Introduction to IoT Warehouse Automation

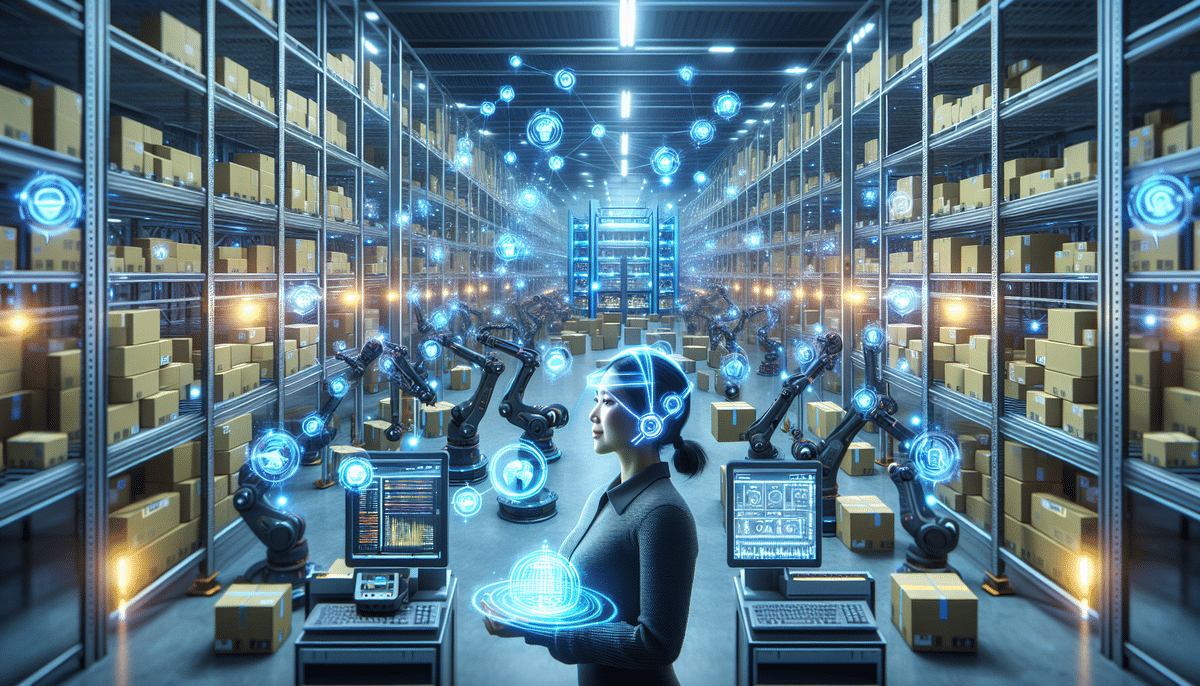

In today’s fast-paced business environment, organizations continually seek innovative ways to enhance their operations, streamline processes, and boost efficiency. IoT warehouse automation emerges as a transformative technology with the potential to revolutionize warehouse operations. This article explores the depths of IoT warehouse automation, providing comprehensive insights and essential information for leveraging this powerful technology.

Benefits of IoT in Warehouse Operations

Real-Time Inventory Tracking

IoT sensors offer precise, up-to-date information on stock levels, locations, and movements. This real-time visibility allows warehouse managers to make informed decisions, minimizing stockouts and overstock situations. According to a Business News Daily report, real-time inventory tracking can lead to a 20% reduction in inventory costs.

Cost Reduction

By automating inventory tracking and management, IoT reduces the reliance on manual processes, thereby cutting labor costs. Furthermore, automation minimizes human errors, leading to lower operational costs and increased accuracy.

Enhanced Safety

IoT improves warehouse safety by continuously monitoring environmental factors and worker movements. Sensors can detect unsafe conditions, such as extreme temperatures or potential equipment malfunctions, and promptly alert staff to prevent accidents.

Operational Optimization

IoT enables the monitoring of goods and equipment movement within the warehouse, helping to identify bottlenecks and inefficiencies. This insight facilitates the optimization of warehouse layout and workflow, resulting in faster processing times and improved productivity.

Predictive Maintenance

IoT sensors monitor the performance of machinery in real-time, enabling the prediction and prevention of equipment failures. According to a Forrester report, predictive maintenance can reduce downtime by up to 70%, significantly cutting repair costs.

Key Components of IoT Warehouse Automation

Sensors

Sensors are fundamental to IoT warehouse automation, tracking various operational aspects such as temperature, humidity, and movement. These sensors collect data that is essential for monitoring and optimizing warehouse conditions.

Devices

Devices like RFID tags, barcode scanners, and wearable technology are used to track inventory and personnel. These devices facilitate accurate and efficient data collection, enabling real-time monitoring of assets and employees.

Gateways

Gateways serve as communication bridges between sensors and devices, ensuring seamless data transmission. They are critical for maintaining real-time connectivity and data flow within the IoT ecosystem.

Cloud Computing

Cloud computing stores and analyzes the data collected by IoT sensors and devices. It provides actionable insights to warehouse managers, allowing for data-driven decision-making and operational improvements.

Machine Learning and Artificial Intelligence

Machine learning algorithms and artificial intelligence enhance IoT systems by enabling them to learn from collected data and make informed predictions. These technologies improve inventory forecasting, equipment maintenance schedules, and overall operational efficiency.

Implementing IoT Warehouse Automation

Assess Your Needs

Begin by evaluating your warehouse operations to identify areas where IoT can be most beneficial. Determine your automation requirements and set clear objectives for implementing IoT solutions.

Select Appropriate Devices

Choose IoT devices, sensors, and gateways that align with your identified needs. Factors to consider include compatibility with existing systems, reliability, and data accuracy. Resources like Software Advice offer guidance on selecting suitable IoT devices.

Installation and Configuration

Proper installation and configuration of IoT devices and sensors are crucial for accurate data collection. Ensure that all devices are correctly calibrated and connected to the network to facilitate seamless data transmission.

System Integration

Integrate the IoT system with your existing warehouse management system (WMS). This integration ensures that data flows smoothly between systems, enhancing overall operational efficiency.

Training

Provide comprehensive training to personnel on how to use and interpret data from the IoT system. Well-trained staff can effectively leverage IoT insights to optimize warehouse operations.

The Role of Data Analytics in IoT Warehouse Automation

Data analytics plays a pivotal role in IoT warehouse automation. The data collected by sensors and devices is analyzed to generate actionable insights, which can improve inventory management, optimize processes, and enhance performance metrics. By leveraging data analytics, warehouse managers can make informed decisions that drive efficiency and reduce costs.

Predictive Maintenance

Analyzing data from IoT sensors allows warehouse managers to identify potential equipment failures before they occur, enabling proactive maintenance. This approach minimizes downtime and extends the lifespan of critical assets.

Safety Improvements

Data analytics can uncover potential safety hazards by analyzing patterns and trends in the data. This enables managers to implement corrective actions, such as workflow adjustments, additional training, or new safety protocols, thereby enhancing overall warehouse safety.

Challenges and Risk Management in IoT Warehouse Automation

While IoT warehouse automation offers numerous benefits, it also presents potential challenges and risks:

- Cybersecurity Threats: IoT devices can be vulnerable to hacking and security breaches. Implementing robust cybersecurity measures is essential to protect sensitive data.

- Implementation Costs: The initial investment and ongoing maintenance costs of IoT systems can be significant, especially for small and medium-sized businesses.

- System Failures: Malfunctions in critical components can disrupt warehouse operations, leading to delays in order fulfillment and shipping.

- Employee Training: Employees may require training to effectively use and interpret IoT systems, which can present a learning curve during the transition period.

To mitigate these risks, businesses should prioritize cybersecurity, ensure regular maintenance and updates of systems, and provide adequate training for employees. Addressing these challenges can help maximize the benefits of IoT warehouse automation while minimizing potential drawbacks.

Real-World Examples and Case Studies

Many companies have successfully implemented IoT warehouse automation systems, resulting in improved efficiency and reduced costs:

- Amazon: Utilizes IoT sensors to monitor and track inventory in its warehouses, significantly reducing the time and labor required for manual inventory checks.

- UPS: Employs IoT devices to optimize delivery routes, enhancing efficiency and reducing operational costs.

Future Trends in IoT Warehouse Automation

The field of IoT warehouse automation is rapidly evolving, with several emerging trends and advancements:

- Artificial Intelligence and Machine Learning: These technologies will further enhance data analysis, providing more accurate and actionable insights.

- Blockchain Technology: Improving supply chain visibility and transparency, blockchain can enhance trust and security in warehouse operations.

- Edge Computing: Processing data closer to where it is generated will reduce latency and improve real-time decision-making.

- Robotic Process Automation (RPA): Integrating robots with IoT systems will enable more complex and autonomous warehouse operations.

Comparison of Traditional vs. IoT-Powered Warehouse Automation

Traditional warehouse automation relies heavily on manual processes, which can be time-consuming and prone to errors. In contrast, IoT-powered systems automate these processes, offering real-time data and greater accuracy:

- Data Accuracy: IoT systems provide more precise and detailed information compared to manual tracking.

- Cost: While IoT systems require a significant upfront investment, the long-term savings from increased efficiency and reduced errors can offset initial expenses.

- Scalability: IoT-powered systems are more scalable, adapting to businesses of various sizes, whereas traditional systems may struggle to scale efficiently.

Selecting the Right IoT Devices and Sensors for Your Warehouse

When choosing IoT devices and sensors for your warehouse, consider the following factors:

- Automation Needs: Identify the specific automation requirements of your warehouse operations.

- Compatibility: Ensure devices and sensors are compatible with your existing technology and warehouse management system (WMS).

- Reliability and Accuracy: Select devices known for their reliability and precision in data collection.

- Vendor Support: Consider the level of support and service provided by the vendor to ensure smooth implementation and maintenance.

- Scalability: Choose devices and sensors that can scale with your business growth and evolving needs.

Best Practices for Maintaining and Optimizing Your IoT Warehouse Automation System

To ensure the longevity and effectiveness of your IoT warehouse automation system, follow these best practices:

- Regular Calibration and Updates: Regularly calibrate and update all devices and sensors to maintain accuracy and functionality.

- System Monitoring: Continuously monitor the system for anomalies or malfunctions, addressing any issues promptly to prevent disruptions.

- Data Analysis: Regularly analyze the data collected by the system to identify areas for improvement and optimization.

- Employee Training: Provide ongoing training to employees to ensure they are proficient in using and interpreting the IoT system.

- Security Measures: Implement robust cybersecurity protocols to protect the system from potential threats.

Case Study: Enhancing Efficiency and Profitability with IoT Warehouse Automation

Company XYZ, a leading manufacturer, implemented an IoT-enabled warehouse automation system to enhance inventory management and reduce costs. By utilizing IoT sensors to track inventory movement and data analytics to analyze collected data, they optimized their warehouse processes, resulting in reduced labor costs and improved efficiency. Consequently, Company XYZ experienced a significant increase in profitability and a substantial reduction in operational costs.

Addressing Common Misconceptions About IoT-Powered Warehouse Automation

Several misconceptions surround IoT-powered warehouse automation:

- Job Loss: While some manual tasks may be automated, IoT systems can create new roles, such as data analysts and system administrators.

- Suitability for All Business Sizes: IoT-powered automation can be scaled to suit businesses of all sizes, offering significant benefits even for smaller operations.

- Complexity: Modern IoT systems are increasingly user-friendly, making them accessible to businesses without extensive technical expertise.

In conclusion, IoT warehouse automation is a rapidly advancing technology with the potential to revolutionize warehouse operations. By implementing an IoT system, businesses can achieve real-time inventory tracking, process optimization, cost reduction, and increased efficiency. Despite potential challenges, the benefits of IoT warehouse automation can provide a competitive advantage to businesses adopting this technology.