Introduction to Dimensioning Systems

In the rapidly evolving landscape of logistics and supply chain management, accurate dimensioning of packages is essential for optimizing shipping costs and enhancing operational efficiency. Dimensioning systems calculate the dimensional weight of goods, a critical factor since shipping companies often charge based on both the weight and size of a package. By leveraging advanced sensors and software, these systems measure the height, width, and depth of packages to determine their dimensional weight, ensuring accurate billing and reducing the likelihood of additional charges.

The rise of e-commerce has significantly increased the demand for precise dimensioning solutions. As online retailers strive to offer competitive shipping rates and improve customer satisfaction, investing in reliable dimensioning technology has become a necessity. Moreover, accurate dimensioning contributes to sustainability efforts by minimizing the use of oversized packaging materials, thus reducing waste and lowering shipping costs.

Overview of CubiScan Dimensioning Systems

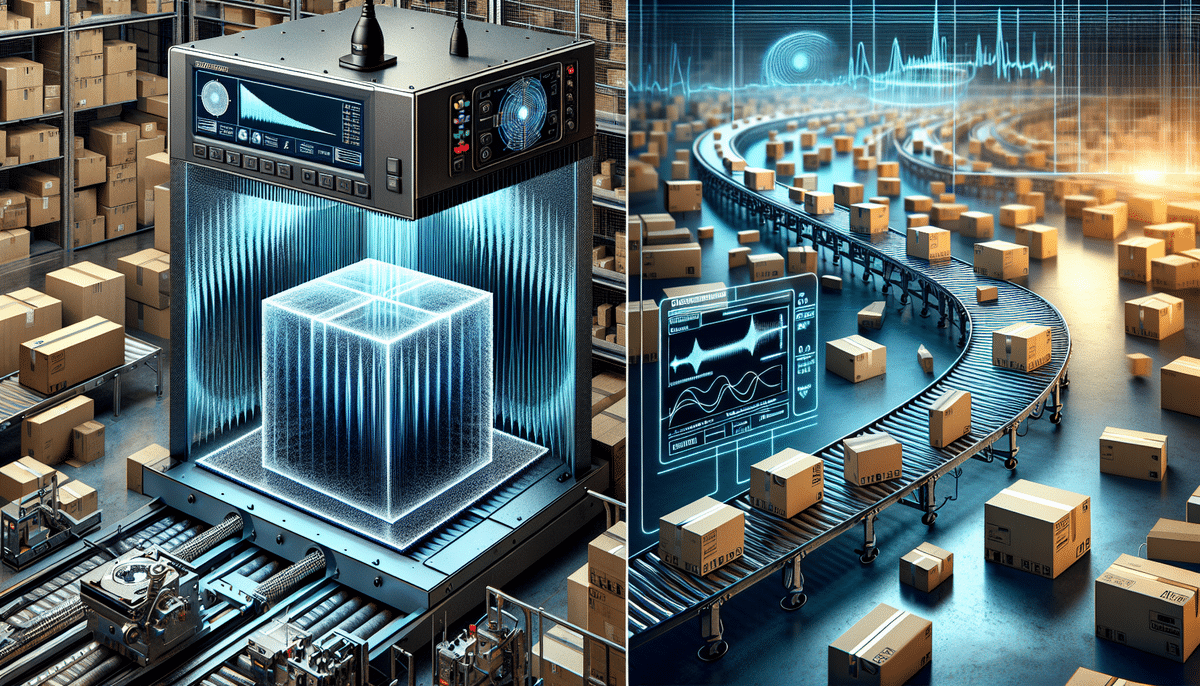

CubiScan offers a range of dimensioning systems tailored for warehouses, distribution centers, and logistics companies. Renowned for their reliability and accuracy, CubiScan systems utilize ultrasonic and laser technologies to measure package dimensions efficiently.

CubiScan 100

The CubiScan 100 employs ultrasonic technology to capture package dimensions. Ultrasonic waves are emitted towards the package and reflected back to sensors, allowing the system to calculate precise measurements. This model is praised for its ease of use and integration capabilities with existing warehouse management systems.

CubiScan 125 and 150

Building on the foundation of the CubiScan 100, the CubiScan 125 and CubiScan 150 models incorporate advanced laser technology. This enhancement provides even higher accuracy rates, making them suitable for environments where precision is paramount. These models are designed to streamline shipping and inventory management processes, saving time and reducing human error.

Overview of Rice Lake iDimension Series

Rice Lake iDimension Series is another prominent player in the dimensioning systems market, offering solutions that leverage image processing technology to measure package dimensions accurately.

iDimension 100

The iDimension 100 is a compact and portable system ideal for smaller warehouses or facilities with limited space. It uses image processing to capture and calculate package dimensions swiftly, making it a versatile choice for businesses with varying shipment volumes.

iDimension 200

The iDimension 200 is designed for high-volume operations, capable of handling packages up to 36 inches in length and 100 pounds in weight. Its robust design and advanced software integration make it suitable for large distribution centers that require efficient and scalable dimensioning solutions.

Rice Lake's systems are known for their seamless integration with various shipping and warehouse management software, enhancing overall operational efficiency and reducing the need for manual data entry.

Comparative Analysis: CubiScan vs. Rice Lake iDimension Series

Technology Utilized

While both CubiScan and Rice Lake iDimension Series provide reliable dimensioning solutions, they employ different technologies. CubiScan primarily uses ultrasonic and laser technologies, whereas Rice Lake relies on image processing. This fundamental difference affects their accuracy, speed, and suitability for various operational scales.

Volume Handling

CubiScan systems are versatile, catering to both low and high-volume shipping tasks. In contrast, Rice Lake iDimension Series is specifically engineered for high-volume processing, making it ideal for large-scale operations.

System Integration

Both systems offer integration capabilities, but Rice Lake iDimension Series supports more complex courier and shipping tasks. CubiScan integrates seamlessly with warehouse management systems and barcode systems, offering flexibility for various business needs.

Accuracy

Rice Lake iDimension Series boasts a higher precision of ±0.2 inches compared to CubiScan's ±0.5 inches. This enhanced accuracy is crucial for businesses that require meticulous dimensional measurements to optimize shipping costs.

Cost Considerations

CubiScan systems are generally more cost-effective, with models like the CubiScan 100 priced around $8,000. In contrast, Rice Lake iDimension Series starts at approximately $15,000. Businesses must weigh these costs against their specific needs and the potential return on investment.

Cost Comparison

When evaluating the financial investment required for dimensioning systems, it's essential to consider both initial costs and long-term benefits. CubiScan offers more budget-friendly options, making it accessible for small to medium-sized businesses. For instance, the CubiScan 100 is priced around $8,000, providing a balance between cost and functionality.

On the other hand, Rice Lake iDimension Series starts at approximately $15,000, reflecting its advanced features and higher accuracy levels. While the initial investment is higher, the increased precision and capacity for handling large volumes can result in significant cost savings over time by reducing shipping errors and optimizing packaging materials.

It's important to consider not just the upfront costs but also the potential for increased efficiency and reduced operational expenses when making a decision.

User Experiences and Reviews

CubiScan User Feedback

Customers of CubiScan dimensioning systems frequently praise the devices for their accuracy and ease of integration with existing systems. Users highlight the compact design and user-friendly interface as significant advantages. However, some have noted challenges when measuring heavy or bulky packages and reflective surfaces, which can affect accuracy.

Rice Lake iDimension Series User Feedback

Rice Lake iDimension Series users commend the systems for their reliability and high precision. The ability to handle large volumes efficiently is a common positive remark. Nonetheless, some users find the systems more complex to operate and require additional training, particularly when dealing with irregularly shaped packages.

Overall, both systems receive favorable reviews, with the choice often depending on the specific operational needs and scale of the business.

Choosing the Right Dimensioning System for Your Business

Selecting the appropriate dimensioning system involves assessing various factors tailored to your business operations:

- Shipment Volume: High-volume operations may benefit more from the Rice Lake iDimension Series, while low to moderate volumes might be better served by CubiScan systems.

- Package Types: If you frequently handle irregularly shaped or fragile packages, consider the measurement technology that best accommodates these variations.

- Space Availability: Ensure that the chosen system fits within your available warehouse space.

- Budget: Factor in both the initial investment and ongoing maintenance costs.

- Technical Expertise: Assess the technical skills of your team to operate and maintain the system effectively.

Conducting a thorough needs analysis and possibly consulting with experts can help in making an informed decision that aligns with your business objectives.

Future Trends in Dimensioning Technology

The dimensioning technology landscape continues to evolve, driven by advancements in sensor technology, artificial intelligence, and automation. Key trends to watch include:

- Enhanced Automation: Increased automation will reduce the need for manual intervention, speeding up the dimensioning process.

- Artificial Intelligence Integration: AI and machine learning algorithms will improve measurement accuracy and predictive maintenance.

- IoT Connectivity: Integration with the Internet of Things (IoT) will enable better data sharing and real-time monitoring across supply chain networks.

- Mobile and Cloud Solutions: Mobile integration and cloud-based data management will offer greater flexibility and accessibility for businesses.

- Sustainability Focus: Future systems will emphasize energy efficiency and the reduction of material waste in packaging processes.

Staying abreast of these trends will ensure that businesses can adopt the most effective and sustainable dimensioning solutions, maintaining a competitive edge in the logistics industry.

Conclusion

Both CubiScan and Rice Lake iDimension Series offer robust dimensioning systems tailored to different business needs. CubiScan provides cost-effective and versatile solutions suitable for a range of shipment volumes, while Rice Lake iDimension Series excels in high-volume, high-precision environments. When choosing between the two, businesses should consider factors such as volume, package types, space, budget, and technical requirements. Accurate dimensional data is increasingly vital in optimizing logistics operations, reducing costs, and enhancing customer satisfaction. Investing in the right dimensioning system not only streamlines shipping processes but also contributes to overall business efficiency and sustainability.