Introduction to Autonomous Mobile Robots in Warehousing

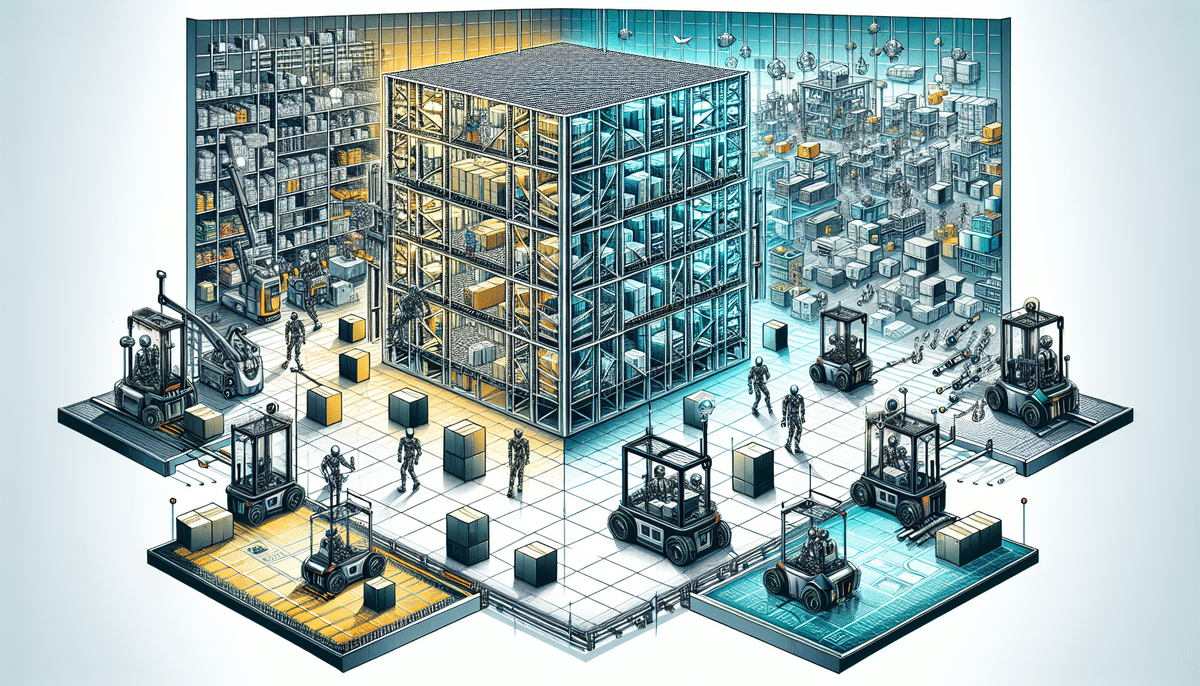

In the rapidly evolving landscape of warehousing and logistics, automation technology has become essential for enhancing operational efficiency and speed. Autonomous Mobile Robots (AMRs) are at the forefront of this transformation, providing scalable solutions to meet the growing demands of modern businesses. Among the leading innovators in the AMR sector are AutoStore and Fetch Robotics. This article offers a comprehensive comparison of these two industry leaders, examining their technologies, features, and suitability for various business needs.

Company Overview: AutoStore vs. Fetch Robotics

AutoStore: Pioneers in High-Density Storage Solutions

AutoStore, established in 1996 and headquartered in Norway, has revolutionized warehouse storage with its innovative cube-based system. This system leverages a grid of bins and robots to maximize space utilization, enabling the storage of up to four times more products compared to traditional shelving.

Fetch Robotics: Leaders in Collaborative Automation

Fetch Robotics, founded in 2014 and based in California, focuses on developing collaborative robots that work alongside human operators. Their versatile AMRs are designed for a variety of tasks, including fetching, transporting, and assisting with inventory management, making them adaptable to diverse industry requirements.

Technology and Features

AutoStore Technology and Features

- Cube-Based Storage System: Utilizes a grid of stacked bins, allowing for high-density storage and efficient space utilization.

- High Speed: Robots operate at speeds up to 4 meters per second, facilitating rapid item retrieval and storage.

- Scalability: The modular design allows for easy expansion, accommodating growing inventories without significant infrastructure changes.

- Real-Time Inventory Management: Integrated sensors provide accurate, up-to-date tracking of inventory levels.

These features make AutoStore a preferred choice for large-scale retailers and logistics companies seeking efficient and scalable storage solutions.

Fetch Robotics Technology and Features

- Collaborative Operation: Designed to work seamlessly alongside human workers, enhancing productivity without replacing human roles.

- Versatile Task Management: Capable of performing a wide range of tasks, including order picking, transportation, and inventory scanning.

- Advanced Safety Systems: Equipped with sensors and cameras to navigate complex environments and avoid collisions.

- Easy Integration: Compatible with existing warehouse management systems, enabling smooth workflow integration.

Fetch Robotics' emphasis on collaboration and flexibility makes their AMRs suitable for industries that require adaptability and human-robot interaction.

Design, Functionality, and Efficiency

Design Differences

The primary design distinction between AutoStore and Fetch Robotics lies in their approach to storage and navigation. AutoStore’s fixed grid system optimizes for high-density storage, whereas Fetch Robotics’ free-moving AMRs offer greater flexibility in warehouse layout and design.

Operational Efficiency

Both systems significantly boost operational efficiency but in different ways. AutoStore’s high-speed robots and dense storage capabilities facilitate rapid item handling, ideal for environments with high turnover rates. Fetch Robotics enhances efficiency through task versatility and seamless human-robot collaboration, making it suitable for dynamic settings where adaptability is crucial.

Cost-Effectiveness and Reliability

Cost Analysis

AutoStore typically requires a substantial initial investment due to its specialized infrastructure and high-density storage systems. However, this upfront cost can be offset by long-term savings achieved through increased storage capacity and operational efficiency. On the other hand, Fetch Robotics offers a more flexible and potentially lower-cost implementation, especially for smaller warehouses or those needing adaptable layouts.

Reliability Factors

Both AutoStore and Fetch Robotics boast robust performance records. AutoStore’s structured system ensures consistent reliability in high-density environments, while Fetch Robotics’ advanced sensor systems and collaborative features provide reliable operation in dynamic settings. Regular maintenance and system updates are essential for maintaining optimal performance in both solutions.

Speed and Efficiency in Warehouse Operations

Performance Metrics

AutoStore’s robots can achieve speeds of up to 4 meters per second, enabling swift item retrieval and storage. This high speed is complemented by the system’s ability to handle large volumes of small items efficiently. Fetch Robotics’ AMRs, while slightly slower, excel in performing multiple tasks simultaneously, thereby enhancing overall warehouse efficiency.

Efficiency Enhancements

Key factors influencing speed and efficiency include:

- Item Size and Weight: AutoStore is optimized for smaller items, facilitating quick storage and retrieval. Fetch Robotics can handle a broader range of item sizes and weights, offering greater operational versatility.

- Warehouse Layout: AutoStore requires a predefined grid layout, optimizing speed within that structure. Fetch Robotics’ free-moving nature allows for flexible and adaptable layouts, enhancing efficiency in varied environments.

- System Integration: AutoStore integrates seamlessly with warehouse management systems for real-time tracking, while Fetch Robotics provides customizable integration options to suit specific workflow requirements.

The choice between the two depends on the specific operational needs and product characteristics of the warehouse.

Industry Use Cases and Business Suitability

Use Cases Across Industries

- E-Commerce: AutoStore’s high-density storage effectively manages extensive inventories, enabling rapid order fulfillment. Fetch Robotics supports flexible order processing and real-time inventory management.

- Retail: AutoStore enhances stock management and shelf replenishment, while Fetch Robotics assists with inventory audits and customer service tasks.

- Healthcare: Fetch Robotics excels in transporting medical supplies and equipment within hospital settings, ensuring timely availability and reducing manual handling.

- Manufacturing: Both systems facilitate material handling, with AutoStore optimizing component storage and Fetch Robotics supporting assembly line operations.

Suitability for Business Sizes

Small to Medium-Sized Businesses (SMBs): Fetch Robotics offers an affordable and flexible solution for SMBs, allowing easy integration into existing workflows without significant infrastructure changes. This makes it ideal for businesses aiming to scale operations without large upfront investments.

Large-Scale Fulfillment Centers: AutoStore is better suited for large-scale operations due to its high-density storage capabilities and fast item retrieval times. The ability to store a vast number of products in a compact space significantly enhances operational efficiency in large facilities.

Future Trends in Autonomous Mobile Robots

The future of AMRs looks promising, with advancements in artificial intelligence, machine learning, and sensor technologies poised to make AMRs even more intelligent and adaptable. For AutoStore and Fetch Robotics, these developments mean opportunities to integrate sophisticated features such as enhanced data analytics, improved autonomous decision-making, and better interoperability with other warehouse systems.

As businesses increasingly prioritize automation to stay competitive, both AutoStore and Fetch Robotics are well-positioned to lead the market. Their ongoing innovation and ability to evolve with changing industry needs will be pivotal in defining the future of warehouse and logistics automation.