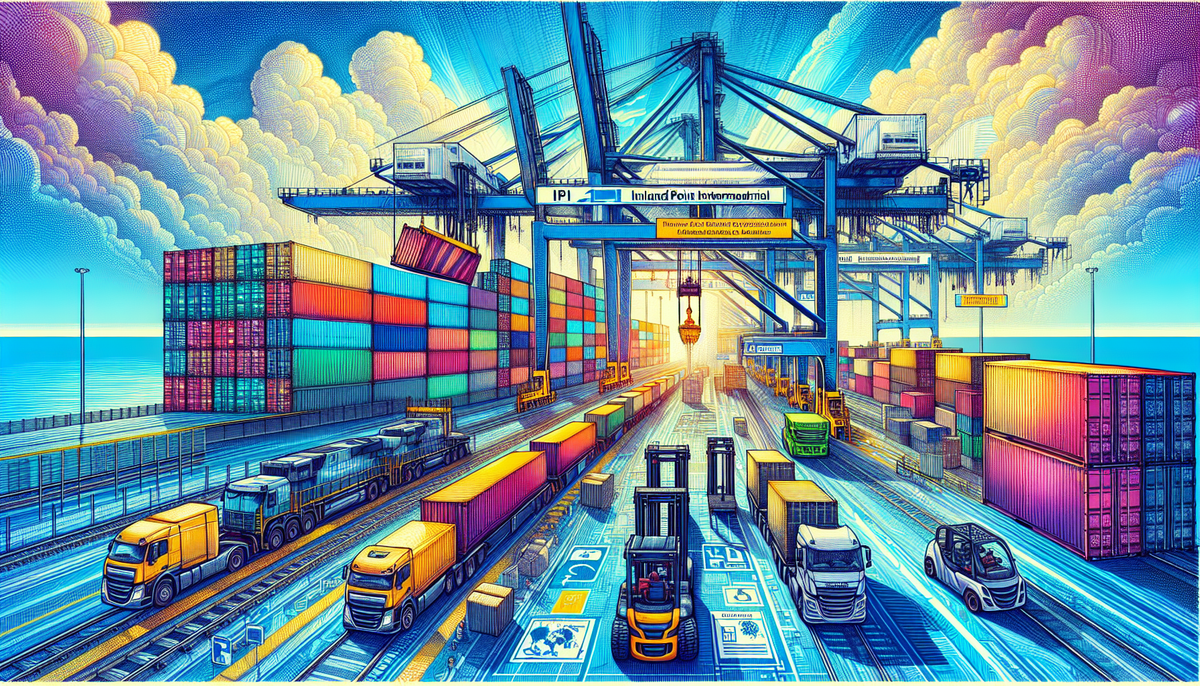

Introduction to Inland Point Intermodal (IPI) in Modern Supply Chains

In today's dynamic supply chain and logistics landscape, the efficient and cost-effective transportation of goods is paramount. One transportation solution gaining significant traction is Inland Point Intermodal (IPI). This comprehensive guide delves into IPI, exploring its advantages, challenges, environmental benefits, and its strategic implementation within supply chains. Let's explore everything you need to know about IPI.

What is Inland Point Intermodal (IPI) and How Does it Work?

Inland Point Intermodal (IPI) is a sophisticated form of intermodal transportation that facilitates the movement of goods between two points using multiple transportation modes, including trucks, trains, and ships. Primarily utilized for long-distance shipments exceeding 600 miles, IPI leverages the strengths of each transportation mode to optimize efficiency and cost.

Operational Workflow of IPI

- Initial Transport: Goods are transported by truck to a designated rail yard.

- Rail Transportation: At the rail yard, goods are loaded onto trains for the bulk of the journey.

- Final Delivery: Upon reaching an inland terminal near the destination, goods are transferred back to trucks for final delivery.

IPI stands out as a cost-effective and environmentally friendly option by reducing the number of trucks on highways, thereby decreasing carbon emissions and enhancing transit efficiency. According to the Bureau of Transportation Statistics, intermodal transport can reduce transportation costs by up to 20% compared to traditional trucking.

The History and Evolution of IPI in Logistics

IPI's roots trace back several decades, evolving alongside advancements in technology and infrastructure. The mid-20th century saw the rise of the interstate highway system in the United States, which boosted trucking and initially marginalized rail transport. However, the 1980s brought significant changes with the deregulation of the railroad industry and technological innovations, including improved tracking and communication systems, making intermodal transportation more viable and efficient.

Key Milestones in IPI Development

- 1980s: Deregulation of railroads revitalizes intermodal transport.

- 1990s: Technological advancements improve tracking and communication.

- 2000s: Growth in global trade amplifies the need for efficient intermodal solutions.

- 2010s: Sustainable logistics become a priority, driving further adoption of IPI.

Today, IPI is recognized as a sustainable and cost-effective alternative to traditional long-distance trucking, supported by data from the Trains Magazine, highlighting a consistent rise in intermodal shipments over the past decade.

The Role of IPI in Modern Supply Chain Management

In an era marked by globalization and increasing transportation complexities, IPI plays a pivotal role in modern supply chain management. By integrating multiple transportation modes, IPI offers significant flexibility, efficiency, and cost savings to shippers.

Benefits of IPI in Supply Chains

- Flexibility: Multiple transportation options allow for adaptable routing.

- Efficiency: Streamlined operations reduce transit times.

- Cost Savings: Lower transportation costs compared to exclusive trucking.

- Environmental Impact: Reduced carbon emissions contribute to sustainability goals.

Moreover, IPI helps mitigate risks associated with transportation disruptions, such as natural disasters or labor strikes. By diversifying transportation modes, shippers can maintain supply chain resilience. The McKinsey & Company report emphasizes the importance of multi-modal strategies like IPI for resilient supply chains.

Advantages of Using IPI for Intermodal Transportation

IPI presents several advantages that make it an attractive option for shippers:

- Cost Efficiency: IPI often results in lower transportation costs by leveraging the economical nature of rail transport for long distances.

- Enhanced Security: Fewer handling points reduce the risk of cargo theft and damage.

- Reduced Highway Congestion: Fewer trucks on the road alleviate traffic and wear on infrastructure.

- Environmental Sustainability: Lower carbon emissions contribute to corporate sustainability initiatives.

- Increased Capacity Flexibility: Ability to handle larger volumes of cargo through the use of standardized containers.

For instance, studies from the Environmental Protection Agency indicate that intermodal transport can reduce greenhouse gas emissions by up to 45% compared to conventional trucking.

How IPI Streamlines Operations and Reduces Costs in Logistics

IPI optimizes logistics operations by minimizing the number of touchpoints required to move goods, thereby reducing handling and transfer costs. The integration of rail and truck transportation not only improves shipping times but also lowers expenses related to fuel, maintenance, and labor.

Operational Efficiencies Achieved Through IPI

- Reduced Handling: Fewer transfers between transportation modes decrease the likelihood of delays and damage.

- Fuel Savings: Trains are more fuel-efficient over long distances compared to trucks.

- Maintenance Costs: Fewer wear and tear instances due to optimized transportation modes.

Advanced tracking and monitoring systems inherent in IPI provide real-time visibility into shipment status, allowing for data-driven decision-making. This transparency reduces the risk of lost or damaged goods and enhances overall supply chain efficiency, as highlighted by the Supply Chain Digital.

Case Studies: Companies Thriving with IPI

Numerous companies have successfully integrated IPI into their supply chain strategies, reaping substantial benefits:

E-Commerce Giant Reduces Costs Significantly

A leading e-commerce company transitioned to IPI, resulting in a 40% reduction in transportation costs. This shift enabled faster delivery times and enhanced customer satisfaction.

Manufacturing Firm Enhances Inventory Management

A manufacturing company incorporated IPI and achieved a 25% reduction in inventory carrying costs through improved real-time tracking and reduced lead times, as reported in their annual supply chain review.

These examples underscore IPI's potential to drive efficiency and cost savings across various industries.

The Future of IPI and Its Impact on the Logistics Industry

The outlook for IPI is promising, with expectations of continued growth and increased adoption in the logistics sector. Emerging technologies such as autonomous vehicles and drones may further transform IPI, enhancing its efficiency and scalability.

Technological Innovations Shaping IPI's Future

- Autonomous Trucks: Enhanced automation can streamline the final mile delivery phase.

- Drones: Potential for rapid last-mile deliveries in remote areas.

- Advanced Data Analytics: Improved decision-making through predictive analytics and IoT integration.

Environmental considerations will continue to drive IPI adoption. With increasing regulatory pressures and corporate commitments to sustainability, IPI's role as a greener transportation option will become even more critical, supported by insights from the World Bank.

Implementing IPI into Your Supply Chain Strategy

To successfully incorporate IPI into your supply chain, meticulous planning and strategic execution are essential. Here are key steps to guide the implementation process:

Steps to Implement IPI

- Evaluate Transportation Needs: Assess whether IPI aligns with your shipping volumes, destinations, and cost objectives.

- Select a Reliable IPI Provider: Partner with providers who have a robust network and proven expertise in intermodal transport.

- Develop Contingency Plans: Prepare for potential challenges such as infrastructure delays or regulatory changes.

- Integrate Technology: Utilize advanced tracking systems to enhance visibility and control over shipments.

- Train Your Team: Ensure that your logistics personnel are well-versed in IPI operations and best practices.

Cost-effectiveness is a critical factor. Shippers should conduct a thorough cost-benefit analysis to compare IPI with other transportation options, considering potential savings from reduced fuel and maintenance expenses.

Overcoming Common Challenges in IPI Adoption

While IPI offers numerous advantages, its adoption comes with challenges that must be addressed to ensure seamless integration:

- Infrastructure Limitations: Adequate rail and terminal facilities are essential for efficient operations.

- Route-Specific Restrictions: Certain routes may have regulatory or logistical constraints affecting IPI viability.

- Increased Lead Times: Coordination between multiple transportation modes can sometimes lead to longer transit times.

Addressing these challenges requires collaboration among shippers, transportation providers, and policymakers. Investing in infrastructure improvements and leveraging technology can mitigate many of these issues, as suggested by the U.S. Department of Transportation.

Comparing IPI to Other Intermodal Transportation Options

IPI is just one of several intermodal transportation options available to shippers. It’s important to compare IPI with alternatives to determine the best fit for your needs:

- Standard Intermodal: Utilizes conventional rail and truck services without the specialized inland point terminals.

- Maritime Intermodal: Incorporates shipping containers transported via ships, suitable for international shipments.

- Air Intermodal: Combines air freight with ground transportation, ideal for time-sensitive goods.

IPI distinguishes itself through its focus on inland points, providing enhanced flexibility and access to remote locations. Inbound Logistics offers a detailed comparison of these options, highlighting IPI's unique benefits in cost and sustainability.

Best Practices for Maximizing IPI Benefits in Your Supply Chain

To fully harness the advantages of IPI, adopting best practices is crucial:

- Collaborate with Experts: Work closely with experienced IPI providers to tailor solutions to your specific needs.

- Leverage Technology: Implement advanced tracking and data analytics to monitor and optimize your supply chain.

- Continuous Improvement: Regularly assess and refine your IPI processes to enhance efficiency and cost savings.

- Integrate Sustainability Goals: Align IPI operations with your organization's environmental objectives.

By following these practices, businesses can ensure that IPI integration delivers maximum value and supports long-term supply chain resilience.

The Environmental Benefits of Using IPI for Sustainable Logistics

IPI significantly contributes to environmental sustainability by reducing carbon emissions and improving air quality. By combining rail and truck transportation, IPI minimizes the number of trucks on highways, thus lowering greenhouse gas emissions and alleviating traffic congestion.

Key Environmental Advantages

- Lower Carbon Footprint: Rail transport is more fuel-efficient than road transport, leading to reduced emissions.

- Reduced Traffic Congestion: Fewer trucks on the road decrease highway congestion and related emissions.

- Enhanced Sustainability: Aligns with corporate sustainability goals and regulatory requirements.

According to the Environmental Protection Agency, intermodal transportation methods like IPI can lower greenhouse gas emissions by up to 30% compared to exclusive truck transport.

Key Considerations When Choosing an IPI Provider

Selecting the right IPI provider is critical for successful integration into your supply chain. Here are key factors to consider:

- Experience and Expertise: Choose providers with a proven track record in intermodal transportation.

- Comprehensive Services: Ensure the provider offers all necessary transportation modes and logistical support.

- Infrastructure and Network: A robust network of rail yards and inland terminals enhances efficiency.

- Technology Capabilities: Advanced tracking and data analytics tools are essential for real-time visibility.

- Customer Support: Reliable and responsive customer service ensures smooth operations.

Collaborating with providers like those reviewed by Logistics Management can help identify the best fit for your specific supply chain needs.

The Impact of COVID-19 on IPI Adoption and Usage in Logistics

The COVID-19 pandemic profoundly affected the logistics industry, prompting many shippers to explore alternative transportation options like IPI. The pandemic underscored the need for resilient and flexible supply chains, driving increased adoption of IPI as a sustainable and cost-effective solution.

How COVID-19 Influenced IPI Trends

- Increased Demand for Resilience: IPI offers diversified transportation modes, enhancing supply chain resilience.

- Cost Management: Economic uncertainties pushed companies to seek cost-effective transportation alternatives.

- Sustainability Focus: The pandemic heightened awareness of environmental impacts, boosting interest in greener transportation options.

As reported by Forbes, many businesses that adopted IPI during the pandemic are likely to continue leveraging this transportation method to maintain flexibility and sustainability in their supply chains.