Understanding Dry Ice for Shipping Perishables

Dry ice, the solid form of carbon dioxide, is a widely used cooling agent in the shipping industry. With a temperature of approximately -109.3°F (-78.5°C), dry ice effectively maintains low temperatures necessary for preserving perishable items during transit.

What is Dry Ice?

Dry ice is the solid state of carbon dioxide (CO2), created by compressing and cooling gaseous CO2 until it becomes a solid. Unlike regular ice, dry ice does not melt into a liquid but sublimates directly into gas, making it ideal for shipping applications where moisture is undesirable.

How Dry Ice Maintains Low Temperatures

When placed in an insulated container, dry ice sublimates at a controlled rate, releasing cold CO2 gas that keeps the surrounding environment consistently cold. This process ensures that perishable goods remain at safe temperatures throughout the shipping journey.

Benefits of Using Dry Ice in Shipping

Dry ice offers several advantages over traditional refrigeration methods, making it a preferred choice for shipping perishables.

Effective Refrigerant Properties

Dry ice remains cold for extended periods without leaving moisture, reducing the risk of spoilage and product damage. According to the Environmental Protection Agency (EPA), dry ice can maintain temperatures below freezing for up to 18 hours in a well-insulated container.

Environmentally Friendly

As a byproduct of industrial processes, dry ice is a more sustainable option compared to electric refrigerants. Its sublimation process leaves no residue, minimizing environmental impact.

Safety Guidelines for Handling Dry Ice

While dry ice is effective for shipping, it must be handled with care to ensure safety for both handlers and recipients.

Proper Handling Techniques

Dry ice is extremely cold and can cause frostbite upon direct contact with skin. Always wear protective gloves or use tongs when handling dry ice to prevent injuries.

Ventilation Requirements

As dry ice sublimates, it releases carbon dioxide gas, which can accumulate in enclosed spaces. It is crucial to ensure proper ventilation in shipping containers to prevent the buildup of CO2, which can pose health risks.

Appropriate Packaging

Use sturdy, insulated containers with secure lids to contain dry ice and perishable items. Avoid airtight packaging to allow gas escape, reducing the risk of pressure buildup.

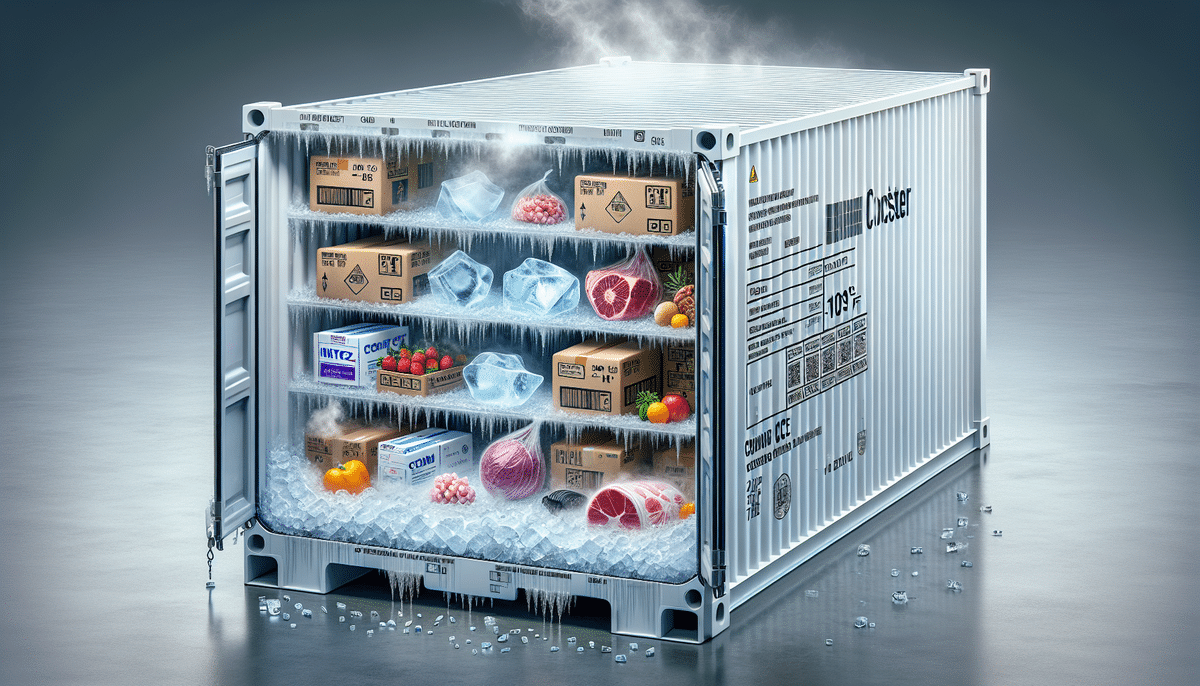

Best Practices for Packaging with Dry Ice

Effective packaging strategies are essential for maximizing the efficiency of dry ice in maintaining product integrity during shipping.

Choosing the Right Container

Select insulated containers that are appropriately sized to accommodate both dry ice and the perishables being shipped. Containers with thick walls and tight-fitting lids provide optimal insulation.

Calculating Dry Ice Quantity

The amount of dry ice required depends on the duration of the shipment and the quantity of perishable goods. A general guideline is to use 5 to 10 pounds of dry ice per 24 hours of shipping time for every 100 pounds of product. Adjustments may be necessary based on specific shipping conditions.

Layering Techniques

Distribute dry ice evenly within the container to ensure consistent cooling. Placing dry ice on top of the products allows cold air to sink and circulate effectively around the items.

Tips for Shipping Specific Perishables

Different types of perishables require tailored approaches to ensure their safe transport using dry ice.

Shipping Meat with Dry Ice

Use a High-Quality Cooler

Invest in a premium cooler that maintains consistent temperatures. According to the USDA Food Safety and Inspection Service, the cooler should consistently keep meat below 40°F (4°C).

Select Reliable Dry Ice Suppliers

Choose suppliers who provide high-quality dry ice with a consistent sublimation rate. Reliable suppliers ensure timely delivery and proper packaging of dry ice.

Freeze Meat Before Shipping

Deep-freeze meat before packaging to maintain low temperatures longer during transit. Ensure that meat is thoroughly frozen to maximize preservation.

Sufficient Dry Ice Quantity

Calculate and use enough dry ice to last the entire shipping period. For longer shipments, consider using multiple packages of dry ice distributed evenly within the container.

Shipping Fruits and Vegetables

For shipping fruits and vegetables, use breathable packaging to prevent moisture buildup. Incorporate moisture-absorbing materials or vents to maintain optimal humidity levels.

Shipping Pharmaceuticals

Pharmaceuticals often require precise temperature control. Utilize data loggers to monitor temperatures and ensure compliance with regulatory standards during shipping.

Regulations and Compliance

Adhering to regulations is essential when shipping dry ice to ensure safety and avoid legal issues.

Shipping Regulations for Dry Ice

Dry ice is classified as a hazardous material by the Federal Aviation Administration (FAA) and the Pipeline and Hazardous Materials Safety Administration (PHMSA). Compliance with their guidelines is mandatory for domestic and international shipments.

Labeling and Documentation

Proper labeling, including the “Dry Ice” hazard label, is required on all packages containing dry ice. Additionally, documentation specifying the quantity of dry ice must accompany shipments to inform carriers and handlers.

Conclusion

Shipping perishables with dry ice is an effective method to ensure products remain fresh and safe during transit. By understanding how dry ice works, adhering to safety guidelines, employing best packaging practices, and complying with regulations, businesses can reliably deliver high-quality products to their customers. Whether transporting meat, produce, or pharmaceuticals, dry ice offers a dependable solution for maintaining product integrity throughout the shipping process.