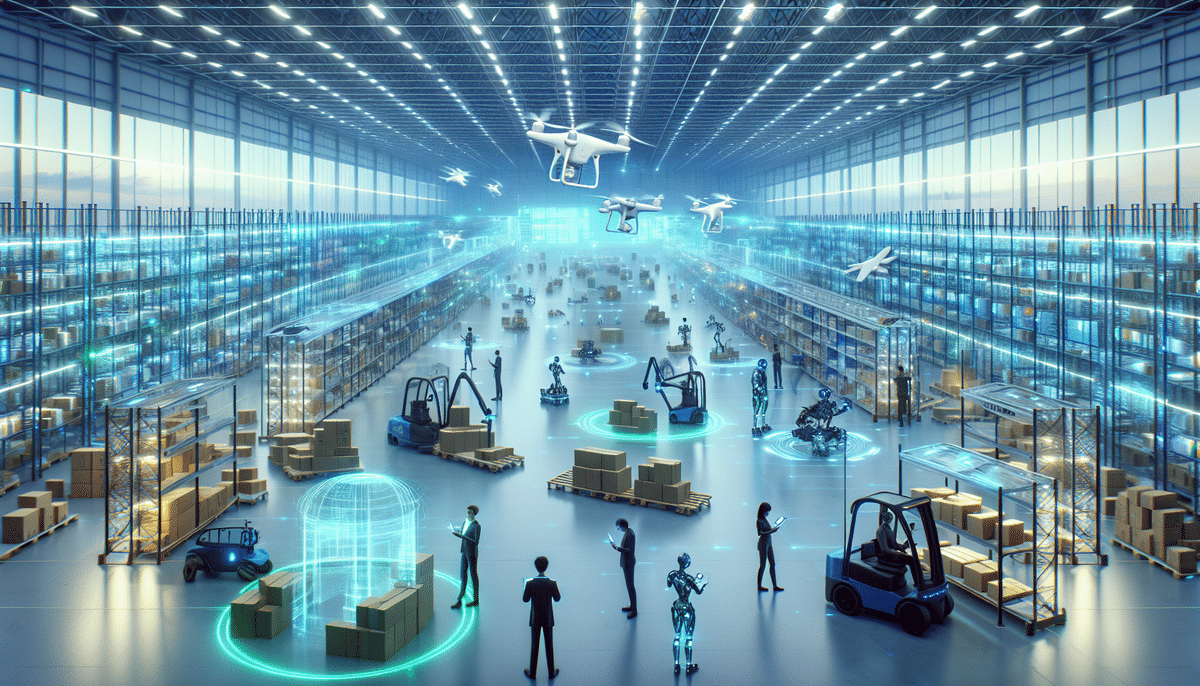

Exploring the Benefits of Future Warehouse Digitization

The modern business landscape is highly competitive and rapidly evolving. To remain relevant and maintain a competitive edge, businesses must adopt digital solutions. In recent years, the digitization of warehousing has gained significant traction due to the numerous advantages it offers. According to a Forbes report, warehouse digitization can increase operational efficiency by up to 30%. This article delves into the importance of embracing digital solutions in modern warehousing and the myriad benefits of warehouse digitization.

The Importance of Adopting Digital Solutions in Modern Warehousing

The traditional approach to warehousing, which relied heavily on paper-based records, is now considered outdated. Paper records are susceptible to human error, are time-consuming to manage, and lack scalability. According to a study by McKinsey & Company, digitization in warehousing can reduce error rates by up to 50%. Digitization addresses these challenges by enabling real-time data recording and processing. This real-time data allows businesses to:

- Optimize warehouse operations

- Accurately track inventory

- Enhance customer satisfaction

Moreover, digital solutions facilitate the implementation of automation and robotics, significantly improving efficiency and reducing labor costs. Automated systems handle large volumes of inventory with minimal human intervention, increasing operational speed and reducing the risk of errors and accidents. Additionally, businesses can track the movement of goods in real-time, enhancing supply chain visibility and enabling better decision-making.

How Warehouse Digitization Can Improve Operational Efficiency

Technologies such as RFID tags, barcode systems, and sensors play a pivotal role in enhancing operational efficiency within warehouses. According to the Global Data report, the adoption of these digital tools can reduce turnaround times by up to 40%. These digital tools help automate processes, reduce turnaround times, and increase accuracy in inventory management. The adoption of automated guided vehicles (AGVs), drones, and robots can streamline tasks like transporting, packing, and unloading goods, leading to:

- Reduced labor costs

- Maximized profits

- Increased operational speed

Additionally, the ability to track and analyze data in real-time allows businesses to monitor inventory levels, track goods movement, and identify areas for operational improvement. This data-driven approach leads to informed decision-making, optimizing processes, and boosting overall productivity.

Warehouse digitization also enhances workplace safety by automating tasks and reducing the need for manual labor, thereby minimizing the risk of accidents and injuries. Digital solutions like sensors and cameras can monitor the warehouse environment, detect potential hazards, and allow for swift corrective actions.

The Role of Automation in Streamlining Warehouse Operations

Automation in warehousing involves using digitized applications and machinery to perform repetitive tasks, thereby increasing operational efficiency. Key benefits of warehouse automation include:

- Reduction of errors

- Optimal utilization of resources

- Decreased downtime

Implementing a Warehouse Management System (WMS) further streamlines operations by providing real-time data insights, enabling data-driven decision-making.

Automation also reduces labor costs by minimizing the number of employees needed for repetitive tasks like picking and packing. This not only saves on labor expenses but also lowers the risk of workplace injuries.

Moreover, automated systems can handle a larger volume of orders efficiently and accurately, which is particularly beneficial during peak seasons or unexpected demand surges.

Reducing Human Error in Warehousing Through Digitization

Managing inventory manually in traditional warehouses is prone to errors, including misreading records, inventory mismanagement, and inaccuracies in picking and packing. Digitization addresses these issues by automating processes and reducing human intervention. Technologies such as barcode scanning, RFID tagging, and automated picking systems help minimize errors and optimize warehouse operations.

Real-time inventory tracking is another significant advantage of digitization. Businesses can monitor inventory levels, track goods movement, and identify potential issues before they escalate. According to the Supply Chain Digital, enhanced visibility allows for informed decision-making, waste reduction, and improved overall efficiency.

Integrating warehouse operations with other business systems, such as Enterprise Resource Planning (ERP) software, further streamlines processes, reduces effort duplication, and enhances data accuracy. This integration provides valuable insights into overall business performance, facilitating data-driven decisions and improving profitability.

Enhancing Inventory Management with Digital Technologies

Digital technologies have transformed inventory management by enabling real-time tracking and management of inventory levels. Tools like WMS, barcode scanners, and RFID tags allow businesses to:

- Accurately track inventory

- Monitor inventory location and status

- Reduce holding costs

- Increase profitability

Moreover, IoT sensors and devices provide businesses with real-time information on inventory locations and statuses, enhancing transparency and control. According to a Forrester study, integrating IoT in inventory management can lead to a 25% increase in inventory accuracy.

Digital technologies also aid in demand forecasting and inventory optimization. By analyzing historical data and employing predictive analytics, businesses can forecast demand accurately and adjust inventory levels accordingly. This helps avoid stockouts and overstocking, leading to reduced waste and improved customer satisfaction.

The Impact of Data Analytics on Warehouse Optimization

Data analytics is integral to optimizing warehouse operations. It allows businesses to:

- Analyze performance metrics

- Optimize resource utilization

- Enhance customer satisfaction

With data analytics, businesses can predict trends, anticipate demand spikes, and optimize inventory management. Insights into customer behavior enable businesses to fine-tune their operations, leading to increased profitability. A report by Gartner highlights that data-driven warehouses can improve operational efficiency by up to 20%.

For instance, analyzing data on inventory levels, order processing times, and shipping durations helps identify inefficiencies in the supply chain. This information can be used to optimize shipping routes, reducing transportation costs and improving delivery times.

Data analytics also plays a crucial role in quality control. By examining data on product defects and customer complaints, businesses can identify patterns and trends, improving product quality and reducing return rates. This leads to higher customer satisfaction and loyalty, along with cost savings from fewer returns and warranty claims.

Benefits of Real-Time Tracking and Traceability in Warehousing

Real-time tracking and traceability are essential components of modern warehouse digitization. They enable businesses to:

- Monitor inventory levels continuously

- Track goods in transit

- Gain visibility into goods movement across various touchpoints

- Meet regulatory requirements

- Effectively manage product recalls

Implementing real-time tracking and traceability solutions improves operational efficiency, optimizes workflows, and enhances customer satisfaction by providing accurate and timely information. According to the SAS Institute, real-time tracking can enhance supply chain visibility by 35%, leading to better inventory management and reduced lead times.

Improving Customer Satisfaction with Digital Warehousing Solutions

Digital warehousing solutions play a pivotal role in enhancing customer satisfaction by:

- Improving order accuracy

- Reducing order processing times

- Speeding up delivery times

- Providing real-time inventory tracking

With accurate information on product availability and expected delivery times, businesses can offer better service, leading to increased sales and revenue. A study by Oracle found that companies implementing digital warehousing solutions experienced a 15% increase in customer satisfaction scores.

Reducing Costs and Maximizing Profits through Digitization in Warehousing

Digitizing warehousing operations offers businesses substantial cost reductions by:

- Automating processes

- Reducing errors

- Cutting labor costs

- Optimizing inventory levels

These cost savings translate into increased profitability. Additionally, digital solutions enhance forecasting accuracy, minimize inventory holding costs, and help achieve optimal inventory levels. According to PwC, companies can achieve up to a 25% reduction in operational costs through effective warehouse digitization.

By leveraging digital solutions, businesses gain a competitive edge, optimize operations, and maximize profits.

The Future of Warehousing: A Look into Digital Innovations and Trends

The future of warehousing is undeniably digital. Emerging digital innovations and trends that are set to shape the future include:

- Internet of Things (IoT): Enhances connectivity and data sharing across warehouse operations.

- Augmented Reality (AR): Improves picking accuracy and training processes.

- Voice-Activated Technologies: Streamlines communication and task execution.

- Artificial Intelligence (AI): Enables predictive maintenance and advanced data analytics.

- Blockchain: Enhances traceability and security in the supply chain.

As these technologies evolve, they will play increasingly significant roles in optimizing warehouse operations, reducing costs, and enhancing customer satisfaction. A TechRadar article predicts that AI and machine learning will drive the next wave of innovations in warehouse management, leading to smarter and more efficient operations.

Overcoming Challenges in Implementing Digital Solutions in Warehousing

Adopting digital solutions in warehousing can present several challenges, including:

- Integrating new technologies with existing systems

- Training employees to use new systems

- Adapting to new workflows

- Initial implementation costs

However, businesses can overcome these challenges through careful planning, pilot testing, and ongoing employee training and support. Effective change management strategies ensure smooth adoption and optimization of digital solutions. According to a Harvard Business Review article, companies that invest in comprehensive training programs and phased implementation plans are more likely to succeed in their digital transformation efforts.

The Importance of Cybersecurity in the Era of Digital Warehousing

As warehouses become more digitized, cybersecurity becomes critically important. Cybersecurity breaches can result in significant financial losses and damage a company's reputation. To safeguard against such threats, businesses should:

- Adopt secure communication protocols

- Implement robust access control systems

- Provide comprehensive cybersecurity training to employees

- Regularly update and patch software systems

Investing in cybersecurity measures is essential to protect digital assets and maintain trust with customers and stakeholders. The CSO Online emphasizes that proactive cybersecurity strategies can prevent data breaches and ensure the integrity of warehouse management systems.

Success Stories: Companies that Have Benefited from Warehouse Digitization

Many companies have reaped substantial benefits from warehouse digitization. For example, Walmart has implemented automation technologies in its warehouses to boost efficiency and reduce costs, enabling same-day and next-day delivery services. These advancements have significantly enhanced customer experiences, demonstrating the tangible benefits of digital solutions in warehousing. Similarly, Amazon utilizes advanced robotics and AI-driven systems to manage its vast inventory, resulting in faster order fulfillment and reduced operational costs.

By leveraging digital technologies, businesses can streamline operations, optimize efficiency, and elevate customer satisfaction.

Choosing the Right Digital Tools for Your Warehouse: A Guide for Business Owners

Selecting the appropriate digital tools for your warehouse can be daunting due to the vast array of options and system complexities. Business owners can simplify this process by:

- Collaborating with experienced vendors

- Conducting thorough due diligence

- Evaluating systems through pilot tests

- Ensuring scalability and growth potential

- Considering integration capabilities with existing systems

Choosing the right digital tools tailored to specific business needs is crucial for optimizing warehouse operations and facilitating future growth. According to Software Advice, businesses should prioritize features that align with their operational goals, such as inventory accuracy, ease of use, and reporting capabilities.

Conclusion

Warehouse digitization is essential for businesses aiming to stay competitive and optimize their operations. By adopting digital solutions, businesses can:

- Increase operational efficiency

- Reduce errors

- Cut costs

- Enhance customer satisfaction

The future of warehousing is digital, and businesses that embrace these solutions will maintain a competitive edge, stay ahead of industry trends, and maximize profitability.