An Overview and Features of Relentless Fulfillment Centers for 3PL Logistics Fulfillment

As businesses continue to grow and expand their operations, the need for efficient and reliable logistics fulfillment solutions becomes increasingly essential. Enter 3PL logistics fulfillment, which provides businesses with outsourced logistics management services such as warehousing, order processing, and shipping. One of the innovative options for 3PL logistics fulfillment is Relentless Fulfillment Centers. This article offers an in-depth exploration of the basics, benefits, factors to consider, and case studies surrounding Relentless Fulfillment Centers.

Understanding the Basics of 3PL Logistics Fulfillment

3PL logistics fulfillment refers to the outsourcing of supply chain management functions to a third-party provider, allowing businesses to focus on their core competencies. 3PL companies offer services such as transportation management, distribution, warehousing, and order fulfillment. By outsourcing these non-core logistics functions, companies can save money and resources, enabling them to concentrate on product development, sales, and marketing initiatives.

One of the key benefits of using a 3PL provider is the flexibility it offers businesses. As companies grow and expand, their logistics needs may change. With a 3PL provider, businesses can easily scale their logistics operations up or down based on demand without the need for significant investments in additional resources or infrastructure. Additionally, 3PL providers often have access to advanced technology and expertise, helping businesses optimize their logistics operations and improve overall efficiency.

According to a Statista report, the global 3PL market is expected to continue its growth trajectory, reaching over $1 trillion in revenue by 2025. This growth underscores the increasing reliance of businesses on 3PL services to maintain competitive advantage in the market.

The Evolution of Fulfillment Centers: From Traditional Warehouses to Relentless Fulfillment Centers

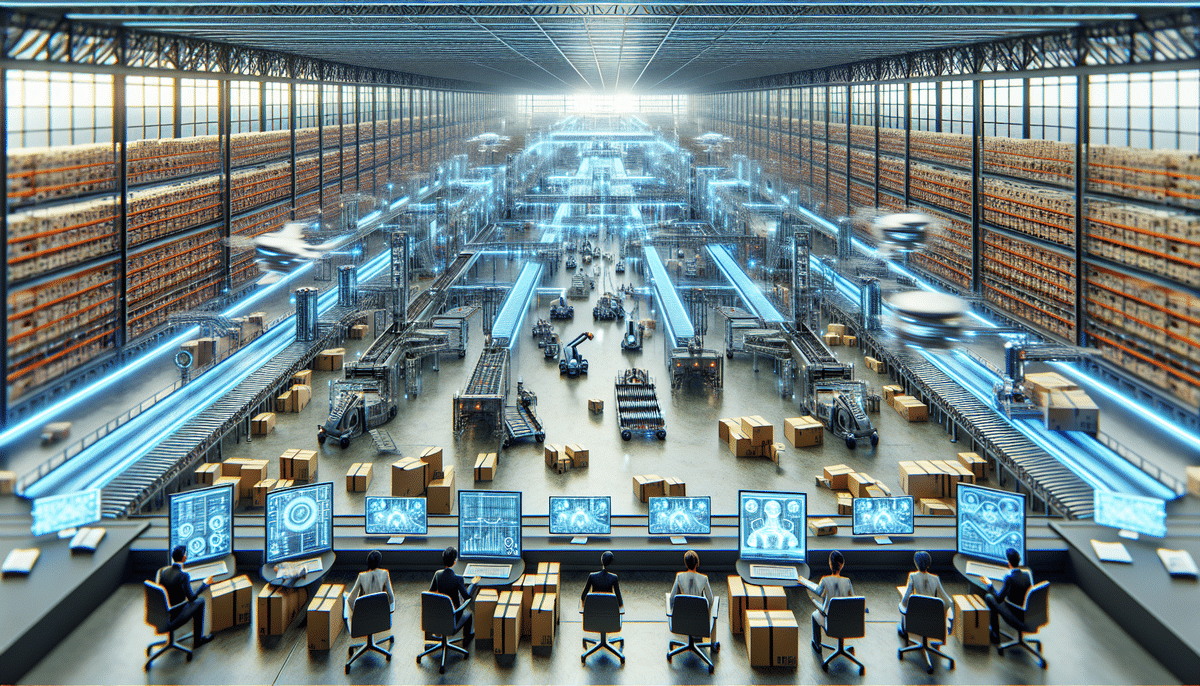

Relentless Fulfillment Centers represent a new era in warehousing solutions, designed to meet the dynamic demands of e-commerce, multiple sales channels, and global marketplaces. Traditional warehouses were primarily intended for long-term storage, but the rise of e-commerce requires businesses to process and distribute orders swiftly and efficiently. Relentless Fulfillment Centers are strategically located near major shipping hubs and metropolitan areas, enabling quick dispatch to customers. Equipped with high-tech machinery and advanced logistics technologies, these centers excel in order processing and shipping efficiency.

A significant advantage of Relentless Fulfillment Centers is their capacity to handle large volumes of orders during peak seasons. For instance, during the holiday season, e-commerce businesses often experience a surge in orders that can overwhelm traditional warehouses. However, Relentless Fulfillment Centers utilize advanced automation systems capable of managing high order volumes seamlessly, ensuring timely deliveries without compromising quality.

Benefits of Using Relentless Fulfillment Centers for 3PL Logistics Fulfillment

- Cost Efficiency: Relentless Fulfillment Centers offer lower operational costs through optimized logistics and distribution systems, reducing order-to-delivery cycle times, transportation expenses, and inventory levels.

- Faster Delivery: Enhanced logistics allow for quicker delivery times, improving customer satisfaction and loyalty.

- Enhanced Customer Experience: Reliable and swift delivery services contribute to a better overall customer experience, fostering repeat business.

- Scalability: Customized solutions enable businesses to scale their operations without worrying about logistics constraints.

Additionally, Relentless Fulfillment Centers excel in managing complex logistics and supply chain processes. Their expertise in inventory management, order processing, and shipping allows businesses to entrust the entire fulfillment process, freeing them to focus on other critical areas like product development and marketing.

Moreover, these centers provide customizable solutions tailored to the unique needs of various industries, including e-commerce, healthcare, and retail. This flexibility ensures that businesses can adapt to changing market demands without logistical hurdles.

How Relentless Fulfillment Centers Can Streamline Your Supply Chain Operations

Relentless Fulfillment Centers play a crucial role in streamlining supply chain operations by offering efficient and reliable distribution network infrastructures. They provide value-added services such as inventory management, packaging, labeling, and product assembly in a single location, thereby reducing freight and shipping costs while enhancing operational flexibility.

Furthermore, Relentless Fulfillment Centers offer real-time tracking and monitoring of inventory levels, order status, and delivery schedules. This visibility allows businesses to maintain better control over their supply chain operations, facilitating informed decision-making and swift responses to changes in demand or market conditions. Leveraging advanced technologies like automation, robotics, and artificial intelligence, these centers continuously optimize their processes to enhance efficiency, accuracy, and speed.

According to a McKinsey & Company report, integrating advanced technologies in fulfillment centers can increase operational efficiency by up to 30%, highlighting the importance of technology in modern supply chain management.

The Role of Technology in Relentless Fulfillment Centers for 3PL Logistics Fulfillment

Technology is integral to the operations of Relentless Fulfillment Centers. Advanced software systems automate the entire fulfillment process, from receiving orders to final delivery. Technologies such as real-time inventory management, warehouse management systems, and delivery tracking enhance space utilization, accuracy, and cost-effectiveness while minimizing errors.

In addition to software, Relentless Fulfillment Centers employ robotics and automation to streamline operations further. Automated guided vehicles (AGVs) transport goods within warehouses, and robotic arms facilitate efficient picking and packing of items. These technologies not only boost efficiency but also reduce the risk of workplace injuries.

Relentless Fulfillment Centers are continually adopting emerging technologies to maintain a competitive edge. For example, the use of drones for last-mile delivery is being explored to decrease delivery times and costs. Additionally, the integration of artificial intelligence and machine learning improves forecasting and optimizes inventory management, ensuring that businesses can meet customer demands effectively.

According to Forbes, the adoption of AI in fulfillment centers can lead to a 20-25% increase in operational efficiency and a significant reduction in operational costs.

Factors to Consider When Choosing a Relentless Fulfillment Center for Your Business

When selecting a Relentless Fulfillment Center, businesses should evaluate several critical factors:

- Location: Proximity to key marketplaces and major shipping hubs ensures faster delivery times.

- Infrastructure: Robust infrastructure and advanced technology support efficient operations.

- Scalability: The ability to scale operations based on demand fluctuations is essential.

- Pricing Policies: Flexible and transparent pricing structures accommodate varying business needs.

- Security Measures: Robust security protocols protect sensitive data and inventory.

Additionally, the level of customer service provided by the fulfillment center is crucial. A reliable partner should offer dedicated support teams available 24/7 to address any concerns or issues promptly, ensuring a seamless experience for both businesses and their customers.

Another important consideration is the technology and software utilized by the fulfillment center. Modern, efficient systems streamline the fulfillment process, reduce errors, and provide real-time tracking and reporting. These capabilities enable businesses to make informed decisions and optimize their operations for maximum efficiency and profitability.

Case Studies: Success Stories from Companies That Have Utilized Relentless Fulfillment Centers

Several companies have achieved significant success by partnering with Relentless Fulfillment Centers. For example, furniture retailer Wayfair outsourced its distribution network to a specialized fulfillment partner. This partnership resulted in a 40% increase in sales within the first year, thanks to the highly automated and efficient warehouse operations.

In the retail sector, giants such as Walmart, Target, Sephora, and Adidas have also benefited from streamlined operations and enhanced efficiency provided by Relentless Fulfillment Centers.

Another notable example is Amazon, which leverages multiple Relentless Fulfillment Centers across the United States to improve delivery times and boost customer satisfaction. By outsourcing fulfillment operations, Amazon has been able to focus on product development and marketing, maintaining its position as a leading online retailer.

For more detailed case studies, refer to industry reports from sources like Business Insider and Harvard Business Review.

The Future of Relentless Fulfillment Centers and 3PL Logistics Fulfillment

The ongoing growth of e-commerce and advancements in technology will continue to shape the future of the logistics and fulfillment industry. Relentless Fulfillment Centers are poised to play a pivotal role in developing new strategies, technologies, and infrastructures that benefit businesses globally.

One significant area of impact is the development of sustainable logistics practices. As consumer awareness regarding environmental issues increases, businesses face pressure to reduce their carbon footprint. Relentless Fulfillment Centers can assist businesses in achieving sustainability goals by implementing eco-friendly practices such as optimizing delivery routes, utilizing electric vehicles, and minimizing packaging waste.

Furthermore, the integration of automation and robotics will continue to drive innovation in Relentless Fulfillment Centers. With the advancement of artificial intelligence and machine learning, these technologies become more sophisticated and cost-effective. Relentless Fulfillment Centers can harness these innovations to enhance efficiency, accuracy, and speed in the fulfillment process, leading to faster delivery times and heightened customer satisfaction.

According to a Forbes article, the future of fulfillment centers lies in the seamless integration of AI and sustainable practices, which will be crucial for meeting the evolving demands of the market.

Common Misconceptions About Relentless Fulfillment Centers and 3PL Logistics Fulfillment

There are several misconceptions surrounding Relentless Fulfillment Centers and 3PL logistics fulfillment. One common misconception is that outsourcing these services leads to job losses. In reality, 3PL providers enhance the efficiency and productivity of supply chains, which can result in increased profitability and job creation within the logistics sector.

Another misconception is that businesses lose control over their logistics operations when partnering with a 3PL provider. On the contrary, businesses can maintain significant control over their logistics processes, focusing on their core competencies while relying on the expertise of 3PL providers to manage fulfillment operations effectively.

Additionally, some believe that 3PL services are only suitable for large enterprises. However, 3PL providers offer scalable solutions that can benefit businesses of all sizes, from startups to multinational corporations, by providing tailored services that match their specific needs.

Key Performance Indicators (KPIs) to Measure the Effectiveness of Your Relentless Fulfillment Center Partnership

To ensure a successful partnership with a Relentless Fulfillment Center, businesses should monitor specific key performance indicators (KPIs), including:

- Order Accuracy Rate: Measures the accuracy of order fulfillment and reduces errors.

- Order Cycle Time: Tracks the time taken from order placement to delivery.

- Customer Satisfaction: Assesses the overall satisfaction of customers with delivery services.

- Order-to-Delivery Time: Monitors the efficiency of the entire fulfillment process.

- Inventory Turnover: Evaluates how efficiently inventory is managed and rotated.

- Return Rate: Measures the percentage of orders returned by customers.

These KPIs provide valuable insights into the performance of the fulfillment partnership, highlighting areas for improvement and ensuring that operational efficiencies are continuously enhanced. Regularly reviewing these metrics helps businesses maintain high standards of service and adapt to changing market conditions effectively.

Best Practices for Managing a Successful Partnership with a Relentless Fulfillment Center for 3PL Logistics Fulfillment

Managing a successful partnership with a Relentless Fulfillment Center involves:

- Open Communication: Maintain transparent and frequent communication to address any issues promptly.

- Frequent Reviews: Regularly assess performance metrics and adjust strategies as needed.

- Alignment of Goals: Ensure that both parties share common objectives and performance milestones.

- Embrace Innovation: Invest in emerging technologies and innovative practices to stay competitive.

- Continuous Improvement: Foster a culture of continuous improvement to enhance processes and services.

By fostering a collaborative and adaptive partnership, businesses and fulfillment centers can achieve mutual success and drive growth effectively. Establishing clear expectations, setting measurable goals, and maintaining a proactive approach to problem-solving are essential components of a successful 3PL partnership.

In conclusion, partnering with a Relentless Fulfillment Center for 3PL Logistics Fulfillment offers businesses a robust solution for streamlining supply chain operations, enhancing customer experiences, and driving revenue growth. These advanced logistics centers leverage innovative technologies, strategically located infrastructures, and optimized processes to deliver effective and efficient logistics and distribution services, leading to increased profitability and scalability.