AutoStore vs Knapp: Choosing the Right ASRS for Your Warehouse

Automated Storage and Retrieval Systems (ASRS) are revolutionizing warehouse operations by enhancing efficiency and productivity. Selecting the appropriate ASRS is crucial, as it directly impacts your warehouse's performance. This comprehensive comparison between AutoStore and Knapp aims to provide the insights needed to make an informed decision.

What Are Automated Storage and Retrieval Systems (ASRS)?

Definition and Benefits

ASRS are computer-controlled systems designed to automatically place and retrieve loads from defined storage locations. These systems optimize space utilization, reduce manual handling, minimize errors, and enhance safety in warehouses. According to the Warehousing Industry Report, implementing ASRS can increase storage capacity by up to 75%.

Key Components of ASRS

- Storage Modules: The physical structures where items are stored, such as bins or trays.

- Retrieval Mechanisms: Robots or shuttles that access and transport items.

- Control Software: Manages inventory and directs the movement of retrieval mechanisms.

In-Depth Comparison: AutoStore vs Knapp

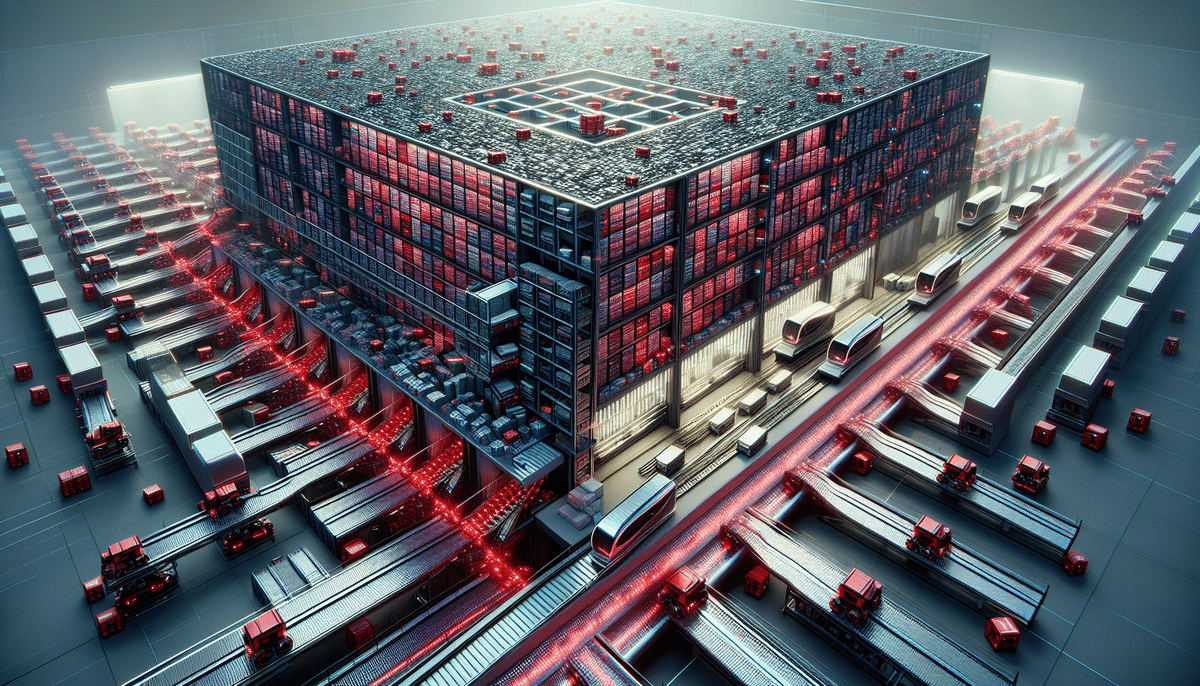

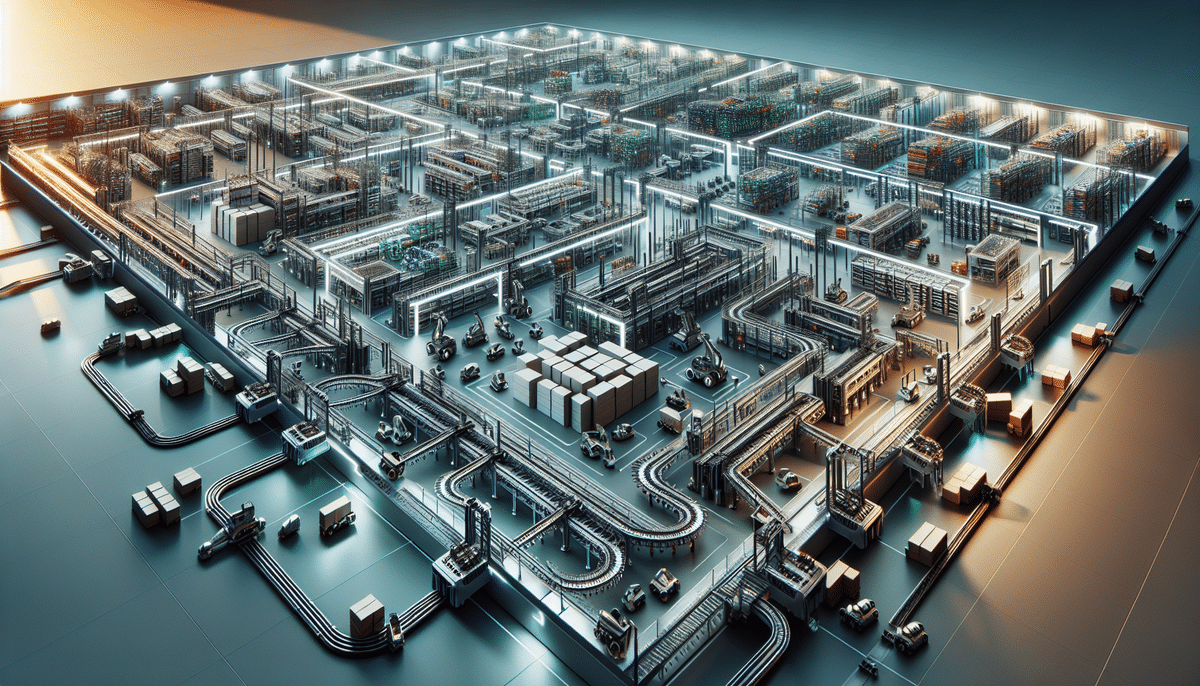

System Architecture and Design

AutoStore utilizes a cube-style structure where items are stored in bins stacked within a grid. Collaborative robots, or "cobots," navigate the grid to retrieve and transport bins to workstations. This design allows for high-density storage, making it ideal for warehouses with limited space.

Knapp, on the other hand, employs a shuttle-style system. Items are stored on trays that are moved by shuttles along tracks to picking stations. This system is optimized for speed and can handle larger trays, suitable for high-throughput environments.

Scalability and Flexibility

AutoStore offers seamless scalability by adding more cubes and robots as inventory grows. Its modular nature makes it adaptable to various warehouse sizes and changing business needs. In contrast, Knapp's shuttle system requires more extensive infrastructure for expansion, which can be a limitation for rapidly growing operations.

Performance and Efficiency

AutoStore is renowned for its energy-efficient design and high storage density. Studies have shown that warehouses using AutoStore can achieve up to a 20% reduction in energy consumption compared to traditional systems (Warehouse IQ Study).

Knapp excels in retrieval speed, with its shuttle system capable of faster item access and transportation. This results in quicker order fulfillment times, which is critical for businesses with high-volume demands.

Cost Analysis

Initial installation costs for AutoStore are generally lower due to its simpler design and smaller footprint. The cost per bin ranges from $400 to $800, making it a cost-effective option for many businesses. However, long-term maintenance costs are relatively low, enhancing overall cost-efficiency.

Knapp systems have higher upfront costs, with trays priced between $2,000 to $4,000 each. While the initial investment is substantial, Knapp's robust design may require less frequent maintenance, potentially balancing long-term expenses.

Features of AutoStore ASRS

- High-Density Storage: Bins can be stacked up to 16 levels high, maximizing warehouse space.

- Collaborative Robots: Cobots work alongside human operators, enhancing safety and productivity.

- Modular Design: Easily expandable and customizable to meet specific warehouse needs.

- Advanced Software: Optimizes storage and retrieval processes for maximum efficiency.

Advantages of the Knapp ASRS System

- High Load Capacity: Each tray can handle up to 1,000kg, suitable for heavy-duty applications.

- Speedy Retrieval: Shuttles transport trays directly to picking stations, reducing order processing times.

- Customization: Advanced software allows for tailored warehouse management solutions.

- Safety Features: Includes automatic tray braking and collision avoidance to prevent accidents.

Real-World Implementations

AutoStore Success Stories

Companies like H&M and Puma have successfully implemented AutoStore systems, resulting in significant improvements in warehouse efficiency and space utilization. Norwegian retailer Elkjøp reported a 60% increase in productivity and a 50% reduction in floor space usage after adopting AutoStore.

Knapp Success Stories

Retail giants such as John Lewis and dm-drogerie markt have integrated Knapp's ASRS systems, leading to a 30% boost in productivity and a 50% decrease in order errors. These implementations demonstrate Knapp's capability to enhance large-scale warehouse operations.

Future Developments in ASRS Technology

The ASRS landscape is rapidly evolving with advancements in artificial intelligence and data analytics. Future developments focus on improving energy efficiency through renewable energy sources and smart technologies like regenerative braking systems. Both AutoStore and Knapp are investing in research and development to incorporate these innovations, ensuring their systems remain at the forefront of warehouse automation.

Moreover, the integration of IoT devices and machine learning algorithms is expected to further optimize inventory management and predictive maintenance, reducing downtime and operational costs.

Conclusion: Making the Right Choice

Both AutoStore and Knapp offer robust ASRS solutions, each with its unique strengths. AutoStore is ideal for businesses seeking high-density storage and scalability with lower initial costs. Knapp excels in environments requiring fast retrieval speeds and handling large, heavy loads. Assessing your warehouse's specific needs, budget, and growth projections is essential in determining the best fit.

Consider factors such as the level of automation required, long-term cost implications, and the technical expertise of your staff when making your decision. With the right ASRS, your warehouse operations can achieve enhanced efficiency, accuracy, and profitability.

Additional Considerations

- Customization Needs: AutoStore offers greater flexibility for modifications, whereas Knapp may require more extensive customization.

- Technical Expertise: AutoStore's user-friendly interface is easier for staff to operate, whereas Knapp systems may demand specialized training.

- Maintenance Requirements: AutoStore's simpler design translates to less maintenance, while Knapp's complex systems may require more frequent upkeep.