Choosing Between AutoStore and Geek+ for Warehouse Automation

If you're in the market for a warehouse automation system, you've likely encountered AutoStore and Geek+. These industry leaders offer advanced robotics solutions designed to enhance efficiency and productivity in warehouses worldwide. While both companies provide impressive systems, they cater to different needs and preferences. This comprehensive comparison will help you determine which system aligns best with your warehouse requirements.

Overview of AutoStore and Geek+ Systems

Understanding the core offerings of each company is crucial before diving into a detailed comparison.

AutoStore

AutoStore is a Norwegian company renowned for its robotic storage and retrieval systems. Their innovative approach utilizes a grid of self-contained storage bins stacked vertically, with robots navigating the grid to access and retrieve items efficiently. This design is celebrated for its high-density storage capabilities and rapid picking times, making it ideal for high-volume warehouses.

Geek+

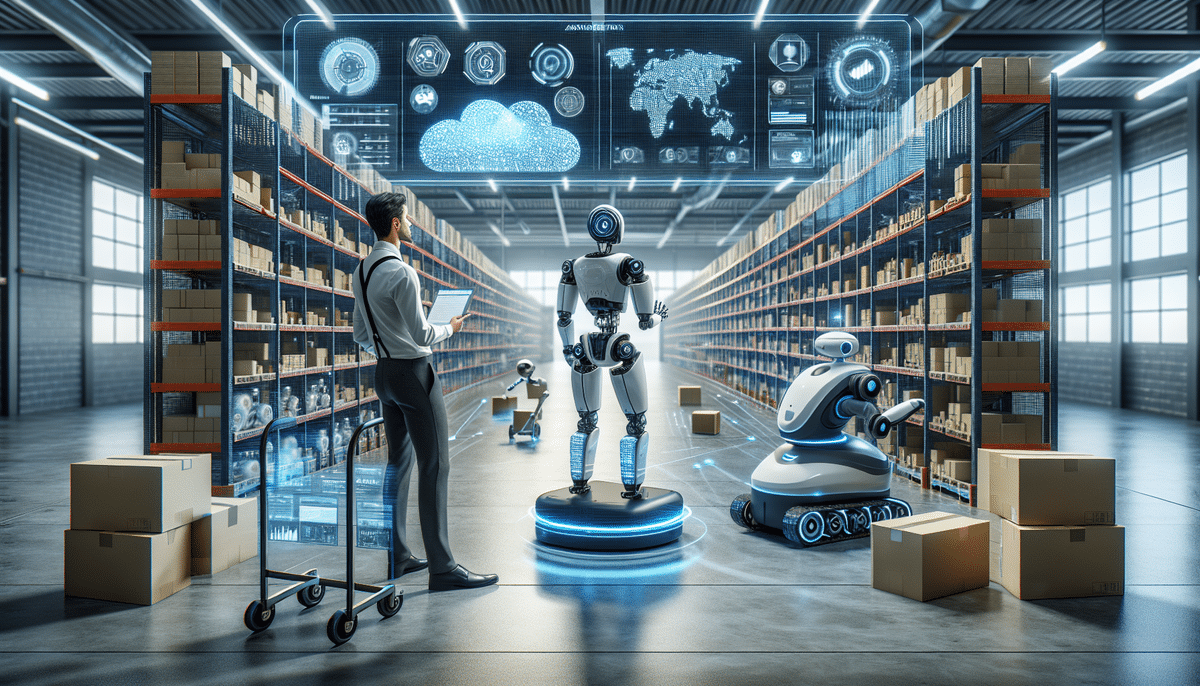

Geek+, a Chinese-based company, offers a diverse range of robotics solutions tailored to various warehouse operations. Their systems encompass robotic sorting, picking, packing, and palletizing, providing flexibility and scalability. Geek+'s solutions are designed to integrate seamlessly with human workers, enhancing overall workflow and adaptability.

Comparative Analysis: AutoStore vs Geek+

Let's delve into the key differences and similarities between AutoStore and Geek+ to better understand which system may suit your warehouse needs.

Storage and Retrieval Systems

AutoStore's grid-based system allows for extremely high-density storage, optimizing floor space utilization. The robots can swiftly access any bin within the grid, significantly reducing picking times. According to a Forbes report, AutoStore systems can increase storage capacity by up to 75% compared to traditional shelving.

Geek+ offers versatile storage and retrieval solutions, including robotic sorting systems that enhance the efficiency of item categorization and transportation. Their automated pallet storage solutions are particularly beneficial for larger warehouses, providing scalability as operations grow.

Picking and Packing Efficiency

AutoStore focuses primarily on automated storage and retrieval but also provides solutions for automated picking and packing. The robots can efficiently transfer items from storage bins to packing stations, streamlining the order fulfillment process.

Geek+ excels in automated picking and packing with robotic arms capable of handling items directly from shelves or conveyors. Their systems also support automated bagging and boxing, reducing manual labor and increasing accuracy. A study by McKinsey & Company highlights that Geek+'s solutions can improve picking accuracy by up to 99.9%.

Flexibility and Scalability

Geek+ stands out for its flexibility and scalability. Their modular systems can be easily expanded or reconfigured to meet evolving warehouse demands. This adaptability makes Geek+ a preferred choice for warehouses anticipating growth or changes in inventory management.

AutoStore, while highly efficient for automated storage and retrieval, offers less flexibility in adapting to complex workflows. Its specialized system is best suited for environments with consistent storage and retrieval needs.

Cost Considerations

Cost is a pivotal factor when selecting a warehouse automation system. AutoStore systems tend to be more expensive due to the advanced technology and higher cost of self-contained storage bins. Additionally, customization requirements can increase the overall implementation cost.

In contrast, Geek+ offers more budget-friendly solutions, making their systems accessible to smaller warehouses or those with limited budgets. The scalability of Geek+'s systems also allows for incremental investments, aligning costs with growth and demand.

Pros and Cons: AutoStore vs Geek+

Evaluating the advantages and disadvantages of each system can provide clarity in making an informed decision.

AutoStore

- Pros:

- High-density storage maximizing floor space

- Fast and efficient picking times

- Proven reliability in high-volume operations

- Cons:

- Higher initial investment cost

- Limited flexibility for complex or variable workflows

- Potentially longer implementation time due to customization

Geek+

- Pros:

- Flexible and scalable systems adaptable to changing needs

- Lower cost of entry compared to AutoStore

- Enhanced integration with human workers, fostering collaborative environments

- Cons:

- May not achieve the same storage density as AutoStore

- Potentially higher reliance on manual processes in certain areas

- Varied performance depending on specific implementation

Real-World Implementations and Results

Both AutoStore and Geek+ have been successfully deployed in various warehouses worldwide, demonstrating significant improvements in operational efficiency.

Geek+ Success Stories

A warehouse in Shanghai integrated Geek+'s robotic sorting system, resulting in a 70% reduction in sorting time. This enhancement allowed the facility to handle a greater volume of packages efficiently, as highlighted in a Geek+ case study.

Making the Right Choice for Your Warehouse

When selecting between AutoStore and Geek+, consider the following factors to ensure the chosen system aligns with your operational goals:

- Operational Needs: Assess whether your warehouse prioritizes high-density storage and rapid retrieval or requires flexible, scalable solutions that adapt to changing workflows.

- Budget Constraints: Determine your budget for initial investment and ongoing maintenance to choose a system that offers the best value.

- Future Growth: Consider the scalability of the system to accommodate future expansion and increased inventory without significant overhauls.

- Integration with Existing Systems: Evaluate how easily the new automation system can integrate with your current warehouse management systems and processes.

By carefully weighing these considerations, you can select a warehouse automation system that not only meets your current needs but also supports future growth and efficiency.

Conclusion

Both AutoStore and Geek+ offer robust solutions for warehouse automation, each with its unique strengths. AutoStore excels in providing high-density storage and swift retrieval, making it ideal for high-volume warehouses. On the other hand, Geek+'s flexible and scalable systems are well-suited for warehouses seeking adaptable automation that can grow alongside their operations.

Ultimately, the best choice depends on your specific warehouse requirements, budget, and long-term operational goals. By conducting a thorough analysis and considering the factors outlined above, you can implement a robotics system that enhances efficiency, reduces costs, and drives productivity in your warehouse.