Exploring 3PL Warehouse Automation Solutions: What You Need to Know

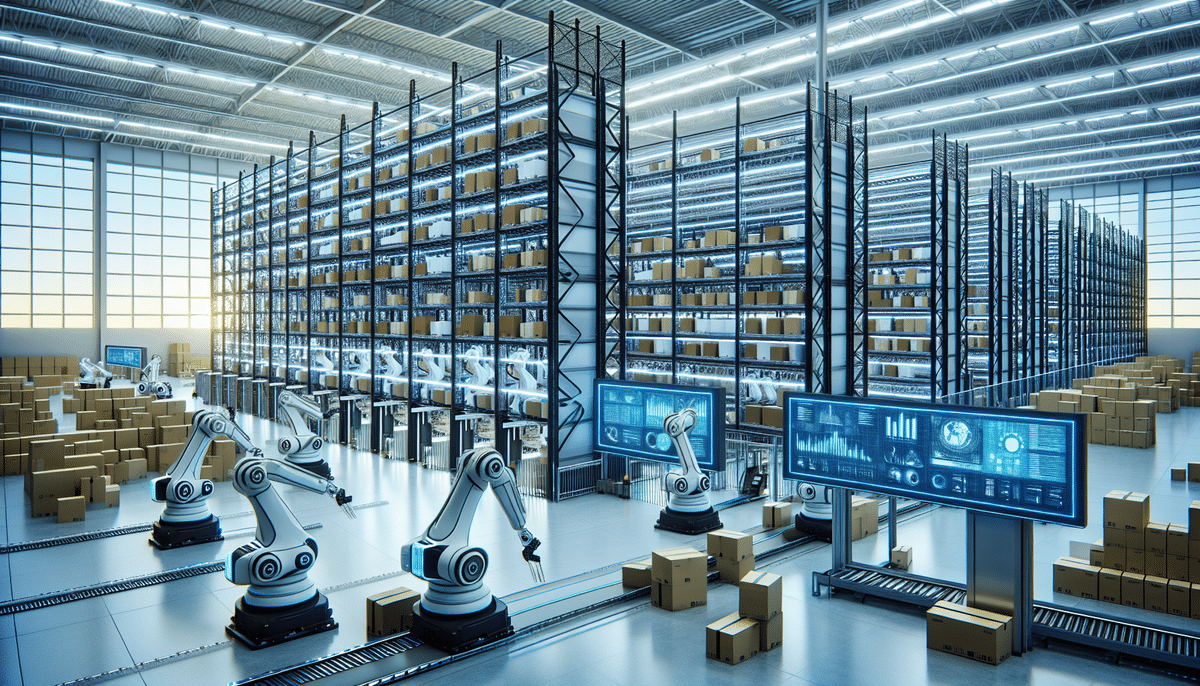

The logistics and warehouse management landscape has undergone a significant transformation in recent years, with businesses increasingly turning to automation to enhance operations and boost efficiency. Third-party logistics (3PL) providers are at the forefront of integrating automation solutions within their warehouses, aiming to deliver faster and more accurate services to their clients. This article delves into the fundamentals of 3PL warehouse automation, its benefits, key considerations for selecting the right solution, challenges during implementation, and future trends shaping the industry.

Understanding the Basics of 3PL Warehouse Automation

Before exploring the advantages of 3PL warehouse automation, it is essential to grasp the foundational concepts of this technology. 3PL warehouse automation involves the integration of advanced technologies such as conveyors, sorters, Automated Storage and Retrieval Systems (ASRS), and robotics to streamline and optimize warehouse operations. By minimizing manual intervention, automation enhances accuracy, efficiency, speed, and overall customer satisfaction.

According to a McKinsey report, warehouses implementing automation solutions have seen a 30% increase in operational efficiency and a significant reduction in error rates.

One of the primary advantages of 3PL warehouse automation is the capacity to manage a high volume of orders with minimal human input. This capability is especially valuable during peak seasons when demand surges, enabling businesses to process, pick, pack, and ship orders swiftly without additional staffing.

Additionally, automation facilitates real-time inventory tracking. Automated systems provide accurate, up-to-date information on inventory levels, assisting businesses in making informed decisions about restocking and replenishment. This reduces the risks of stockouts and overstocking, which can be financially detrimental.

Benefits of Implementing 3PL Warehouse Automation Solutions

Adopting 3PL warehouse automation solutions offers numerous benefits:

- Cost Reduction: Automation decreases labor costs by reducing the need for manual tasks and enhances worker safety.

- Increased Speed and Accuracy: Automated systems speed up order processing and fulfillment while maintaining high levels of accuracy, leading to improved customer satisfaction.

- Space Optimization: Automation optimizes warehouse space utilization, enabling businesses to store more inventory without expanding their physical footprint.

- Real-Time Visibility: Enhanced visibility into inventory levels allows for effective stock management and informed decision-making.

- Error Minimization: Automated handling reduces the likelihood of product damage and order inaccuracies, maintaining product quality and reducing returns.

- Sustainability: Automated systems optimize energy usage and minimize waste, contributing to a lower carbon footprint and supporting sustainable business practices.

Furthermore, a study by Supply Chain Digital highlights that businesses using warehouse automation have reported a 20% reduction in order processing times and a 15% decrease in operational costs.

Selecting the Right 3PL Warehouse Automation Solution for Your Business

Selecting the appropriate 3PL warehouse automation solution can be challenging. Here are key steps and factors to consider:

- Identify Operational Needs: Assess the areas of your warehouse operations that require improvement, such as order processing, inventory management, or picking and packing.

- Research Available Solutions: Explore various automation solutions that align with your identified needs and business objectives.

- Evaluate Key Factors: Consider the cost, scalability, reliability, and compatibility of the solutions with your existing warehouse management systems.

- Customization: Ensure the solution offers customization to fit your unique business processes, including tailored workflows and specialized reporting capabilities.

- Support and Training: Choose a provider that offers comprehensive support and training to facilitate a smooth implementation and maximize the benefits of the automation tools.

For more insights on selecting the right 3PL partner, refer to industry resources such as the Logistics Management guide on choosing a 3PL.

Implementation Considerations and Challenges

Key Considerations

Successful implementation of 3PL warehouse automation requires meticulous planning and consideration of several factors:

- Comprehensive Evaluation: Conduct a thorough assessment of current warehouse operations to pinpoint areas that would benefit most from automation.

- Workforce Impact: Evaluate how automation will affect your workforce and develop a change management strategy to address potential workforce displacement.

- Training: Provide adequate training to employees to ensure they are proficient in using the new automation technologies.

- Technology Selection: Choose technologies that not only fit your current needs but are also scalable to accommodate future growth.

- Partnership with Reputable Providers: Collaborate with established automation providers who can offer ongoing support and maintenance.

Implementing automation without addressing these considerations can lead to disruptions and inefficiencies, undermining the potential benefits.

Common Challenges

While automation offers substantial benefits, its implementation is not without challenges:

- System Integration: Integrating new automation technologies with existing systems can be complex and may require significant adjustments.

- Compatibility Issues: Ensuring compatibility between different pieces of equipment and software is crucial for seamless operations.

- Staff Resistance: Employees may resist changes due to fear of job displacement or apprehension about adopting new technologies.

- High Initial Costs: The upfront investment for automation technologies can be substantial, posing financial challenges for some businesses.

Overcoming these challenges involves strategic planning, effective communication, comprehensive training, and potentially exploring financing options such as leasing or phased implementation.

Case Studies of Successful 3PL Warehouse Automation

Several businesses have leveraged 3PL warehouse automation to enhance their operations:

- DHL Supply Chain: One of the world's largest logistics companies, DHL implemented ASRS and conveyor systems in their warehouses, resulting in a 50% increase in productivity, reduced manual intervention, and improved order accuracy. [Source]

- Amazon: Amazon has pioneered the use of robotics, conveyor belts, and automated storage and retrieval systems across its warehouses. These technologies have enabled Amazon to process orders more rapidly, reduce delivery times, decrease labor costs, and enhance warehouse safety. [Source]

Future Trends in 3PL Warehouse Automation

The future of 3PL warehouse automation is poised for significant advancements as technology continues to evolve:

- Artificial Intelligence (AI) and Machine Learning: AI-driven systems will enhance decision-making, predictive maintenance, and demand forecasting, leading to more efficient operations.

- Advanced Robotics: Next-generation robots will offer greater adaptability, handling a wider range of tasks with increased precision and speed.

- Drones: Drones are expected to play a role in inventory management and the delivery of goods, reducing reliance on manual processes.

- Internet of Things (IoT): IoT devices will provide deeper insights into inventory movements, environmental conditions, and equipment performance, facilitating data-driven decisions.

- Autonomous Vehicles: Autonomous forklifts and vehicles will streamline internal transportation within warehouses, enhancing safety and efficiency.

These trends suggest a move towards more interconnected, intelligent, and autonomous warehouse environments, further transforming the logistics industry.

The Role of Robotics and AI in 3PL Warehouse Automation

Robotics and AI are central to the evolution of 3PL warehouse automation:

- Robotics: Robots perform complex tasks such as picking, packing, and sorting with high precision and speed. They can operate continuously, reducing downtime and increasing throughput.

- Artificial Intelligence: AI algorithms optimize warehouse operations by improving inventory management, demand forecasting, and maintenance scheduling. AI also enables adaptive systems that can respond to real-time changes in the warehouse environment.

According to TechRadar, the integration of AI and robotics in warehouses is expected to increase operational efficiency by up to 40% over the next five years.

Cost Analysis: Evaluating the ROI of 3PL Warehouse Automation Solutions

Investing in 3PL warehouse automation necessitates a thorough evaluation of the return on investment (ROI). Factors influencing ROI include:

- Initial Investment: The upfront costs of purchasing and installing automation equipment.

- Operational Savings: Reductions in labor costs, error rates, and waste.

- Increased Productivity: Higher order processing rates and improved throughput.

- Long-Term Benefits: Enhanced scalability, flexibility, and the potential for future growth.

Businesses should conduct a cost-benefit analysis to assess whether the long-term savings and efficiency gains outweigh the initial expenses. Additionally, exploring financing options like leasing or incremental implementation can make automation more financially manageable.

A report by Forbes suggests that companies implementing warehouse automation can achieve an ROI within 24 to 36 months, depending on the scale of automation and specific operational improvements.

Implementing a Successful Change Management Strategy for 3PL Warehouse Automation

Effective change management is critical for the successful implementation of 3PL warehouse automation:

- Stakeholder Involvement: Engage all stakeholders, including employees, management, and partners, early in the process to garner support and address concerns.

- Communication: Maintain open lines of communication to keep everyone informed about the goals, benefits, and progress of the automation initiative.

- Training Programs: Develop comprehensive training programs to equip employees with the necessary skills to operate and manage new automation technologies.

- Employee Participation: Involve employees in the implementation process to foster a sense of ownership and reduce resistance to change.

According to Harvard Business Review, effective change management can increase the likelihood of successful technology implementation by up to 70%.

Tips for Ensuring Maximum Efficiency and Productivity with 3PL Warehouse Automation Solutions

To maximize the benefits of 3PL warehouse automation, businesses should focus on continuous improvement:

- Regular Assessment: Continuously evaluate warehouse operations to identify new areas for improvement and optimization.

- Maintenance: Implement a proactive maintenance schedule to ensure automation systems remain operational and prevent downtime.

- Benchmarking: Compare your warehouse performance against industry best practices to identify gaps and opportunities for enhancement.

- Adopt Best Practices: Stay informed about the latest trends and technologies in warehouse automation to keep your operations competitive.

Embracing a culture of continuous improvement ensures that automation solutions are effectively utilized and adapted to evolving business needs.

Understanding the Impact of COVID-19 on the Adoption of 3PL Warehouse Automation Solutions

The COVID-19 pandemic significantly accelerated the adoption of 3PL warehouse automation solutions:

- Increased Demand for E-commerce: The surge in online shopping during the pandemic heightened the need for efficient and scalable warehouse operations.

- Social Distancing Measures: To comply with health guidelines, businesses sought automation to reduce the reliance on manual labor and maintain operations with a limited workforce.

- Enhanced Supply Chain Visibility: The pandemic underscored the importance of real-time inventory tracking and agile supply chain management, both of which are facilitated by automation.

According to a Bain & Company analysis, the pandemic led to a 40% increase in the adoption of warehouse automation technologies as businesses sought to build more resilient and adaptable supply chains.

Top Providers of 3PL Warehouse Automation Solutions: A Comparison and Review

Several providers offer robust 3PL warehouse automation solutions. Evaluating these providers based on key criteria is essential for selecting the best fit for your business:

- Swisslog: Known for its comprehensive automation solutions including conveyors, automated storage systems, and robotics. Swisslog emphasizes scalability and integration with existing systems. [Website]

- Dematic: Offers a wide range of warehouse automation technologies such as ASRS, conveyor systems, and AI-driven software. Dematic focuses on end-to-end supply chain solutions and innovation. [Website]

- KNAPP: Specializes in intelligent automation solutions including warehouse control systems, picking technologies, and robotics. KNAPP is known for its innovation in dynamic storage systems. [Website]

When selecting a provider, consider factors such as:

- Cost: Assess the overall investment required and the potential ROI.

- Reliability: Choose providers with a proven track record of successful implementations.

- Scalability: Ensure the solutions can scale with your business growth.

- Compatibility: Verify that the automation solutions integrate seamlessly with your existing warehouse management systems.

For more comparisons and reviews of 3PL automation providers, refer to industry analysis on platforms like Logistics Management.

In conclusion, adopting 3PL warehouse automation solutions offers businesses substantial benefits, including enhanced efficiency, accuracy, and customer satisfaction. However, successful implementation requires careful planning, consideration of costs and change management, and selecting the right automation partner. Businesses that effectively integrate automation and continuously optimize their warehouse operations are well-positioned to achieve maximum efficiency and productivity.