Exploring the 8 Types of Warehouses in Supply Chain Management

Effective supply chain management hinges on the strategic use of warehouses. These facilities serve as centralized hubs for inventory storage, order processing, and distribution, playing a pivotal role in optimizing logistics operations. This article delves into the eight primary types of warehouses used in supply chain management, highlighting their unique functions and benefits to help businesses enhance their logistics strategies.

Why Warehouse Management is Critical for Supply Chain Success

Warehouse management is a cornerstone of successful supply chain operations. It encompasses the oversight of inventory levels, order fulfillment, and transportation logistics, ensuring smooth and efficient processes. Poor warehouse management can result in inventory shortages, delayed shipments, and operational inefficiencies, directly impacting a company's profitability and customer satisfaction.

Effective warehouse management not only ensures timely delivery of products but also reduces operational costs and boosts profitability. According to a Statista 2023 report, optimized warehouse operations can decrease costs by up to 20%. Efficient inventory management prevents overstocking or stockouts, reducing unnecessary expenses and lost sales opportunities. Additionally, streamlined warehouse operations optimize transportation routes, cutting transportation costs and enhancing customer satisfaction in a competitive market.

The Strategic Role of Warehouses in the Supply Chain

Warehouses are integral to both inbound and outbound logistics within the supply chain. They manage inventory levels to ensure products are readily available for shipment, provide centralized locations for order processing, and facilitate real-time tracking of shipments. According to the Forbes Technology Council, modern warehouses function as distribution centers, handling products destined for multiple locations and enhancing overall supply chain fluidity.

Moreover, warehouses contribute to significant cost savings and improved delivery times by consolidating shipments from various suppliers. This consolidation reduces the number of transportation vehicles needed, saving costs and lowering carbon emissions. Strategically located warehouses closer to customer bases can drastically reduce delivery times, improving customer satisfaction and loyalty.

Understanding the Different Types of Warehouses

In supply chain management, warehouses can be categorized into eight main types, each serving distinct purposes:

1. Public Warehouses

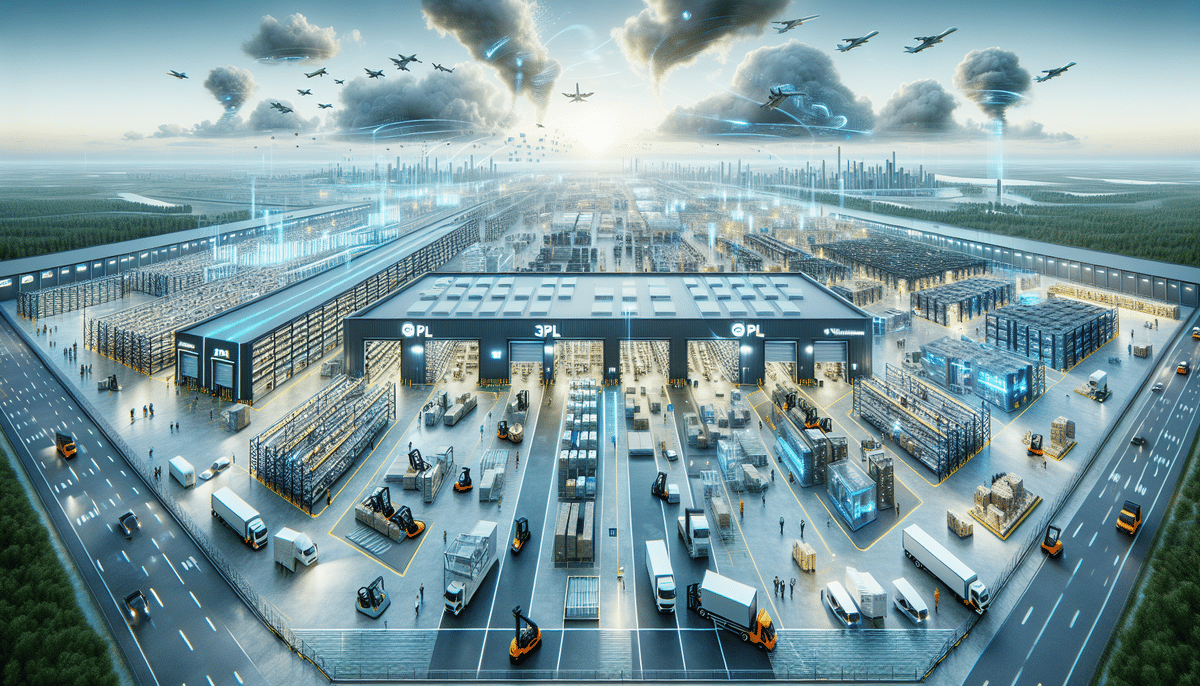

Public warehouses are managed by third-party logistics (3PL) providers, offering storage, inventory management, and order fulfillment services on a contract basis. Major 3PL providers like UPS and FedEx operate these facilities, making them ideal for small to medium-sized businesses that require flexible storage and distribution without the overhead of managing their own facilities.

According to a Logistics Management 2023 report, the public warehousing sector has experienced a 15% growth over the past year, driven by the increasing demand for adaptable logistics solutions.

2. Private Warehouses

Owned and operated by the businesses themselves, private warehouses cater to companies needing extensive storage for large volumes of products over extended periods. These warehouses offer greater control over supply chain processes, including security measures, inventory management, and operational protocols, allowing businesses to tailor operations to their specific needs.

3. Distribution Centers

Distribution centers are expansive warehouses that serve as the logistical backbone of the supply chain. They handle centralized inventory storage, order processing, and shipping for businesses managing large volumes of products across multiple locations. Typically operated by major retailers or manufacturers, distribution centers manage both inbound and outbound logistics to ensure efficient product flow.

Data from Supply Chain Dive 2023 reveals that distribution centers account for roughly 30% of total logistics costs among major retailers, underscoring their critical role in supply chain efficiency.

4. Contract Warehouses

Contract warehouses represent a hybrid between public and private warehouses. Typically owned and operated by 3PL providers, these facilities are dedicated to one or a few businesses under long-term contracts. This arrangement provides the benefits of private warehouses, such as dedicated space and customized services, without the substantial capital investment required for ownership and operation.

5. Automated Warehouses

Automated warehouses leverage advanced robotics and automation technologies to enhance order fulfillment and processing efficiency. These facilities are ideal for businesses that demand high-speed, high-volume operations with minimal manual intervention. Automation increases accuracy, reduces errors, and lowers operational costs. According to a Robotics Business Review 2023, automated warehouses can achieve order accuracy rates of up to 99% and cut fulfillment times by 50%.

6. Cross-Docking Facilities

Designed to minimize inventory storage duration, cross-docking facilities facilitate the rapid movement of products from inbound to outbound transportation without long-term storage. These facilities handle the receipt of incoming shipments, sort products by destination, and immediately load them onto outbound vehicles. Cross-docking reduces handling costs and accelerates delivery times.

7. Climate-Controlled Warehouses

Climate-controlled warehouses maintain specific temperature and humidity levels, making them essential for storing perishable goods such as food, pharmaceuticals, and certain chemicals. Equipped with specialized cooling, heating, and humidity control systems, these warehouses ensure product quality and extend shelf life by providing optimal storage conditions.

8. Multi-Client Warehouses

Multi-client warehouses are shared facilities utilized by multiple businesses for product storage. Managed by 3PL providers, these warehouses offer shared resources like labor, equipment, and space, which can lead to reduced costs and enhanced efficiency. This setup provides businesses with flexible storage and distribution options, allowing them to scale operations as needed without significant investments in infrastructure.

Just-in-Time Inventory Management and Its Impact on Warehousing

Just-in-time (JIT) inventory management is a strategy aimed at reducing inventory holding costs and maximizing efficiency by ensuring products are delivered to warehouses only when needed for order fulfillment. This approach relies on precise inventory tracking and coordinated transportation logistics to maintain minimal inventory levels without compromising on product availability.

One of the primary advantages of JIT is the significant reduction in inventory storage requirements, leading to cost savings by eliminating the need for excess inventory storage and maintenance. Additionally, JIT minimizes the risk of inventory obsolescence by ensuring that only necessary products are ordered and stored, thereby reducing waste.

However, implementing JIT requires seamless coordination among suppliers, transportation providers, and warehouse staff. Any disruptions in the supply chain, such as delays in shipments or production halts, can result in stockouts and delays in order fulfillment, adversely affecting customer satisfaction. According to a McKinsey & Company 2023 report, businesses adopting JIT strategies have achieved operational efficiencies improvements of up to 25%, though they must invest in robust supply chain coordination to mitigate potential risks.

How to Optimize Warehouse Layout and Design for Efficient Operations

An optimized warehouse layout and design are essential for enhancing operational efficiency. Key considerations include the types of products stored, order volumes, and transportation logistics. Effective layout design maximizes storage space utilization, reduces movement time, and minimizes the likelihood of errors during order fulfillment.

Integrating technology is crucial for warehouse optimization. Implementing Warehouse Management Systems (WMS) and automated material handling equipment can substantially improve operational efficiency and accuracy. WMS facilitates real-time inventory tracking, streamlined order processing, and effective labor management, while automated systems like conveyors and robotics reduce manual labor and increase throughput. A Inbound Logistics 2023 study found that warehouses adopting advanced technologies reported a 30% increase in operational efficiency.

Best Practices for Warehouse Safety and Security

Ensuring safety and security within the warehouse environment is paramount for maintaining smooth operations and protecting both employees and inventory. Implementing comprehensive safety protocols and robust security measures minimizes the risk of accidents, theft, and damage.

Key best practices include regular safety and security audits, comprehensive employee training programs, and the use of technologies such as surveillance cameras and access control systems. Clear communication and proper signage are also vital, including labeling hazardous materials, marking emergency exits, and providing instructions for operating machinery. Adhering to these best practices not only enhances workplace safety but also ensures compliance with regulatory standards. According to OSHA 2023 guidelines, implementing these measures can reduce workplace accidents by up to 40%.

Emerging Trends in Warehouse Management and Their Impact on Supply Chains

The landscape of warehouse management is rapidly evolving with the advent of new technologies and innovative practices. Key emerging trends include the integration of robotics and automation, the utilization of artificial intelligence (AI) and machine learning, and the adoption of cloud-based logistics systems. These advancements are poised to revolutionize warehouse operations by enhancing efficiency, increasing supply chain visibility, and reducing labor costs.

One of the most transformative trends is the use of drones for inventory management and order fulfillment. Drones can swiftly and accurately scan barcodes and RFID tags, locate products, and transport them within the warehouse, significantly reducing the time and labor required for inventory management. According to a TechRadar 2023 report, the implementation of drones in warehouses can increase inventory accuracy by 25% and reduce fulfillment times by 35%.

Another notable trend is the adoption of AI and machine learning to predict demand, optimize inventory levels, and streamline operations. These technologies enable warehouses to anticipate market fluctuations, adjust inventory proactively, and enhance decision-making processes, thereby ensuring greater resilience and agility in the supply chain.

Overall, embracing these emerging trends allows businesses to modernize their warehouse operations, improve efficiency, and maintain a competitive edge in the dynamic market landscape.

In conclusion, warehouses are indispensable to supply chain management, serving various functions from inventory storage to order fulfillment. Understanding the different types of warehouses and their specific roles enables businesses to optimize their logistics operations effectively. By focusing on efficient warehouse layout and design, implementing best practices for safety and security, and adopting emerging technologies, businesses can enhance their supply chain performance and sustain a competitive advantage in the marketplace.