CubiScan Dimensioning Systems vs. NTEP Certified Scales with Integrated Dimensioning

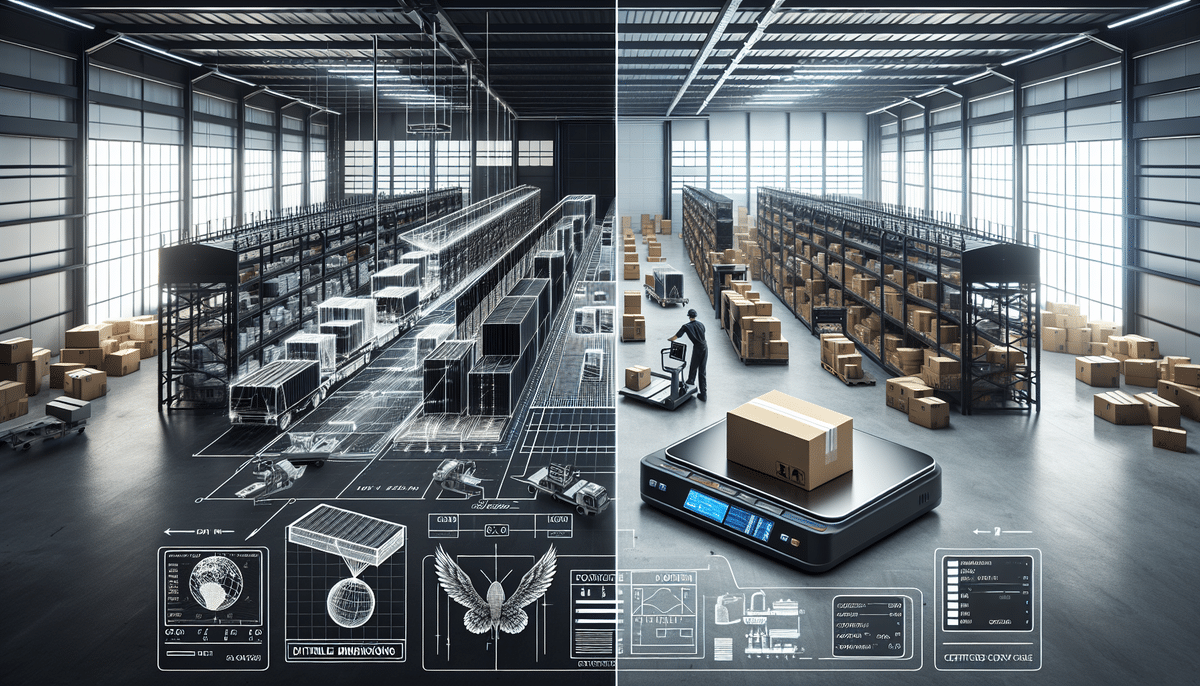

Accurate package measurement is crucial for businesses handling large volumes of shipments. It ensures customers are billed correctly for shipping and positively impacts your bottom line. Among the various dimensional scanning systems available, CubiScan and NTEP (National Type Evaluation Program) certified scales with integrated dimensioning stand out. This comprehensive comparison explores their differences, benefits, and drawbacks to help you choose the best system for your business.

Understanding CubiScan Dimensioning Systems

CubiScan is a leading provider of cubing and weighing systems designed to integrate seamlessly with warehouse management software. Utilizing advanced lasers, cameras, and sensors, CubiScan systems accurately measure the dimensions and weight of packages. These systems are widely used across industries such as e-commerce, logistics, and healthcare, automating the dimensioning process to save time, reduce costs, and enhance accuracy.

One key advantage of CubiScan systems is their compatibility with existing warehouse management software, enabling businesses to incorporate dimensioning and weighing data without additional software or hardware investments. This integration streamlines operations and boosts overall efficiency.

Beyond warehouses, CubiScan systems are instrumental in transportation and logistics. By precisely measuring package dimensions and weight, these systems optimize shipping processes, reduce costs, and ensure accurate classification and billing, minimizing the risk of errors and disputes.

Exploring NTEP Certified Scales with Integrated Dimensioning

NTEP certified scales are designed to meet national standards of accuracy and performance for commercial measuring devices. Primarily used in the shipping industry, these scales accurately measure package weight and often integrate dimensioning technology to provide a comprehensive shipment measurement solution.

The dimensioning technology in NTEP certified scales measures package dimensions—length, width, and height—and combines this data with weight measurements to calculate the dimensional weight of a package. This is critical for shipping companies, as they typically charge based on the higher of the actual or dimensional weight. Using NTEP certified scales with integrated dimensioning ensures accurate measurements and billing, leading to cost savings and enhanced customer satisfaction.

Key Differences Between CubiScan and NTEP Scales

Technology and Measurement Accuracy

Although both CubiScan and NTEP scales measure package dimensions, they employ different technologies. CubiScan systems use lasers, cameras, and sensors for precise measurement of both dimensions and weight. In contrast, NTEP scales focus primarily on weight measurement and require additional technology for dimensioning. This makes CubiScan systems generally more accurate, especially with irregularly shaped or unevenly weighted packages.

Industry Applications

CubiScan systems are designed primarily for warehouse and logistics environments, optimizing storage and shipping processes, and calculating shipping costs based on accurate measurements. NTEP scales, however, are typically used for legal trade measurements, such as weighing products sold by weight. Selecting the appropriate system depends on your specific business requirements.

Cost and Investment

CubiScan systems may entail higher upfront costs due to their advanced technology, but their accuracy and efficiency can lead to long-term savings. On the other hand, NTEP scales are more affordable, making them a practical choice for smaller businesses or those with limited budgets.

Accuracy Comparison: CubiScan vs. NTEP Scales

CubiScan systems offer superior accuracy in measuring package dimensions due to their advanced technology, ensuring precise and consistent measurements. Studies have shown that automated dimensioning systems like CubiScan can reduce measurement errors by up to 95% compared to manual methods (Source).

In contrast, NTEP scales may face accuracy challenges related to package shape and weight distribution. However, NTEP scales remain indispensable in industries like agriculture and manufacturing, where accurate weight measurement is paramount.

While CubiScan systems may have higher initial costs, their accuracy and efficiency can lead to long-term savings, making them ideal for businesses with substantial shipment volumes and accuracy requirements. NTEP scales, being more affordable, are a practical choice for smaller businesses or those with less critical dimensional accuracy needs.

Benefits of Using CubiScan Dimensioning Systems for Your Business

Implementing CubiScan systems offers numerous advantages:

- Higher Accuracy: Superior precision in measuring package dimensions compared to NTEP scales.

- Efficiency: Automates the dimensioning process for faster shipment processing.

- Cost-Effective: Reduces labor costs and minimizes errors that could lead to additional expenses.

- Compatibility: Integrates seamlessly with various warehouse management software systems.

Additionally, CubiScan systems capture and store detailed data on package dimensions and weight, aiding in optimizing warehouse space, improving inventory management, and identifying shipping trends. Compliance with shipping regulations is also enhanced, helping businesses avoid costly penalties by ensuring accurate measurements and adherence to carrier restrictions.

Advantages of NTEP Certified Scales with Integrated Dimensioning

NTEP certified scales with integrated dimensioning offer several benefits:

- Affordability: Generally more cost-effective than CubiScan systems.

- Industry Suitability: Ideal for businesses that do not require high levels of dimensional accuracy.

- Ease of Use: User-friendly with minimal training requirements.

These scales also streamline operations by combining weighing and dimensioning into a single process, saving time and enhancing efficiency—particularly beneficial for businesses handling large volumes of shipments.

However, their suitability is limited for businesses needing high dimensional accuracy, where CubiScan systems would be more appropriate.

Choosing Between CubiScan and NTEP Scales: Key Considerations

Selecting the right system depends on your business's specific needs. Consider the following factors:

- Accuracy Requirements: Determine the level of precision needed for your shipments.

- Package Characteristics: Assess the shape and weight distribution of your packages.

- Automation and Integration: Evaluate the extent of automation and software integration required.

- Budget: Consider your financial constraints and the overall cost-effectiveness of each system.

- Support and Maintenance: Ensure access to reliable technical support and maintenance services.

Additionally, consider the support and maintenance services offered. CubiScan systems are known for their reliability and low maintenance needs, whereas NTEP scales may require more frequent calibration and upkeep. Ensuring access to technical support and training is also crucial for the effective use and maintenance of the selected system.

Real-World Applications: CubiScan and NTEP Scales in Action

Major companies like Amazon, FedEx, and UPS utilize CubiScan systems to enhance dimensional accuracy, speed, and efficiency in their shipping operations. These systems enable these companies to handle millions of packages with high precision, reducing costs and improving customer satisfaction.

On the other hand, smaller operations, such as independent freight forwarders or small e-commerce sellers, often adopt NTEP scales with integrated dimensioning for their efficiency and cost-effectiveness. These businesses benefit from the streamlined weighing and dimensioning process without the need for significant capital investment.

Essential Factors When Selecting a Dimensioning System

When choosing a dimensioning system, consider the following aspects:

- Accuracy: Ensure the system meets your precision requirements.

- Speed and Efficiency: Opt for systems that enhance processing speed.

- System Compatibility: Verify integration capabilities with your existing software.

- Cost-Effectiveness: Balance initial costs with long-term benefits.

- Automation and Integration: Assess the level of automation and ease of integration.

- Customer Support: Evaluate the quality of customer support and after-sales service.

Cost Analysis: CubiScan vs. NTEP Scales

CubiScan systems typically come at a higher price point than NTEP scales with integrated dimensioning. The cost of CubiScan systems varies based on the model and additional features required. Conversely, NTEP scales are more affordable, making them suitable for businesses with lower dimensional accuracy needs or smaller shipment volumes.

Investing in CubiScan can offer greater accuracy and efficiency, potentially offsetting the higher initial investment through long-term savings and improved operational performance. A study by Statista indicates that automated dimensioning systems can reduce operational costs by up to 30% over five years.

Best Practices for Implementing a Dimensioning System

To successfully integrate a dimensioning system into your warehouse management system, follow these best practices:

- Optimize Warehouse Space: Ensure adequate power supply, wiring, and network infrastructure for the system.

- Employee Training: Provide comprehensive training for employees on system usage and maintenance.

- Effective Data Management: Establish a management system that integrates measured data with existing software and processes.

- Regular Evaluation: Regularly evaluate and audit the system to maintain efficiency and accuracy.

Avoiding Common Integration Mistakes

Ensure a smooth integration by avoiding these common pitfalls:

- Inadequate Training: Failing to provide adequate training for employees on system usage and maintenance.

- Neglecting Maintenance: Neglecting regular calibration and maintenance, leading to inaccurate measurements.

- Poor Space Optimization: Not optimizing warehouse space or workflow to support the new system.

Future Trends and Advancements in Dimensioning Systems

Technological advancements are transforming the logistics industry, including dimensioning systems. Key trends and advancements include:

- Increased Automation: Enhanced integration with existing software and AI algorithms for smarter operations.

- 3D Imaging and Scanning: Improved accuracy and reduced need for multiple scanning points.

- IoT Integration: IoT-enabled tracking and monitoring of warehouse and shipping operations.

- Cloud-Based Solutions: Remote management and data access through cloud technologies.

Conclusion: Choosing the Right Dimensioning System for Your Business

Deciding between CubiScan and NTEP scales with integrated dimensioning hinges on your business's specific needs, including accuracy, shipment volume, automation requirements, and budget constraints. CubiScan systems offer higher accuracy, efficiency, and broader software compatibility, making them ideal for larger operations with stringent accuracy demands. Conversely, NTEP scales provide a cost-effective solution suitable for smaller businesses or those with less critical dimensional accuracy requirements.

Carefully assess your business requirements to choose the system that best aligns with your operational goals and financial parameters. Implementing the right dimensioning system can lead to significant improvements in accuracy, efficiency, and cost savings, ultimately enhancing your business's competitiveness in the market.