Creating an Effective Inventory Management Plan

As a business owner, one of the key factors that can make or break your success is effective inventory management. Keeping track of your inventory levels, understanding your needs and requirements, and mitigating potential risks are essential for smooth operations. In this article, we will dive into the intricacies of inventory management, covering various topics from conducting a thorough inventory audit to implementing an efficient tracking system.

Why Inventory Management Is Important for Your Business

Inventory management is vital for any business, regardless of its size or industry. Proper management ensures that you have the right products on hand at the right time, ultimately leading to increased sales and customer satisfaction. According to a 2023 industry report, businesses with optimized inventory management see up to a 20% increase in profitability.

Effective inventory management can also help you identify areas where you can reduce costs, streamline operations, and improve overall profitability. Moreover, it helps you avoid stockouts and overstocking, both of which can have negative impacts on your business. Stockouts can lead to lost sales and dissatisfied customers, while overstocking ties up your capital and increases the risk of spoilage or obsolescence. By tracking your inventory levels and forecasting demand, you can maintain optimal stock levels and avoid these costly issues.

Understanding Your Inventory Needs and Requirements

Before developing an inventory management plan, it's crucial to analyze your business's unique needs and requirements. Understanding your inventory levels, sales trends, and customer demand patterns helps determine what items to stock, how much inventory to order, and when to reorder.

- Seasonality: If your business experiences seasonal demand fluctuations, adjust your inventory accordingly. For example, a clothing store may need to stock more winter apparel in the fall.

- Shelf Life: For businesses dealing with perishable items like food or beauty products, monitor expiration dates to avoid waste and minimize costs.

According to the Shelf Life Analysis Study 2023, businesses that actively manage shelf life reduce waste by up to 15%.

Conducting a Thorough Inventory Audit

Conducting an inventory audit is an essential step in developing an effective inventory management plan. It helps you identify current inventory levels, detect discrepancies, and uncover potential areas for improvement. During an audit, focus on factors such as stock accuracy, item age, and storage conditions.

- Labeling and Categorization: Ensure all items are properly labeled and categorized to facilitate easy identification and location.

- Regular Updates: Continuously update your inventory records to reflect changes in stock levels or item information.

- Technology Integration: Utilize inventory management software to automate the audit process, enhancing speed and accuracy.

Implementing technologies like inventory management software can provide valuable insights into inventory trends and help identify areas for improvement.

Identifying Potential Risks and Challenges in Your Inventory Management Plan

Effective inventory management involves recognizing and mitigating potential risks and challenges. These include:

- Seasonal Fluctuations: Variations in demand during different seasons can impact inventory levels.

- Supply Chain Disruptions: Delays or disruptions in the supply chain can affect your ability to maintain optimal inventory levels.

- Overstocking and Understocking: Maintaining a balance between too much and too little inventory is crucial to avoid increased costs or lost sales.

Developing a contingency plan can help mitigate these risks. According to the Supply Chain Resilience Report 2023, businesses with robust contingency plans experience 30% fewer disruptions.

Choosing the Right Inventory Management Software for Your Business Needs

Investing in the right inventory management software is crucial for streamlining operations and ensuring efficient inventory control. When selecting software, consider the following factors:

- Scalability: Choose software that can grow with your business, accommodating increasing inventory and more complex operations.

- Integration: Ensure the software can integrate seamlessly with other systems such as accounting, sales, and procurement to facilitate a unified workflow.

Popular options include ShipScience Pro and ShipScience Lite, both offering robust features tailored to different business needs.

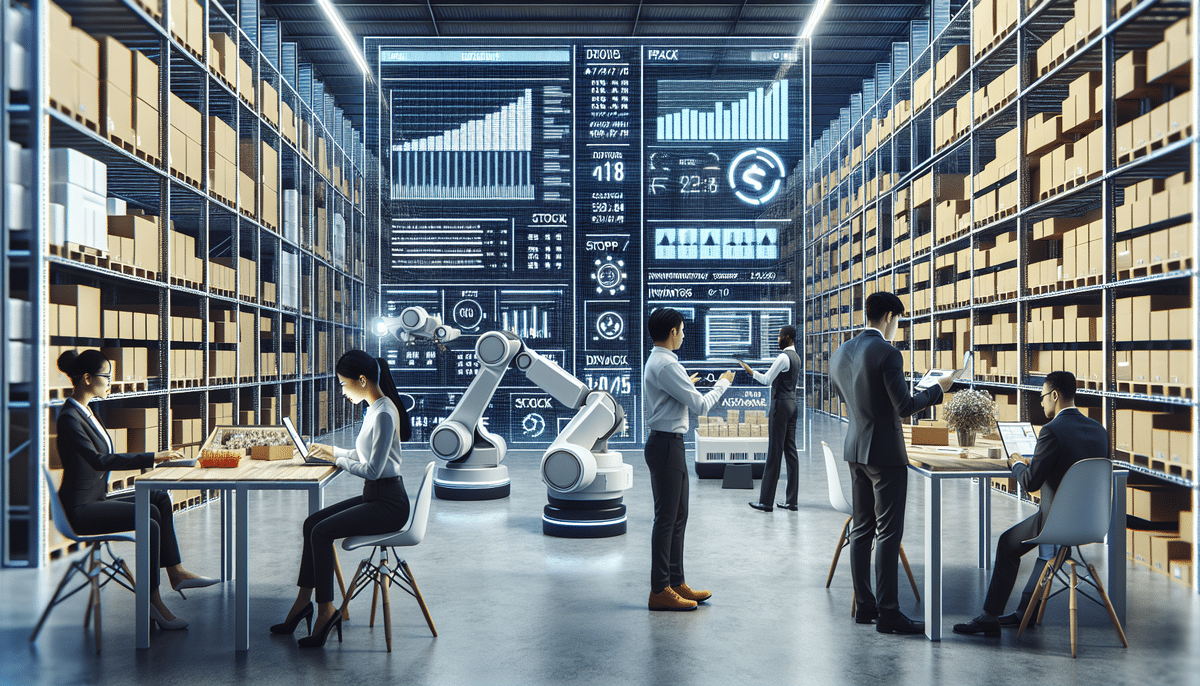

Implementing an Efficient Inventory Tracking System

Having an efficient inventory tracking system is critical for maintaining accurate inventory levels, reducing waste, and minimizing the risk of stockouts. Your tracking system should be integrated with your inventory management software, enabling real-time tracking, automated reordering, and performance analysis.

- Receiving and Storing Procedures: Establish clear procedures for receiving and storing inventory, including assigning unique identifiers to each item and labeling storage locations.

- Regular Physical Counts: Conduct regular physical inventory counts to ensure data accuracy and identify discrepancies.

Technologies such as barcode scanners and RFID tags can enhance the accuracy and efficiency of your inventory tracking system.

Setting Up an Effective Reorder Point and Safety Stock Levels

The reorder point and safety stock levels are critical components of your inventory management plan. The reorder point is the inventory level at which you need to reorder a particular item, while the safety stock acts as a buffer against unexpected demand fluctuations. Properly setting these levels helps optimize inventory and prevent frequent stockouts.

- Lead Time: Consider the time it takes to replenish inventory once an order is placed.

- Demand Variability: Analyze fluctuations in customer demand to set appropriate safety stock levels.

- Supplier Reliability: Evaluate your suppliers' reliability to account for potential delays or errors in the supply chain.

Regularly reviewing and adjusting your reorder points and safety stock levels ensures your inventory management plan remains effective and efficient.

Managing Your Inventory Costs and Budgets

Managing inventory costs and budgets is essential for maintaining profitability. Establishing a budget, setting cost-reduction targets, and continuously monitoring inventory levels are key strategies.

- Just-In-Time (JIT) Inventory: Implementing a JIT system involves ordering inventory only as needed, reducing storage and handling costs.

- Supplier Negotiations: Regularly review supplier agreements to negotiate better prices or terms, enhancing cost efficiency.

According to the Cost Management Guide 2023, businesses that adopt JIT inventory systems can reduce inventory holding costs by up to 25%.

Integrating Your Inventory Management Plan with Other Business Processes

Effective inventory management should be integrated with other business processes such as sales forecasting, production planning, and procurement. This integration streamlines operations, improves inventory accuracy, and reduces the risk of stockouts and overstocking.

- Sales Forecasting: Utilize historical sales data to predict future demand, informing how much inventory to order and when.

- Production Planning: Align production schedules with inventory levels to avoid overproduction and excess inventory.

Integrating these processes fosters a cohesive operational strategy, enhancing overall business efficiency.

Analyzing Performance Metrics to Improve Your Inventory Management Plan

Closely monitoring performance metrics such as inventory turnover rate, order fulfillment time, and stock accuracy can help identify weaknesses and uncover opportunities for improvement in your inventory management plan.

- Carrying Cost of Inventory: Calculate the expenses associated with storing and maintaining inventory, including rent, utilities, insurance, and labor costs.

- Inventory Turnover Rate: Measure how frequently inventory is sold and replaced over a specific period.

By regularly reviewing these metrics, you can determine optimal inventory levels, reduce carrying costs, and enhance overall profitability.

Training Employees to Effectively Manage and Maintain the Inventory System

Effective inventory management relies on a skilled and motivated workforce. It's essential to train employees on managing and maintaining the inventory system, covering areas such as data entry, inventory tracking, and order management.

- Comprehensive Training Programs: Develop training programs that cover all aspects of the inventory system.

- Continuous Education: Provide ongoing training to keep employees updated on the latest inventory management practices and software updates.

Well-trained employees contribute to higher inventory accuracy and more efficient operations.

Best Practices for Successful Inventory Management

Implementing best practices in inventory management can lead to higher accuracy, reduced waste, and improved customer satisfaction. Key best practices include:

- Reducing Safety Stock Levels: Optimize safety stock to balance between meeting demand and minimizing holding costs.

- Optimizing Stocking Levels: Regularly analyze sales data to adjust stocking levels based on demand trends.

- Streamlining Operations: Simplify inventory processes to enhance efficiency and reduce the potential for errors.

Adhering to these best practices ensures your inventory management system operates smoothly and effectively.

Common Mistakes to Avoid in Inventory Management

Avoiding common mistakes can significantly enhance your inventory management effectiveness. Common pitfalls include:

- Misinterpreting Sales Data: Ensure accurate analysis of sales data to inform inventory decisions.

- Failing to Prioritize Inventory Management: Recognize inventory management as a critical component of your business strategy.

- Overlooking Seasonal Demand Fluctuations: Adjust inventory levels in anticipation of seasonal changes in demand.

By being aware of these mistakes, you can implement strategies to prevent them, maintaining smooth operations and optimal inventory levels.

Future Trends in Inventory Management Technology and Strategies

Inventory management technology and strategies are continually evolving. Staying updated with these trends can provide a competitive edge. Emerging trends include:

- Internet of Things (IoT): IoT devices facilitate real-time tracking and monitoring of inventory, enhancing accuracy and efficiency.

- Big Data Analytics: Leveraging big data helps in predicting demand patterns and optimizing inventory levels.

- Automated Replenishment Systems: Automation streamlines the reordering process, reducing the likelihood of stockouts and overstocking.

Embracing these trends can lead to more sophisticated and effective inventory management practices.

In conclusion, effective inventory management requires careful planning, continuous monitoring, and the implementation of best practices. By following these steps, you can improve your operations, reduce costs, and increase customer satisfaction. Take the time to evaluate your inventory management plan and implement the necessary measures to optimize your inventory levels.