated storage system, enhancing order fulfillment processes while lowering labor costs.

Additionally, a major US-based e-commerce company reported a 70% reduction in labor costs and a 50% increase in order accuracy after adopting GreyOrange's system. A European retailer experienced a 40% increase in productivity and a 25% reduction in inventory holding costs, showcasing the versatility and effectiveness of GreyOrange's automation solutions. For more detailed case studies, visit the GreyOrange Case Studies page.

Comparing GreyOrange Warehouse Automation Software to Other Solutions

While numerous warehouse management solutions exist, GreyOrange distinguishes itself through:

- Flexibility and Scalability: GreyOrange's software easily integrates with existing warehouse systems and can be customized to fit various layouts, allowing businesses to scale operations as needed.

- Advanced Robotics: The intelligent AMRs operate autonomously with minimal supervision, enhancing operational efficiency compared to less autonomous competitors.

- Comprehensive Analytics: Real-time data and analytics provide deep insights into warehouse operations, enabling businesses to optimize processes based on actionable data.

- Holistic Approach: GreyOrange combines both software and hardware solutions, offering a unified system for managing all aspects of warehouse operations.

According to a Gartner report, the warehouse automation market is rapidly evolving, and solutions that offer integration flexibility and scalability, like GreyOrange, are better positioned to meet diverse business needs.

Assessing the Return on Investment (ROI) for Implementing GreyOrange

Implementing GreyOrange's warehouse automation software can lead to substantial ROI through:

- Reduced Labor Costs: Automation reduces the need for manual labor, leading to significant cost savings.

- Increased Productivity: Enhanced operational efficiency allows businesses to handle more orders without proportional increases in costs.

- Improved Accuracy: Minimizing errors reduces the costs associated with returns and customer dissatisfaction.

- Data-Driven Optimization: Real-time analytics enable continuous improvement in operations, driving further cost reductions and efficiency gains.

The exact ROI will depend on factors such as warehouse size, current operational costs, and order volume. However, companies that have implemented GreyOrange’s solutions typically report significant improvements in operational metrics within the first year. For a tailored ROI assessment, GreyOrange’s team can provide detailed insights based on specific business parameters.

Conclusion

GreyOrange warehouse automation software presents a robust solution for e-commerce shippers aiming to streamline their warehouse operations. By leveraging Artificial Intelligence and advanced robotics, GreyOrange enhances operational efficiency, accuracy, and scalability while reducing costs. Its comprehensive suite of features and successful track record in diverse implementations make it a valuable asset for businesses looking to optimize their supply chain and maintain a competitive edge in the e-commerce market.

One of the key benefits of GreyOrange's warehouse automation software is its ability to handle high volumes of orders. The software can process and fulfill orders quickly and accurately, which is essential for e-commerce businesses that need to meet customer demands in a timely manner. Additionally, the software's real-time tracking and reporting capabilities allow businesses to monitor their warehouse operations and make data-driven decisions to improve efficiency and reduce costs.

Another advantage of GreyOrange's warehouse automation software is its flexibility. The software can be customized to meet the specific needs of each business, whether it's a small e-commerce startup or a large enterprise. This means that businesses can implement the software at their own pace and scale up as needed, without having to worry about disrupting their existing operations. With GreyOrange's warehouse automation software, businesses can achieve a high level of automation and efficiency while still maintaining control over their warehouse operations.