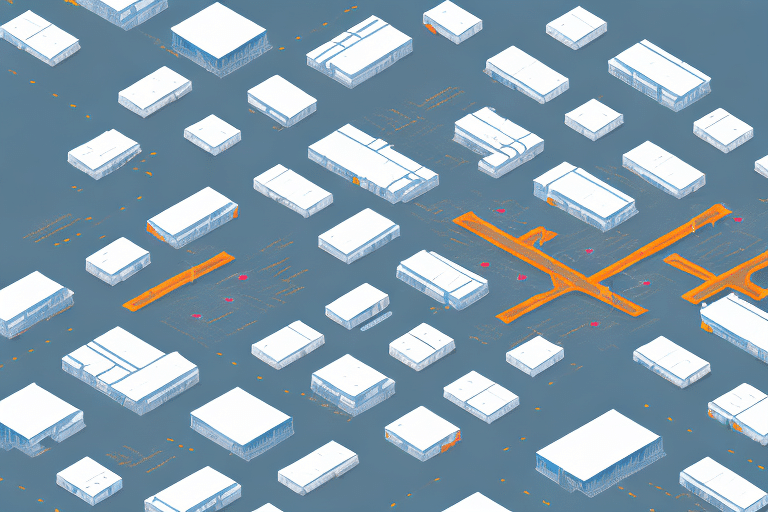

Understanding Distributed Warehousing

Distributed warehousing involves decentralizing inventory storage across multiple strategic locations rather than relying on a single, centralized warehouse. This approach enables companies to position their stock closer to customers, enhancing efficiency, reducing lead times, and minimizing transportation costs. Companies may own these warehouses or collaborate with third-party logistics providers (3PLs), allowing for flexibility and scalability in operations. The shift towards distributed warehousing is driven by increasing customer expectations for faster delivery, globalization, and advancements in logistics technology.

Key Characteristics of Distributed Warehousing

- Multiple strategically placed storage locations

- Proximity to target markets and customers

- Enhanced flexibility and scalability

- Integration with third-party logistics providers

Trends Driving the Adoption of Distributed Warehousing

The rise of e-commerce, coupled with the demand for same-day or next-day delivery services, has significantly contributed to the adoption of distributed warehousing. Additionally, globalization has necessitated the need for supply chain resilience, prompting businesses to disperse their inventory to mitigate risks associated with regional disruptions.

Benefits of Distributed Warehousing

Implementing a distributed warehousing strategy offers numerous advantages that can enhance a company's operational efficiency and customer satisfaction. These benefits include:

Improved Customer Service and Satisfaction

By situating warehouses closer to customers, businesses can fulfill orders more rapidly, leading to quicker delivery times and higher customer satisfaction. This proximity also allows for more reliable and consistent delivery performance, fostering customer loyalty.

Reduced Transportation Costs

Multiple warehouse locations reduce the distance products must travel to reach consumers, thereby lowering transportation expenses. According to a McKinsey & Company report, optimizing warehouse locations can lead to transportation cost savings of up to 10-15%.

Enhanced Supply Chain Resilience

Distributing inventory across various locations mitigates the risk of supply chain disruptions caused by natural disasters, political instability, or other unforeseen events. This diversification ensures continuity in operations and maintains service levels even when individual warehouses face challenges.

Better Inventory Management

With goods stored closer to demand centers, companies can maintain leaner inventory levels, reducing the costs associated with excess stock. Moreover, real-time inventory tracking across multiple warehouses enables more accurate demand forecasting and replenishment.

Technological Impact on Distributed Warehousing

Advanced technologies play a crucial role in optimizing distributed warehousing operations, making the system more efficient and manageable. Key technologies influencing distributed warehousing include:

Data Analytics and Artificial Intelligence

Data analytics and AI algorithms aid in demand forecasting, inventory optimization, and warehouse location planning. These technologies enable businesses to make informed decisions based on real-time data, improving overall supply chain performance.

Internet of Things (IoT)

IoT devices facilitate real-time tracking of inventory and assets within warehouses. Sensors and connected devices monitor environmental conditions, equipment performance, and workforce activities, enhancing operational efficiency and reducing latency times.

Automation and Robotics

Automation technologies, including robotics and automated guided vehicles (AGVs), streamline warehouse operations by performing repetitive tasks such as picking, packing, and sorting. This reduces human error and increases throughput.

Warehouse Management Systems (WMS)

Modern WMS software provides comprehensive tools for managing multiple warehouses, integrating inventory data, and coordinating logistics. These systems support seamless communication across the supply chain, ensuring synchronized operations.

Challenges and Considerations in Implementation

While distributed warehousing offers significant benefits, several challenges must be addressed to ensure successful implementation:

High Initial Investment

Setting up multiple warehouse locations requires substantial capital investment in facilities, technology, and workforce. Companies must carefully evaluate the return on investment to justify the upfront costs.

Complex Inventory Management

Managing inventory across multiple locations introduces complexity in tracking and coordination. Robust inventory management systems are essential to maintain accuracy and prevent stock discrepancies.

Logistical Coordination

Ensuring efficient transportation and logistics between warehouses and customers involves intricate planning. Optimizing routes and managing inter-warehouse transfers are critical to maintaining operational efficiency.

Regulatory Compliance

Operating warehouses in different regions requires adherence to local regulations and standards. Companies must navigate varying tax laws, labor regulations, and safety compliances to avoid legal complications.

Real-World Success Stories

Several leading companies have successfully leveraged distributed warehousing to enhance their operations and customer service:

Amazon

Amazon's extensive network of fulfillment centers worldwide enables the company to offer rapid delivery services, such as Prime's one-day shipping. This distributed approach allows Amazon to manage high order volumes efficiently and maintain customer satisfaction.

Zara

Zara utilizes a centralized distribution center in Spain, which serves satellite warehouses globally. This system allows for quick replenishment of stock and responsive inventory management, supporting Zara's fast-fashion business model.

Walmart

Walmart's distributed warehousing strategy includes numerous regional distribution centers that facilitate timely restocking of its vast network of retail stores. By strategically locating warehouses, Walmart minimizes transportation costs and ensures product availability.

Future Trends in Distributed Warehousing

The landscape of distributed warehousing is evolving, with emerging trends shaping its future:

Integration of Blockchain Technology

Blockchain can enhance transparency and traceability in supply chains by providing a decentralized ledger for tracking inventory movements. This technology can reduce fraud, improve data accuracy, and streamline transactions between stakeholders.

Sustainable Practices

As environmental concerns grow, companies are adopting sustainable practices in their warehousing operations. This includes using energy-efficient lighting, implementing waste reduction programs, and optimizing transportation routes to lower carbon emissions.

Advanced Robotics and AI

Continued advancements in robotics and AI will further automate warehouse processes, increasing efficiency and reducing the reliance on human labor. Intelligent systems can predict maintenance needs, optimize workflows, and adapt to changing demand patterns dynamically.

Omnichannel Fulfillment

The rise of omnichannel retailing, where businesses integrate online and offline sales channels, necessitates highly flexible distributed warehousing systems. Warehouses must support multiple fulfillment methods, including curbside pickup, same-day delivery, and direct-to-store transfers.

Conclusion

Distributed warehousing is a transformative trend in the logistics and supply chain industry, offering substantial benefits such as reduced transportation costs, enhanced supply chain resilience, and improved customer satisfaction. However, its successful implementation requires careful planning, significant investment, and robust technological support to navigate the complexities of managing multiple storage locations. As technology continues to advance and customer expectations evolve, distributed warehousing will play an increasingly vital role in enabling businesses to remain competitive in a global marketplace. Companies that effectively harness these strategies and technologies will be well-positioned to meet the demands of modern consumers and drive sustainable growth.