Introduction to Automated Warehouse Solutions

In today's fast-paced business environment, warehouse automation has become a critical factor for enhancing efficiency and productivity. Automated warehouse solutions utilize advanced technologies, such as robotics and integrated systems, to manage inventory and streamline operations. Two prominent systems in this space are AutoStore and Dematic. Understanding the differences between these systems is essential for businesses looking to optimize their warehouse operations.

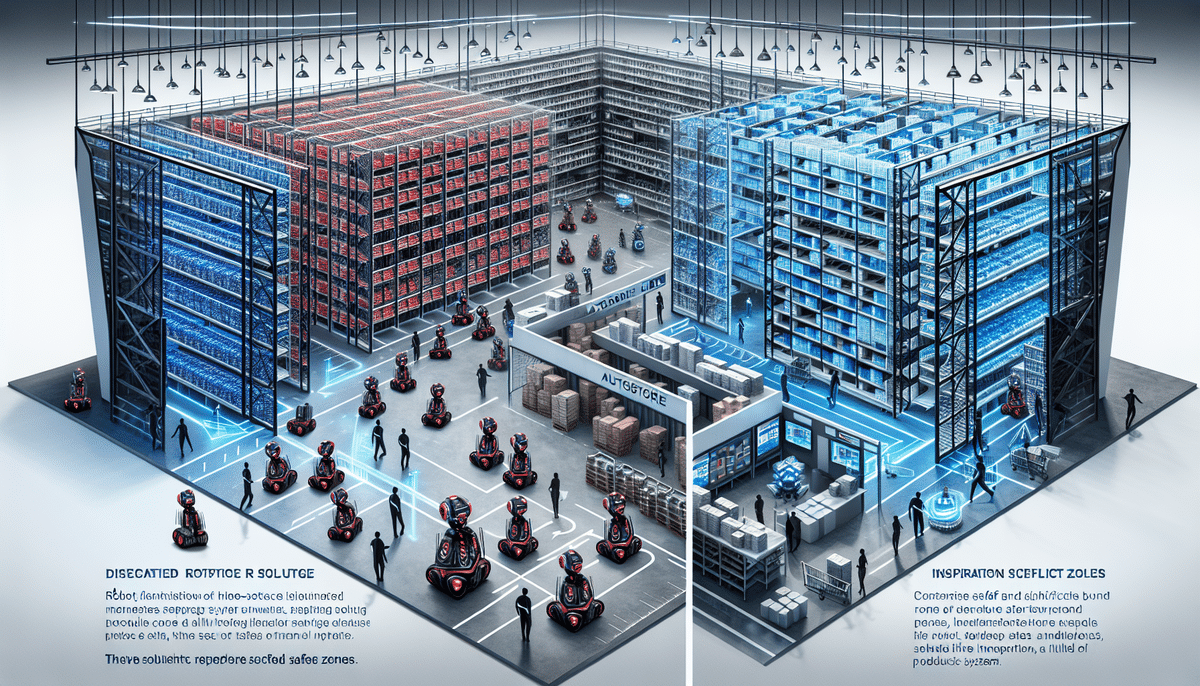

Comparing AutoStore and Dematic Systems

Storage Approach

AutoStore employs a grid-based cube storage system where products are stored in bins stacked within a compact grid. This high-density storage maximizes space efficiency, making it ideal for businesses with limited warehouse space.

Dematic, on the other hand, utilizes traditional shelving systems with adjustable shelves. This allows for greater flexibility in accommodating various product sizes and types, catering to diverse inventory needs.

Scalability

AutoStore is renowned for its modular scalability. Businesses can easily expand their system by adding more bins and robots without significant structural changes to the warehouse.

Dematic offers scalability through more extensive modifications, which can accommodate larger volumes and more complex warehouse processes. This makes Dematic suitable for larger operations with evolving storage requirements.

Integration Capabilities

AutoStore provides standardized integration with existing Warehouse Management Systems (WMS), ensuring a smoother implementation process.

Dematic offers more customization options, allowing tailored integrations to meet specific business needs and existing infrastructure.

Cost-Effectiveness and Scalability

Cost is a significant consideration when choosing between AutoStore and Dematic. According to a Forbes analysis, AutoStore can reduce overall system costs by approximately 20% compared to traditional systems by requiring less warehouse space and having lower installation and maintenance costs.

While AutoStore offers substantial upfront savings, Dematic's flexibility may provide better long-term value for larger enterprises with complex and evolving storage needs.

Additionally, AutoStore's modular design allows for budget-friendly scalability, making it an attractive option for businesses anticipating steady growth.

Storage Capacity and Flexibility

AutoStore features a high-density storage system that maximizes space utilization, making it ideal for businesses with limited warehouse areas. This system allows for easy expansion by adding more modules as storage needs grow.

Dematic offers a broader storage capacity, suitable for companies requiring extensive storage for a wide range of products, including larger items. Dematic's adaptable shelving systems can handle diverse inventory types, providing greater flexibility across various industries.

According to a ResearchGate study, Dematic's advanced software and automation capabilities enhance efficiency and accuracy, potentially offsetting the need for additional storage space.

Installation and Maintenance

AutoStore is generally easier and faster to install due to its standardized, modular design. This results in reduced downtime and a quicker return on investment.

Dematic installations are typically more time-consuming and complex, requiring significant planning and customization. However, Dematic provides comprehensive maintenance support services to ensure system reliability.

Maintenance requirements differ as well. AutoStore's simpler architecture allows for easier and quicker repairs, minimizing operational disruptions. In contrast, Dematic's more complex systems may require specialized maintenance, potentially leading to higher costs and longer repair times. A Logistics Management report indicates that businesses using AutoStore experience lower maintenance-related disruptions compared to those using traditional systems like Dematic.

Impact on Warehouse Productivity and Safety

Both AutoStore and Dematic significantly enhance warehouse productivity by automating tasks such as picking, packing, and inventory management. Automation reduces manual labor, increases order fulfillment speed, and improves accuracy.

A case study by Automate.org reported that implementing AutoStore led to a 25% increase in order fulfillment speed and a 15% reduction in picking errors. Similarly, Dematic systems have been shown to improve warehouse throughput by up to 30% in large-scale operations.

In terms of safety, both systems incorporate advanced safety features like automated sensors and emergency stop mechanisms. By automating repetitive and physically demanding tasks, these systems reduce the risk of workplace injuries and accidents. The Occupational Safety and Health Administration (OSHA) emphasizes the importance of integrating automated safety systems with comprehensive training programs to maximize workplace safety.

Real-World Implementations

Numerous leading companies have successfully implemented AutoStore and Dematic technologies to optimize their warehouse operations:

- ASOS: Implemented an AutoStore system to improve order fulfillment speed and accuracy.

- Toyota Material Handling North America: Utilized Dematic systems to streamline their material handling processes.

- Amazon: Integrated both AutoStore and Dematic technologies across various warehouses to enhance their distribution network.

- Walmart: Uses Dematic systems to manage extensive inventory and ensure efficient product distribution.

- DHL: Adopted an AutoStore system in their Norwegian warehouse, resulting in increased efficiency and accuracy in order fulfillment.

Future Trends in Warehouse Automation

The future of automated warehouse solutions is set to evolve with advancements in artificial intelligence (AI), machine learning, and the Internet of Things (IoT). These technologies will enable more intelligent and interconnected warehouse operations.

AI and Machine Learning: These technologies will optimize operations by analyzing data and making real-time decisions, such as predicting product demand trends and adjusting inventory levels accordingly.

IoT Integration: Enhanced connectivity and data sharing across warehouse systems will lead to more streamlined operations and better resource management.

Autonomous Mobile Robots (AMRs): AMRs offer greater flexibility and adaptability compared to traditional automated guided vehicles (AGVs), revolutionizing warehouse logistics.

For AutoStore and Dematic, integrating these emerging technologies will be crucial to maintaining their competitive edge and meeting the future demands of automated warehousing.

Conclusion: Choosing Between AutoStore and Dematic

Deciding between AutoStore and Dematic depends on the specific needs and goals of your business:

- Space Constraints: AutoStore is ideal for businesses with limited warehouse space due to its high-density storage capabilities.

- Scalability Needs: Dematic is better suited for larger warehouses with complex and evolving storage requirements.

- Cost Considerations: AutoStore offers lower initial and maintenance costs, making it suitable for businesses with budget constraints.

- Product Range: AutoStore excels with smaller items, while Dematic can handle a broader range of products, including larger items.

- Customization: Dematic provides more extensive customization options, allowing for tailored solutions based on specific warehouse processes.

Ultimately, the choice should align with your operational goals, budget, and long-term growth plans. Consulting with warehouse automation experts and conducting pilot implementations can also help in making an informed decision.