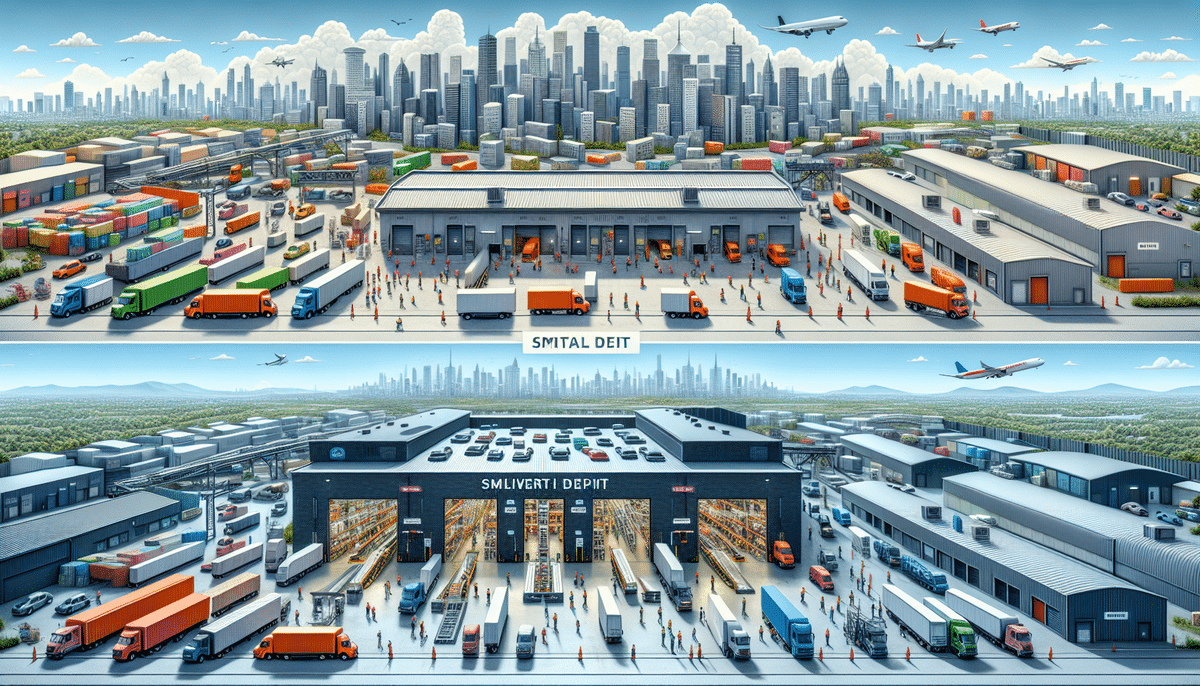

Depot vs Warehouse: Understanding the Key Differences

As businesses grow and expand their operations, the need for efficient storage solutions becomes paramount. Depots and warehouses are two critical types of storage facilities that play distinct roles in managing inventory and ensuring smooth supply chain operations. While the terms “depot” and “warehouse” are often used interchangeably, they serve different functions and offer unique features that cater to various business needs. This article delves into the concepts of depots and warehouses, highlighting their purposes, advantages, disadvantages, and the factors businesses should consider when choosing between them.

Defining Depots and Warehouses

What is a Depot?

A depot is a storage facility primarily used for the short-term storage of goods and supplies. Depots are strategically located close to delivery destinations to facilitate the rapid distribution and delivery of products to customers. They are typically smaller than warehouses and are designed to handle smaller inventories, making them ideal for industries that require quick and efficient delivery.

Depots are commonly utilized in the transportation industry for storing goods being transported by trucks or trains. In the construction sector, depots store materials and equipment near construction sites to ensure timely availability. Depots can be owned and operated by the company or leased from third-party providers, providing flexibility in logistics operations.

What is a Warehouse?

A warehouse is a large-scale storage facility designed to store substantial quantities of goods over extended periods. Unlike depots, warehouses are usually located away from city centers and are equipped to handle complex inventories, including individual parts, components, and finished products. Modern warehouses often feature advanced infrastructure such as loading docks, conveyor systems, and automated storage and retrieval systems (AS/RS).

Warehouses play a crucial role in various industries by providing a centralized location for product storage, inventory management, and distribution. They enable businesses to scale their operations, optimize inventory levels, and reduce overall operational costs. The enhanced security features of warehouses, including surveillance cameras and access control systems, make them suitable for storing high-value or sensitive products.

Roles in Supply Chain Management

Depots in Supply Chain

Depots are integral to supply chain management by offering short-term storage solutions that reduce transportation costs and lead times. By positioning depots closer to customers, businesses can ensure faster delivery and better inventory management. Depots serve as hubs for coordinating the flow of goods, consolidating shipments from multiple suppliers, and providing value-added services such as packaging and labeling.

According to a Supply Chain Digital report, efficient depot management can lead to a significant reduction in delivery times, enhancing customer satisfaction and operational efficiency.

Warehouses in Supply Chain

Warehouses are pivotal in maintaining the balance between supply and demand by storing products until they are needed. They enable businesses to manage large inventories, track product movement, and ensure that goods are available to meet customer demand without delays. Warehouses also support various logistics functions, including receiving, sorting, and processing goods, which are essential for maintaining an efficient supply chain.

The American Shipping & Export Association highlights that effective warehouse management systems (WMS) can improve inventory accuracy by up to 99%, thereby reducing costs associated with overstocking and stockouts.

Advantages and Disadvantages

Advantages of Depots

- Proximity to Customers: Depots are located near delivery destinations, ensuring faster delivery times and improved customer satisfaction.

- Cost-Effective: Smaller size and minimal infrastructure requirements make depots a more affordable option for short-term storage.

- Flexibility: Depots can be easily scaled up or down based on demand, providing businesses with adaptable storage solutions.

- Reduced Transportation Costs: Strategic placement of depots minimizes the distance traveled by delivery vehicles, lowering fuel costs and carbon emissions.

Disadvantages of Depots

- Limited Storage Capacity: Depots are not suitable for long-term or large-scale storage needs.

- Security Concerns: Depots may have less stringent security measures compared to warehouses, increasing the risk of theft or damage.

- Short-Term Focus: Depots are designed for temporary storage, making them unsuitable for businesses requiring prolonged inventory holding.

Advantages of Warehouses

- Large Storage Capacity: Warehouses can accommodate vast inventories, making them ideal for businesses with extensive storage needs.

- Advanced Security: Enhanced security features protect high-value and sensitive products from theft and damage.

- Operational Efficiency: Automation and sophisticated inventory management systems streamline logistics operations and reduce errors.

- Long-Term Storage: Warehouses provide solutions for businesses needing to store products over extended periods.

Disadvantages of Warehouses

- Higher Costs: Larger size and advanced infrastructure result in higher operational and maintenance costs.

- Location Constraints: Warehouses are often located in remote areas, which can lead to increased transportation times and costs.

- Less Flexibility: Scaling warehouse operations can be more complex and costly compared to depots.

Cost-Effectiveness: Depots vs Warehouses

The choice between depots and warehouses in terms of cost-effectiveness depends on a business’s specific needs. Depots are generally more cost-effective for businesses requiring short-term storage and frequent deliveries due to their proximity to customers and lower infrastructure costs. In contrast, warehouses are more suitable for businesses with large inventories and long-term storage needs, despite the higher initial investment.

According to a Forbes article, implementing automation in warehouses can lead to a return on investment (ROI) of up to 20% through increased efficiency and reduced labor costs.

Technological Impacts on Depots and Warehouses

Technology in Depots

Depots are leveraging technologies such as real-time tracking systems and inventory management software to enhance operational efficiency. These technologies enable businesses to monitor inventory levels, track shipments in real-time, and optimize delivery routes, leading to reduced lead times and improved customer satisfaction.

Technology in Warehouses

Warehouses are at the forefront of adopting advanced technologies like automation, artificial intelligence (AI), and robotics. Automated storage and retrieval systems (AS/RS), conveyor systems, and AI-driven inventory management are transforming warehouse operations, increasing storage capacity, and improving material handling processes. These technologies not only enhance efficiency but also reduce operational costs and minimize human error.

The McKinsey & Company reports that AI integration in warehouse operations can increase productivity by up to 30% and significantly reduce operational costs.

Future Trends and Innovations

The future of depots and warehouses is being shaped by ongoing technological advancements and evolving business needs. Key trends include:

- Automation and Robotics: Continued integration of robotics and automated systems to enhance efficiency and accuracy in storage and retrieval operations.

- Artificial Intelligence: AI-driven analytics for predictive inventory management, demand forecasting, and optimization of supply chain processes.

- Sustainable Practices: Adoption of renewable energy sources, such as solar and wind power, and implementation of green building practices to reduce the environmental impact.

- Internet of Things (IoT): Enhanced connectivity through IoT devices for real-time monitoring, improved security, and optimized operations.

- Blockchain Technology: Improved transparency and traceability in supply chain operations through blockchain-based systems.

These innovations are expected to drive significant improvements in the efficiency, sustainability, and flexibility of both depots and warehouses, enabling businesses to meet the dynamic demands of the global market.

Choosing the Right Solution for Your Business

Deciding between a depot and a warehouse requires a thorough analysis of your business’s specific needs and operational requirements. Consider the following factors:

- Inventory Volume: Assess the quantity and types of products you need to store. Warehouses are suitable for large volumes, while depots are ideal for smaller, more frequent inventories.

- Storage Duration: Determine whether you need short-term or long-term storage solutions. Depots are better for temporary storage, whereas warehouses cater to prolonged storage needs.

- Location: Evaluate the importance of proximity to your customer base. Depots are advantageous for businesses requiring quick deliveries, while warehouses can be situated further away to leverage lower real estate costs.

- Budget: Consider the financial implications, including initial setup costs, operational expenses, and potential ROI. Depots generally have lower costs compared to warehouses.

- Security Requirements: Ensure that the storage solution meets the security needs of your products. Warehouses typically offer more advanced security features.

- Scalability: Assess the flexibility to scale operations based on demand. Depots offer greater flexibility for scaling up or down.

In some cases, a hybrid approach utilizing both depots and warehouses may provide the optimal balance between cost, efficiency, and scalability. This strategy allows businesses to leverage the strengths of both types of storage facilities, ensuring robust and flexible supply chain operations.

Real-Life Examples: Case Studies

Amazon: Leveraging Warehouses for Global Reach

Amazon utilizes a vast network of warehouses and fulfillment centers strategically located around the world to ensure prompt and efficient delivery of products to customers. Their advanced warehouse management systems and automation technologies enable Amazon to handle massive order volumes while maintaining high levels of accuracy and speed.

Walmart: Utilizing Depots for Efficient Distribution

Walmart employs depots to manage inventory and facilitate the timely delivery of products to its numerous retail stores. By positioning depots near key markets, Walmart reduces transportation distances, lowers fuel costs, and enhances delivery speed, ensuring that shelves are consistently stocked with a diverse range of products.

Implementing an Effective Storage Strategy

To maximize the benefits of depots and warehouses, businesses must develop and implement a comprehensive storage strategy. Key steps include:

- Needs Assessment: Conduct a thorough analysis of your inventory requirements, storage duration, and distribution needs.

- Location Planning: Select optimal locations for depots or warehouses based on proximity to customers, suppliers, and transportation networks.

- Technology Integration: Invest in modern inventory management systems, automation technologies, and security measures to enhance operational efficiency.

- Cost Management: Develop a budget that accounts for initial setup costs, ongoing operational expenses, and potential savings from optimized logistics.

- Performance Monitoring: Implement metrics and performance indicators to regularly evaluate the effectiveness of your storage strategy and make necessary adjustments.

Regular performance evaluations and strategic adjustments are essential to ensure that your depot or warehouse operations remain aligned with your business objectives and market demands.

Conclusion

Depots and warehouses are fundamental components of supply chain and logistics networks, each serving distinct purposes and offering unique advantages. Understanding the key differences between depots and warehouses, along with their respective roles in supply chain management, allows businesses to make informed decisions about their storage solutions. By carefully considering factors such as inventory volume, storage duration, location, budget, and security requirements, businesses can select the most cost-effective and efficient storage option that aligns with their operational goals. Additionally, embracing technological advancements and future trends will further enhance the efficiency and sustainability of depot and warehouse operations, ensuring long-term success in a competitive market.