Introduction to Nautical Manufacturing and Fulfillment

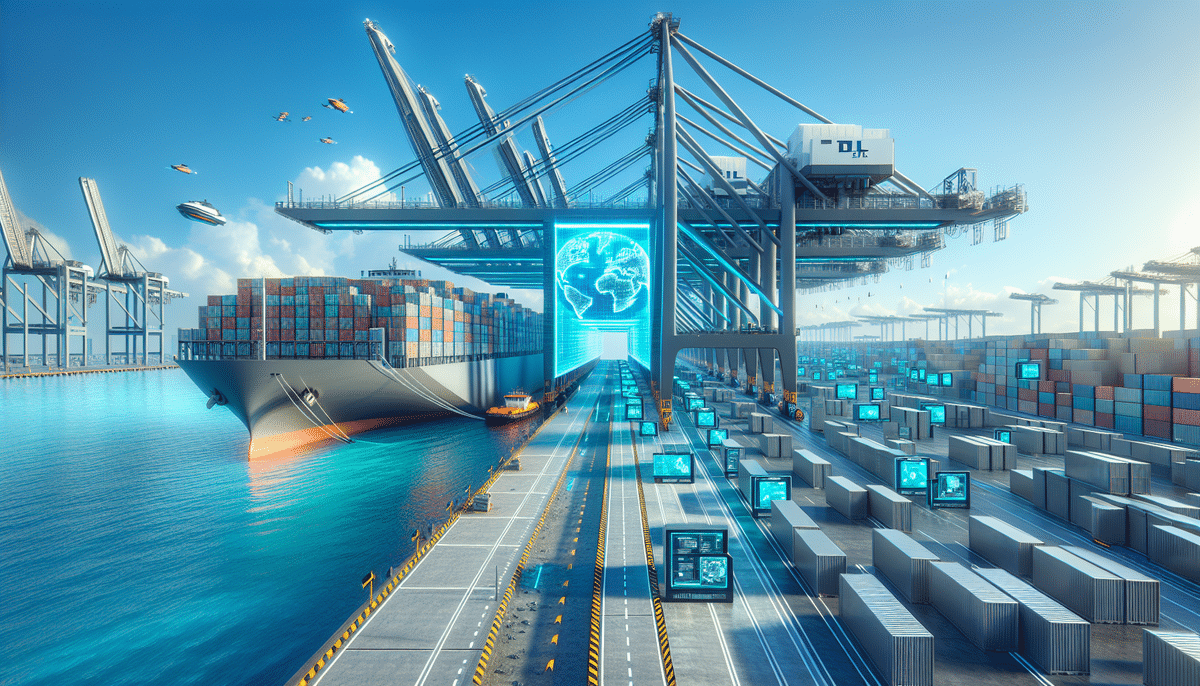

Nautical manufacturing and fulfillment is a specialized service offered by third-party logistics (3PL) partners tailored for businesses in the maritime industry, including boat manufacturers, fishing equipment suppliers, and marine accessory distributors. The nautical sector has experienced significant growth in recent years, driven by increasing demand for recreational boating and advancements in marine technologies. These services are designed to streamline the supply chain from production to final delivery, ensuring efficiency and reliability. This article delves into the key aspects of nautical manufacturing and fulfillment that businesses should consider when selecting 3PL logistics partners.

The Role of 3PL in Nautical Manufacturing and Fulfillment

Services Offered by 3PL Providers

3PL logistics providers offer a range of services that encompass the entire supply chain process. These services include warehousing, transportation, inventory management, and distribution. By leveraging advanced technologies, 3PL partners can oversee every step of the supply chain, from planning and forecasting to shipping and delivery. According to the Global 3PL Market Report, the adoption of real-time tracking technologies has increased by 40% in the past year, enhancing supply chain visibility and efficiency.

Benefits of Partnering with 3PL

Partnering with a 3PL provider allows nautical businesses to focus on their core competencies, such as product design and marketing, while outsourcing the complexities of logistics management. This collaboration results in significant cost savings and increased operational efficiency, as companies can utilize the expertise and resources of their 3PL partners. Additionally, 3PL providers offer customizable solutions tailored to the specific needs of each business, enhancing their value proposition.

Benefits of Using Nautical Manufacturing and Fulfillment

- Cost Reduction: Lower operational costs by outsourcing manufacturing and logistics.

- Supply Chain Optimization: Streamline operations for increased efficiency.

- Real-Time Visibility: Gain insights into supply chain status for informed decision-making.

- Access to Specialized Expertise: Benefit from industry-specific knowledge and equipment.

- Scalability: Easily scale operations to meet changing business needs.

Utilizing nautical manufacturing and fulfillment services offers numerous advantages to businesses in the nautical industry. These include reducing costs and optimizing supply chain operations through advanced technology, which provides real-time visibility into the supply chain process, enabling faster and more informed decisions [1]. Furthermore, outsourcing these services to a 3PL logistics provider can free up valuable resources, allowing businesses to concentrate on their primary activities.

Additionally, nautical manufacturing and fulfillment services grant businesses access to specialized expertise and equipment. This is particularly beneficial for small to medium-sized enterprises that may lack the resources to invest in their own manufacturing and fulfillment operations. By partnering with a 3PL provider, businesses can leverage the provider's expertise and infrastructure to enhance their operations and better serve their customers.

Key Features of Nautical Manufacturing and Fulfillment

- Comprehensive Supply Chain Management: Includes inventory management, transportation planning, and packaging optimization.

- Advanced Technology Systems: Provide real-time visibility and data-driven decision-making.

- Warehousing and Distribution: Ensure timely and efficient delivery of products.

- Specialized Handling: Capability to manage hazardous materials or oversized items.

- Customized Solutions: Offer flexible scheduling and tailored reporting to meet unique business needs.

3PL logistics providers offer several essential features in their nautical manufacturing and fulfillment services. Comprehensive supply chain management covers areas such as inventory management, transportation planning, and packaging optimization, ensuring end-to-end efficiency. Advanced technology systems are employed to monitor and manage operations, providing real-time visibility and facilitating data-driven decisions. According to industry studies, businesses utilizing advanced supply chain management systems report a 20% increase in operational efficiency.

Moreover, nautical manufacturing and fulfillment services offer specialized expertise in handling and transporting goods that require special care, such as hazardous materials or oversized items. These providers possess the necessary equipment and trained personnel to ensure safe and efficient handling throughout the supply chain. Customized solutions are also available to address the unique needs of each business, including flexible scheduling and tailored reporting. This level of personalized service helps businesses streamline their operations and improve their bottom line.

Choosing the Right 3PL Partner

- Experience and Reputation: Evaluate the partner's track record in the nautical industry.

- Service Offerings: Ensure they provide the specific services your business needs.

- Technology and Systems: Verify they have advanced systems for effective supply chain management.

- Cost: Consider their pricing structure and potential for cost savings.

- Location: Partnering with a provider near major ports or waterways can reduce transportation costs.

- Customer Service: Assess the quality of their customer support and responsiveness.

- Sustainability Practices: Ensure they prioritize eco-friendly operations and sustainability.

Selecting the right 3PL partner is crucial for maximizing the benefits of nautical manufacturing and fulfillment services. Businesses should assess potential partners based on their experience, reputation, and the range of services they offer. It's essential to ensure that the 3PL provider has the necessary technology and systems to effectively manage supply chain operations. Additionally, factors such as cost, location, and the quality of customer service should be meticulously evaluated.

Location is a key consideration; partnering with a 3PL provider situated near major ports or waterways can significantly reduce transportation costs and improve delivery times. According to shipping logistics studies, proximity to major transport hubs can decrease shipping times by up to 15%.

Furthermore, businesses should evaluate the sustainability practices of their potential 3PL partners. As the demand for eco-friendly products and services grows, it's imperative to partner with providers that prioritize sustainability in their operations. This includes the use of renewable energy sources, waste reduction initiatives, and environmentally-friendly transportation methods.

Overcoming Challenges in Nautical Manufacturing and Fulfillment

- Supply Chain Disruptions: Mitigate risks through advanced planning and forecasting.

- Inventory Control Issues: Optimize inventory management to prevent stockouts or excess inventory.

- Complex Product Requirements: Partner with knowledgeable providers who understand industry-specific needs.

- Managing Specialized Equipment: Ensure providers have the necessary expertise and equipment to handle specialized products.

Nautical manufacturing and fulfillment services can present challenges such as supply chain disruptions and inventory control issues. These challenges can be effectively mitigated by partnering with an experienced and reliable 3PL provider. Advanced planning, forecasting, and inventory optimization are essential strategies to prevent stockouts or excess inventory. Additionally, having contingency plans and backup suppliers can reduce the risk of disruptions.

The complexity of nautical products, which often require specialized knowledge and expertise, can make manufacturing and distribution more challenging. Working with partners who have experience in the nautical industry and understand the unique requirements of these products is crucial. This ensures that the manufacturing and fulfillment processes run smoothly, and customers receive high-quality products that meet their expectations.

The Role of Technology in Nautical Manufacturing and Fulfillment

- Supply Chain Management: Advanced systems track production, inventory, transportation, and distribution.

- Design and Production: Computer-aided design (CAD) software enables precise creation of 3D models.

- Marketing and Sales: E-commerce platforms and social media channels expand market reach.

Technology is integral to the efficiency and effectiveness of nautical manufacturing and fulfillment services. Advanced supply chain management systems track every aspect of the process, from production and inventory to transportation and distribution. This real-time visibility allows businesses to make informed decisions, reducing costs and enhancing operational efficiency. According to Supply Chain Digital, businesses implementing real-time tracking technologies experience a 30% improvement in supply chain visibility.

In the design and production phase, computer-aided design (CAD) software enables the precise creation of 3D models, facilitating the testing and refinement of designs before physical production. This not only conserves time and resources but also ensures that the final products meet the desired specifications.

Furthermore, technology has transformed marketing and sales strategies in the nautical industry. E-commerce platforms and social media channels allow businesses to reach a broader audience and sell products directly to consumers. This digital transformation has created new opportunities for small businesses and entrepreneurs to compete with larger companies by leveraging online sales channels.

Emerging Trends in Nautical Manufacturing and Fulfillment

- Automation: Use of robotics and artificial intelligence in production and warehousing.

- Eco-Friendly Practices: Implementation of alternative fuels and lean manufacturing principles.

- Customization and Personalization: Offering unique and customizable product options.

The nautical manufacturing and fulfillment industry is witnessing several emerging trends that are reshaping its landscape. One prominent trend is the adoption of automation in production and warehousing. Robotics and artificial intelligence streamline operations, improve efficiency, and reduce costs. According to Forbes, automation can lead to a 20% reduction in operational costs within the first year of implementation.

Another significant trend is the integration of eco-friendly practices. Businesses are increasingly adopting alternative fuels for transportation and implementing lean manufacturing principles to minimize waste. These sustainable practices not only reduce environmental impact but also often result in cost savings. For instance, transitioning to electric vehicles for transportation can lower fuel costs and decrease carbon emissions.

Customization and personalization are also gaining traction in the nautical industry. Consumers are seeking unique and personalized products, prompting businesses to offer customizable options. This trend demands a flexible and agile supply chain capable of adapting to changing customer preferences quickly. 3PL logistics providers play a vital role in facilitating this trend by offering customized fulfillment solutions that cater to the specific needs of businesses and their customers.

Case Studies: Successful Implementations with 3PL Partners

Numerous companies have successfully integrated nautical manufacturing and fulfillment services with the assistance of 3PL partners. For example, a boating accessories manufacturer partnered with a 3PL provider to optimize its supply chain through advanced inventory and transportation planning systems. This collaboration resulted in a 15% reduction in operational costs and a 20% improvement in delivery times.

Another case involves a boat manufacturer that worked with a 3PL provider to streamline its production and distribution processes. By utilizing the provider’s real-time tracking systems, the manufacturer achieved a 25% reduction in lead times and increased on-time deliveries to 95%, significantly enhancing customer satisfaction.

A yacht manufacturer partnered with a 3PL provider to manage its global supply chain more effectively. The provider assisted in optimizing inventory management, transportation planning, and customs compliance, which led to reduced lead times and improved on-time delivery performance. This partnership contributed to a 30% growth in sales over two years due to increased customer satisfaction and repeat business.

Additionally, a marine electronics company collaborated with a 3PL provider to enhance its fulfillment process. By optimizing warehouse operations, implementing a more efficient order management system, and improving shipping and delivery processes, the company reduced order processing time by 40% and achieved an order accuracy rate of 99.5%. These improvements led to higher customer satisfaction and increased repeat business.

Conclusion

Nautical manufacturing and fulfillment is a specialized service that offers significant benefits to businesses in the maritime industry. By partnering with an experienced and reliable 3PL logistics provider, companies can optimize their supply chain from production to final distribution, enhancing efficiency and reducing costs. As the industry continues to evolve, staying informed about emerging technologies and trends is essential. Collaborating with 3PL providers who are adept at adapting to these changes will help businesses achieve their goals and maintain a competitive edge. For more information on optimizing your nautical supply chain, visit ShipScience.