Understanding the Challenges and Impacts of Inventory Shortages During Peak Seasons

During peak seasons, businesses can face a variety of challenges related to inventory shortages. These shortages can occur for several reasons, such as an unexpected surge in demand, delayed deliveries, or production issues. Whatever the cause, inventory shortages can significantly impact a business's performance, leading to lost profits and dissatisfied customers. Fortunately, there are alternative delivery methods that businesses can implement to overcome these shortages and ensure timely product delivery.

Understanding the Challenges of Inventory Shortages During Peak Seasons

Inventory shortages during peak seasons can be particularly challenging for businesses, as they often occur during periods of high demand. This can result in long wait times for customers, potential loss of future business, and even reputational damage. Additionally, inventory shortages raise concerns about a business's ability to manage its supply chain, potentially leading to a loss of trust from stakeholders and investors.

One of the main causes of inventory shortages during peak seasons is the lack of accurate forecasting. Businesses may underestimate the demand for their products, leading to insufficient inventory levels. On the other hand, overestimating demand can result in excess inventory, which can be costly to store and manage. To address this challenge, businesses can:

- Utilize data analytics and market research to better understand customer behavior and predict demand.

- Implement effective inventory management systems.

- Collaborate closely with suppliers to maintain optimal inventory levels during peak seasons.

According to a Forbes article, businesses that leverage advanced data analytics can improve their demand forecasting accuracy by up to 30%, significantly reducing the risk of inventory shortages.

Impact of Inventory Shortages on Businesses

The Impact of Inventory Shortages on Your Business: A Comprehensive Overview

The impact of inventory shortages on your business can be significant. It can result in decreased sales and affect the business's ability to meet demand and fulfill orders. The overall result can be a loss of revenue for the business as well as a loss of potential future business. Inventory shortages can also lead to increased costs as the business may have to seek alternative delivery methods to meet consumer demand.

Moreover, inventory shortages can affect the reputation of the business. Customers may become frustrated with the unavailability of products and may turn to competitors, resulting in a loss of market share. This can also lead to negative reviews and word-of-mouth publicity, which can further damage the business's reputation.

On the other hand, effective inventory management can help businesses avoid inventory shortages. By implementing inventory tracking systems and forecasting demand, businesses can ensure that they have the right amount of inventory to meet customer demand. This can lead to increased customer satisfaction, repeat business, and ultimately, increased revenue for the business.

Alternative Delivery Methods to Overcome Inventory Shortages

Exploring the Role of Delivery Methods in Minimizing Inventory Shortages

Delivery methods play a critical role in minimizing inventory shortages during peak seasons. Methods such as drop-shipping, cross-docking, and third-party fulfillment centers can help businesses ensure timely delivery despite inventory shortages. These methods allow businesses to promptly restock depleted items and meet customer demand in a timely fashion, thus avoiding loss of revenue and customer trust.

Drop-shipping is a popular delivery method that allows businesses to ship products directly from the manufacturer or supplier to the customer. This method eliminates the need for businesses to hold inventory, reducing the risk of inventory shortages.

Cross-docking involves transferring products from one truck to another without storing them in a warehouse. This method is ideal for businesses that need to quickly move products from one location to another.

Third-party fulfillment centers store and manage inventory on behalf of businesses and handle the entire fulfillment process, from receiving orders to shipping products to customers. This method allows businesses to focus on other aspects of their operations while ensuring timely delivery and minimizing the risk of inventory shortages.

For more information on shipping carriers, visit the top shipping carriers for your business page.

The Pros and Cons of Different Delivery Methods for Your Business During Peak Seasons

There are pros and cons to using different delivery methods for overcoming inventory shortages during peak seasons. For example:

- Drop-shipping can help reduce costs and lead times but may result in lower quality control.

- Cross-docking can help reduce inventory holding costs but may result in longer delivery times.

- Third-party logistics providers (3PL) can help manage inventory and shipping needs more efficiently but may result in higher costs and less control over the shipping process.

Businesses must carefully weigh these pros and cons when selecting the best delivery method.

Using a third-party logistics provider (3PL) can help businesses manage their inventory and shipping needs more efficiently, as 3PLs have the expertise and resources to handle complex logistics operations. However, using a 3PL can also result in higher costs and less control over the shipping process.

In addition, businesses can explore the option of using a combination of delivery methods to optimize their operations during peak seasons. For example, they can use drop-shipping for certain products and cross-docking for others, depending on their inventory levels and customer demand. This approach can help businesses strike a balance between cost-effectiveness and quality control while ensuring timely delivery to their customers.

Leveraging Technology to Combat Inventory Shortages

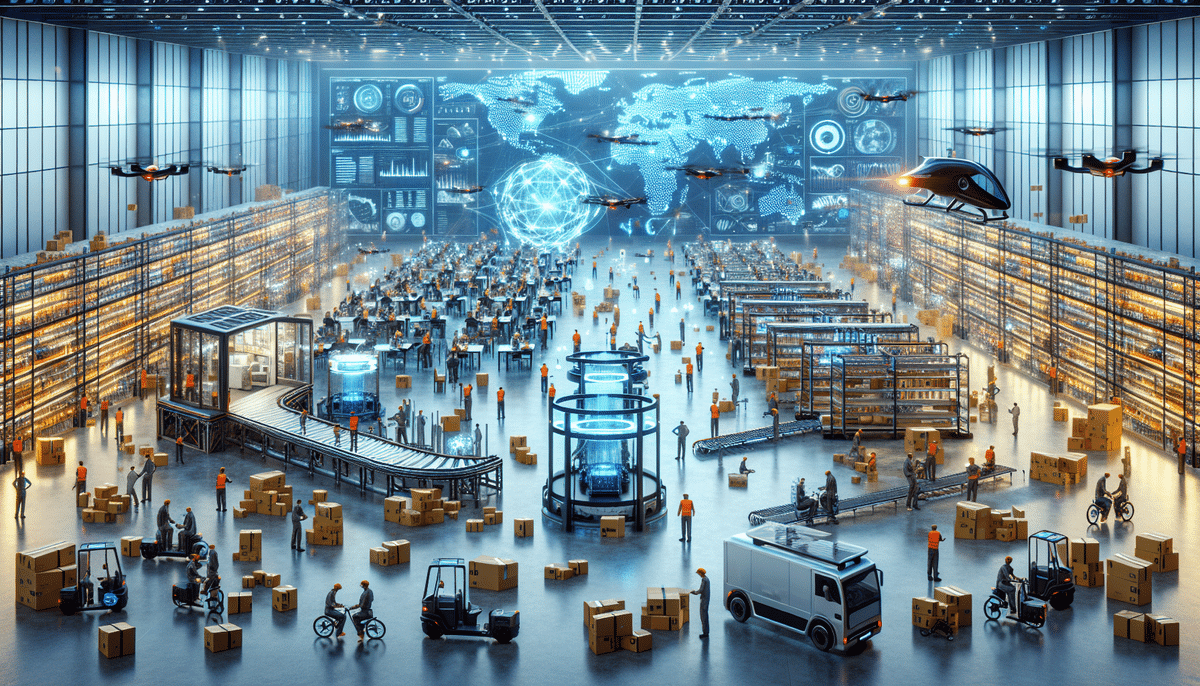

How Technology is Revolutionizing the Delivery Industry to Tackle Inventory Shortages

The use of technology is revolutionizing the delivery industry and providing businesses with alternative delivery methods to overcome inventory shortages. Technologies such as radio-frequency identification (RFID) and global positioning systems (GPS) can help optimize deliveries, reducing wait times and increasing overall efficiency.

Additionally, the use of predictive analytics can help businesses better forecast demand, thus reducing the chances of inventory shortages occurring in the first place. According to a McKinsey report, businesses adopting predictive analytics have seen a 20% improvement in their inventory management accuracy.

Another way technology is revolutionizing the delivery industry is through the use of drones. Drones can deliver packages quickly and efficiently, especially in hard-to-reach areas. This technology is particularly useful for delivering medical supplies to remote areas or during natural disasters when traditional delivery methods may not be possible.

Furthermore, the use of artificial intelligence (AI) is transforming the delivery industry. AI-powered systems can optimize delivery routes, predict traffic patterns, and even monitor weather conditions to ensure timely and safe deliveries. This technology can also help reduce delivery costs and improve customer satisfaction by providing real-time updates on delivery status and estimated delivery times.

Leveraging Big Data to Manage Supply Chain Risks and Deliveries During Peak Seasons

Big data can be leveraged to manage supply chain risks and deliveries during peak seasons. Businesses can use advanced predictive analytics tools to forecast consumer demand and reduce the likelihood of inventory shortages. Additionally, businesses can analyze vast amounts of data to identify patterns and trends that may indicate future inventory shortages, allowing them to take preventive measures ahead of time.

For example, by analyzing purchasing trends, seasonal demand fluctuations, and external factors like economic indicators, businesses can make more informed decisions about inventory levels and delivery schedules.

Diversifying Delivery Options

Diversifying Your Delivery Options: A Key Strategy for Overcoming Inventory Shortages

A key strategy for overcoming inventory shortages is diversifying delivery options. Rather than relying on a single delivery method, businesses can use multiple methods to ensure timely deliveries despite inventory shortages. This can be accomplished by:

- Leveraging multiple shipping carriers.

- Utilizing regional distribution centers.

- Partnering with third-party fulfillment centers.

Another way to diversify delivery options is by offering alternative delivery methods such as curbside pickup or local delivery. This can be especially useful for businesses with a physical storefront or those located in densely populated areas. By offering these options, businesses can provide customers with a convenient and flexible way to receive their orders while also reducing the strain on traditional shipping methods.

In addition to diversifying delivery options, businesses can also consider implementing inventory management software to help optimize their inventory levels. This can help prevent inventory shortages from occurring in the first place by providing real-time data on inventory levels and demand. By having a better understanding of their inventory, businesses can make more informed decisions about when and how to restock, reducing the likelihood of inventory shortages and the need to rely on multiple delivery methods.

Innovative and Collaborative Approaches to Inventory Management

Innovative Approaches to Overcoming Inventory Shortages During Peak Seasons

Overcoming inventory shortages during peak seasons requires innovative approaches that go beyond traditional delivery methods. One innovative approach is to invest in 3D printing technology, which can allow businesses to rapidly produce products on demand, thus reducing wait times and costly inventory surpluses.

Additionally, businesses can leverage crowdsourced delivery networks to meet demand during peak seasons. This approach can increase delivery capacity quickly without the need for significant capital investment.

Another innovative approach to overcoming inventory shortages during peak seasons is to implement a just-in-time (JIT) inventory system. This system involves ordering and receiving inventory only when it is needed, rather than keeping a large stockpile of products on hand. This can help businesses save money on storage costs and reduce the risk of overstocking or understocking.

Furthermore, businesses can consider partnering with other companies to share inventory during peak seasons. This can be especially beneficial for businesses that have complementary products or services. By sharing inventory, businesses can meet demand without having to invest in additional inventory or production capacity.

Collaborative Approaches to Overcoming Supply Chain Disruptions and Deliveries During Peak Seasons

Collaborative approaches to overcoming supply chain disruptions and deliveries during peak seasons can lead to better outcomes for businesses. These approaches can include:

- Partnering with alternative suppliers to diversify the supply base.

- Using crowdsourced delivery networks to increase delivery capacity.

- Collaborating with other businesses to share resources and streamline operations.

By working together, businesses can overcome inventory shortages and ensure timely delivery despite disruptive events. Collaborative platforms and industry alliances can facilitate such partnerships, enabling businesses to share information and resources more effectively.

In conclusion, overcoming inventory shortages during peak seasons requires adaptable delivery methods and effective supply chain management practices. By diversifying delivery options, leveraging technological advances, and collaborating with partners and stakeholders, businesses can efficiently and effectively meet consumer demand even during the most challenging times.

Navigating Supply Chain Challenges to Ensure Timely Delivery

Navigating Supply Chain Challenges to Ensure Timely Delivery Despite Inventory Shortages

Navigating supply chain challenges is critical for ensuring timely delivery despite inventory shortages. This can include:

- Using a multi-tiered approach to supply chain management.

- Leveraging supplier collaboration to enhance supply chain resilience.

- Improving purchasing practices to ensure timely procurement of materials.

Additionally, businesses can use logistics optimization software to identify areas for improvement in their supply chain, providing better visibility and efficiency. Tools like supply chain optimization software can offer real-time insights and analytics to streamline operations.

Optimizing Delivery Processes

How to Optimize Your Delivery Processes to Combat Inventory Shortages

Optimizing delivery processes is essential when combating inventory shortages. This can be accomplished by:

- Implementing real-time tracking systems that provide visibility into every stage of the delivery process.

- Improving the accuracy of demand forecasting models using advanced analytics.

- Establishing backup delivery options for use in the event of a disruption in the supply chain.

According to a study by Harvard Business Review, businesses that optimize their delivery processes can reduce delivery times by up to 25% and increase customer satisfaction ratings by 15%.

The Future of Delivery Services in Overcoming Inventory Shortages

The Future of Delivery Services in Overcoming Inventory Shortages During Peak Seasons

The future of delivery services looks promising in terms of overcoming inventory shortages during peak seasons. Advancements in technology such as drone delivery, robotics, and autonomous vehicles will become increasingly prevalent, allowing for faster and more efficient delivery options. Additionally, businesses may explore the use of decentralized delivery networks to move goods to consumers more quickly and effectively.

Emerging technologies like blockchain are also expected to play a role in enhancing supply chain transparency and security, further mitigating the risks of inventory shortages.

Best Practices for Managing Inventory and Deliveries

Best Practices for Managing Your Inventory and Deliveries During Peak Seasons

Managing inventory and deliveries during peak seasons requires careful planning, communication, and execution. Best practices include:

- Using data analytics to forecast inventory demand and optimize inventory management practices.

- Ensuring efficient communication between all parties involved in the supply chain, including suppliers and customers, to reduce lead times and increase delivery efficiency.

- Implementing scalable logistics solutions that can adapt to fluctuating demand levels.

By adopting these best practices, businesses can better navigate the complexities of peak season demands and maintain high levels of customer satisfaction.

Conclusion

In conclusion, overcoming inventory shortages during peak seasons requires adaptable delivery methods and effective supply chain management practices. By diversifying delivery options, leveraging technological advances, and collaborating with partners and stakeholders, businesses can efficiently and effectively meet consumer demand even during the most challenging times.