As businesses grow and expand their operations, they often require additional storage facilities to manage their inventory and supplies. In such instances, depots and warehouses become essential. Although the terms "depot" and "warehouse" may seem interchangeable, they have different functions and features that set them apart from each other. In this article, we will examine the concepts of depots and warehouses, their purposes in supply chain and logistics, the pros and cons of using them, and other important factors that businesses must consider when deciding between the two.

Understanding the Concept of a Depot

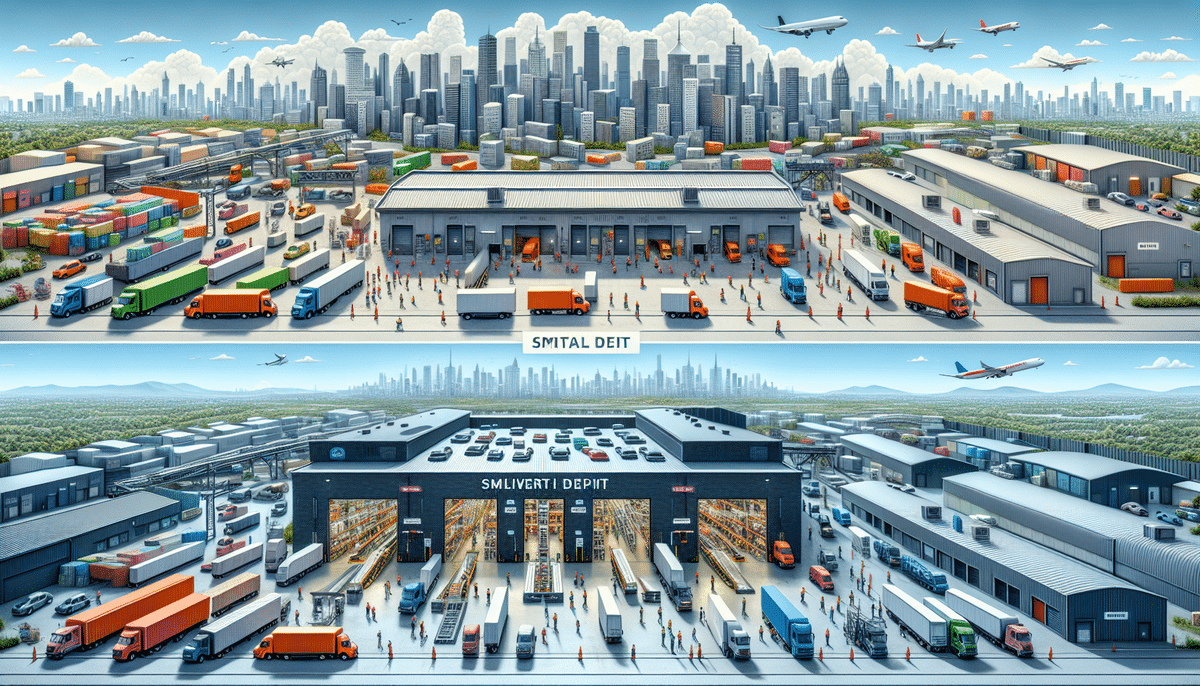

A depot is a storage facility that is primarily used for the short-term storage of goods and supplies. It is usually a temporary storage facility that is located close to the delivery destination. Depots are strategically located to enable a more efficient distribution and delivery of goods to customers. They are commonly used in industries where products need to be delivered quickly and efficiently. A depot is usually smaller than a warehouse and is designed to handle smaller inventories.

Depots are often used in the transportation industry, particularly for the storage of goods that are being transported by trucks or trains. They are also commonly used in the construction industry, where materials and equipment can be stored at a depot near the construction site. Depots can be owned and operated by the company that uses them, or they can be leased from a third-party provider. Regardless of ownership, depots play a crucial role in ensuring that goods are delivered to customers in a timely and efficient manner.

What is a Warehouse and How Does it Differ from a Depot?

A warehouse, on the other hand, is a large-scale storage facility that is designed to store large quantities of goods for extended periods. Warehouses are generally located away from the city center and are often used for storing a wide variety of goods, materials, and supplies. They are designed to handle complex inventories, such as individual parts, components, and finished products. Warehouses may also have additional features such as loading docks, conveyor systems, and automated storage and retrieval systems.

Depots, on the other hand, are smaller storage facilities that are typically located in urban areas. They are used for short-term storage of goods and materials, and are often used as a hub for transportation and distribution. Depots are designed to handle smaller inventories and are usually used for goods that are in transit or awaiting delivery to their final destination.

Another key difference between warehouses and depots is the level of security. Warehouses are often highly secure facilities, with features such as security cameras, access control systems, and 24-hour monitoring. Depots, on the other hand, may have less stringent security measures, as they are typically located in more populated areas and are used for shorter periods of time.

The Purpose of a Depot in Supply Chain Management

Depots play an essential role in supply chain management by providing short-term storage facilities for products and materials. They help to reduce transportation costs by enabling the efficient delivery of goods to customers. Depots also help to minimize lead times, reducing the time it takes for products to reach their final destination. This makes them an essential cog in the supply chain management process.

In addition to providing storage and reducing transportation costs, depots also serve as a hub for coordinating and managing the flow of goods in the supply chain. They can act as a central location for receiving and consolidating shipments from multiple suppliers, allowing for more efficient and cost-effective transportation. Depots can also provide value-added services such as packaging, labeling, and quality control inspections, further streamlining the supply chain process. Overall, depots are a critical component in ensuring the smooth and efficient operation of the supply chain.

The Role of a Warehouse in Logistics and Distribution

Warehouses are an integral part of logistics and distribution networks. They provide long-term storage for goods and materials, enabling businesses to store their products and manage their inventories more effectively. Warehouses also provide businesses with the ability to scale their operations, increase efficiencies, and reduce overall operational costs. They act as a central point for product distribution and delivery, reducing lead times and ensuring that customers receive their orders on time.

In addition to storage and distribution, warehouses also play a crucial role in the supply chain management process. They serve as a hub for receiving, sorting, and processing goods, allowing businesses to track inventory levels and monitor product movement. Warehouses also provide value-added services such as packaging, labeling, and assembly, which can help businesses streamline their operations and improve customer satisfaction. With the rise of e-commerce and online shopping, warehouses have become even more important in ensuring timely and efficient delivery of goods to customers.

Key Characteristics of a Depot and their Importance in Business Operations

Depots tend to be smaller facilities with limited storage capacity. They are typically located close to the delivery destination, allowing for faster and more efficient distribution of products. Depots are designed to be flexible and scalable, providing businesses with the ability to adjust their storage capacity as needed. They require fewer resources and infrastructure in comparison to larger warehouses, which makes them a cost-effective option for businesses seeking short-term storage solutions.

Another important characteristic of depots is their role in reducing transportation costs. By having multiple depots located strategically, businesses can reduce the distance traveled by their delivery vehicles, which in turn reduces fuel costs and carbon emissions. Depots also allow for better inventory management, as businesses can store products closer to their customers and reduce the risk of stockouts. Additionally, depots can serve as a hub for other business operations, such as packaging and labeling, which can further streamline the distribution process.

How Warehouses Play a Vital Role in the Product Delivery Process

Warehouses play a vital role in ensuring that products are delivered on time and in the right condition. They help to ensure that products are adequately protected from damage and deterioration, reducing the possibility of product defects and returns. Warehouses also enable businesses to keep track of their inventory levels, ensuring that they have sufficient stock on hand to meet customer demand.

In addition to these benefits, warehouses also provide a centralized location for product storage and distribution. This allows businesses to streamline their operations and reduce transportation costs by consolidating shipments. Warehouses can also offer value-added services such as product assembly, labeling, and packaging, which can further enhance the efficiency of the product delivery process.

Furthermore, warehouses can play a critical role in disaster recovery and business continuity planning. By storing products in a secure and protected environment, businesses can minimize the risk of loss or damage in the event of a natural disaster or other unforeseen event. This can help to ensure that products are still available to customers even in the face of unexpected disruptions to the supply chain.

Examining the Pros and Cons of Using Depots vs Warehouses

When deciding between using a depot or warehouse, businesses must consider several factors, including their inventory requirements, distribution networks, and shipping locations. Depots are an excellent option for businesses that need short-term storage facilities located close to their delivery destination. They are typically more affordable than warehouses, require minimal infrastructure, and can be easily scaled up or down. However, depots have limited storage capacity and are not ideal for businesses requiring long-term storage solutions. Warehouses provide more comprehensive storage facilities that are ideal for businesses with complex inventory requirements and long-term storage needs. They are more expensive than depots, require larger infrastructure and a more significant investment in resources.

Another factor to consider when choosing between depots and warehouses is the level of security required for the stored inventory. Warehouses typically have more advanced security measures in place, such as surveillance cameras, security personnel, and access control systems. This makes them a better option for businesses that deal with high-value or sensitive products. Depots, on the other hand, may have limited security measures, making them more vulnerable to theft or damage.

Additionally, businesses must consider the accessibility of the storage facility. Depots are often located in urban areas, making them easily accessible by road or rail. This makes them an ideal option for businesses that require frequent and fast deliveries. Warehouses, on the other hand, may be located in remote areas, making them less accessible. This can result in longer delivery times and higher transportation costs.

Which is More Cost-Effective: Depots or Warehouses?

The cost-effectiveness of using depots versus warehouses ultimately depends on a business's specific needs and requirements. Businesses that require short-term storage facilities and have limited inventory requirements would typically find depots to be the more cost-effective option. On the other hand, businesses that have complex inventory needs and require long-term storage solutions would find warehouses to be more cost-effective.

The Impact of Technology on Depots and Warehouses: A Comparative Analysis

The use of technology in depots and warehouses can increase their efficiency, reduce operational costs, and improve overall productivity. Depots can benefit from real-time tracking solutions, enabling businesses to monitor their inventory levels and shipping activities accurately. Warehouses can benefit from advanced automation solutions, such as conveyor systems and automated storage and retrieval systems, which can increase storage capacity and improve material handling processes.

Choosing the Best Option for Your Business: A Guide to Deciding Between Depots and Warehouses

When deciding between depots and warehouses, businesses must consider their specific needs and requirements. Factors such as inventory requirements, storage duration, delivery distance, and shipping locations must be taken into account. Businesses must also assess their resources and budget to determine which option is the most viable one for their operations. A combination of both depots and warehouses may also be a viable option for businesses with diverse inventory requirements.

Case Studies: Real-Life Examples of Companies that Use Depots or Warehouses

Several companies use depots or warehouses to manage their inventory and supply chain operations. For example, Amazon has a network of warehouses and fulfillment centers across the world to ensure prompt and efficient product delivery. Walmart uses depots to store and manage its inventory to ensure timely delivery of products to its stores.

Planning and Implementing an Effective Depot or Warehouse Strategy

Planning and implementing an effective depot or warehouse strategy is essential to maximize the benefits of these storage facilities. Businesses must develop a solid plan that outlines their inventory requirements, storage needs, and distribution networks. They must also consider the infrastructure requirements, staffing needs, and technology solutions required to achieve their objectives. Regular performance evaluations and adjustments are necessary to ensure that the depot or warehouse strategy is optimized for optimal results.

Future Trends and Innovations in Depots and Warehouses

The future of depots and warehouses is heavily influenced by technological advancements. The use of automation, artificial intelligence, and robotics is expected to increase in the coming years, leading to more efficient and effective storage and inventory management solutions. The adoption of renewable energy solutions, such as solar power and wind energy, is also becoming increasingly popular among companies looking to optimize sustainability and reduce their carbon footprint.

In summary, depots and warehouses are integral components of supply chain and logistics networks that provide storage solutions for businesses with different inventory requirements. Understanding the differences between depots and warehouses can help businesses make informed decisions on which storage solution best suits their needs and make the most of their budget and resources.