DIM Weight Compliance Software vs. CubiScan Dimensioning Systems

For businesses involved in shipping products, shipping costs represent a significant overhead expense. Reducing these costs can be achieved through accurate package dimensioning, where DIM weight compliance software and CubiScan dimensioning systems play pivotal roles. This article delves into the differences and similarities between these two technologies, aiding you in selecting the most suitable option for your business needs.

Understanding the Importance of DIM Weight Compliance

Dimension (DIM) weight compliance is a policy adopted by major shipping carriers to optimize shipping costs. "DIM" stands for dimensional weight, a calculation that considers package dimensions in addition to weight to determine shipping costs. Consequently, larger packages incur higher shipping fees regardless of their actual weight. DIM weight compliance encourages businesses to use appropriately sized packaging, thereby reducing the cost associated with shipping oversized items.

Beyond cost reduction, DIM weight compliance positively impacts the environment. Appropriately sized packaging minimizes wasted space in shipping containers, decreasing the number of shipments required. According to the Environmental Protection Agency, optimizing shipping can significantly reduce fuel consumption and greenhouse gas emissions, making DIM weight compliance both financially and environmentally beneficial.

The Significance of Accurate Package Dimensions

Accurate package dimensions are essential for determining correct shipping costs. Incorrect measurements can result in underestimating or overestimating costs, leading to financial losses through high shipping fees or lost customers. According to a study by Investopedia, precise dimensioning not only reduces shipping expenses but also streamlines the shipping process, enhances customer satisfaction, and mitigates the risk of product damage or loss during transit.

Compliance with shipping regulations is another critical aspect of accurate package dimensioning. Many carriers have specific dimension requirements, and non-compliance can lead to additional fees or package rejection. Ensuring accurate and compliant dimensions prevents these issues, ensuring timely and safe delivery of products.

Furthermore, accurate dimensions contribute to sustainability efforts by optimizing package sizes. This optimization reduces the need for excessive packaging materials and the space required for shipping, resulting in decreased carbon emissions and promoting an eco-friendly shipping process.

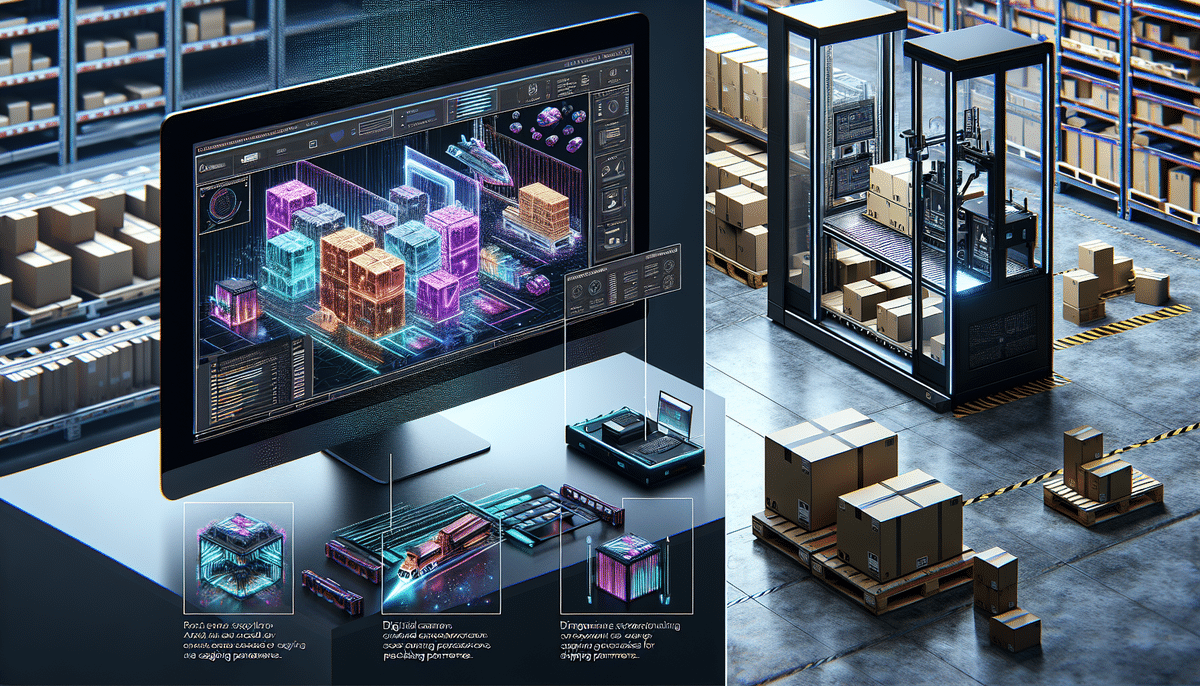

Comparing DIM Weight Compliance Software and CubiScan Dimensioning Systems

DIM Weight Compliance Software

DIM weight compliance software typically employs three-dimensional cameras or scanners to capture and analyze package dimensions. These systems are designed to integrate seamlessly with existing shipping software, automating dimension calculations and shipping cost determinations. This automation significantly reduces manual errors and speeds up the shipping process.

CubiScan Dimensioning Systems

CubiScan dimensioning systems utilize a combination of sensors and advanced dimensioning technology to accurately calculate package dimensions. Known for their high accuracy and precision, CubiScan systems can handle a wide range of package sizes, making them suitable for businesses with diverse shipping needs.

Key Differences

- Accuracy: CubiScan systems offer higher accuracy with a margin of error around 0.25 inches compared to DIM weight compliance software's margin of about one inch.

- Flexibility: DIM weight compliance software accommodates a wider range of package sizes, including smaller packages, whereas CubiScan systems generally require a minimum package size of approximately 6 x 6 x 6 inches.

- Cost: DIM weight compliance software is generally less expensive, while CubiScan systems require a higher initial investment but offer greater durability and longevity.

- Integration: DIM weight compliance software can seamlessly integrate with various shipping and logistics software, facilitating efficient data sharing. CubiScan systems may require additional customization for similar levels of interoperability.

Factors to Consider When Choosing a Dimensioning Solution

Package Size and Weight

Assess the variety and size of packages your business handles. If you frequently ship smaller items, DIM weight compliance software may be more suitable. For larger or irregularly shaped packages, CubiScan systems offer the necessary precision.

Budget Constraints

Consider both the initial investment and ongoing costs. While DIM weight compliance software is more cost-effective upfront, CubiScan systems may offer better long-term value due to their durability and accuracy.

Accuracy and Precision Requirements

Higher accuracy reduces the risk of shipping cost miscalculations. Businesses that prioritize precise shipping cost determinations may benefit more from CubiScan systems.

Durability and Longevity

CubiScan systems are known for their robust construction, making them a reliable long-term investment. In contrast, DIM weight compliance software, which relies on cameras or scanners, may require more frequent maintenance or upgrades.

Integration Capabilities

Ensure the dimensioning solution integrates smoothly with your existing shipping and warehouse management systems to streamline operations and reduce manual input.

Real-World Applications and Case Studies

Many companies leverage DIM weight compliance software and CubiScan dimensioning systems to optimize their shipping processes. For example, a leading e-commerce retailer implemented CubiScan systems, resulting in a 15% reduction in shipping costs and enhanced accuracy in package dimensioning. On the other hand, a small online seller adopted DIM weight compliance software, enabling them to efficiently manage a high volume of small packages and reduce overall shipping expenses by 10%.

These examples illustrate how different businesses can benefit from the tailored advantages of each dimensioning solution based on their specific needs.

Tips for Optimizing Shipping Costs

- Select the Right Dimensioning System: Choose a system that aligns with your business size, package variety, and budget.

- Ensure Precise Measurements: Regularly calibrate your dimensioning equipment to maintain accuracy.

- Pack Efficiently: Utilize space-saving packaging techniques to maximize the use of shipping containers.

- Choose Cost-Effective Carriers: Compare shipping rates and services from different carriers to find the most economical options.

- Automate Shipping Processes: Integrate your dimensioning system with shipping software to reduce manual errors and save time.

Conclusion

Choosing the right dimensioning solution is crucial for reducing shipping costs, enhancing process efficiency, and improving customer satisfaction. Businesses handling smaller packages or operating with budget constraints may find DIM weight compliance software to be the optimal choice. Conversely, those dealing with larger packages or requiring high accuracy and precision may benefit more from CubiScan dimensioning systems. Assessing your specific business needs will guide you in selecting the most effective dimensioning solution, ultimately contributing to your company's profitability and sustainability.