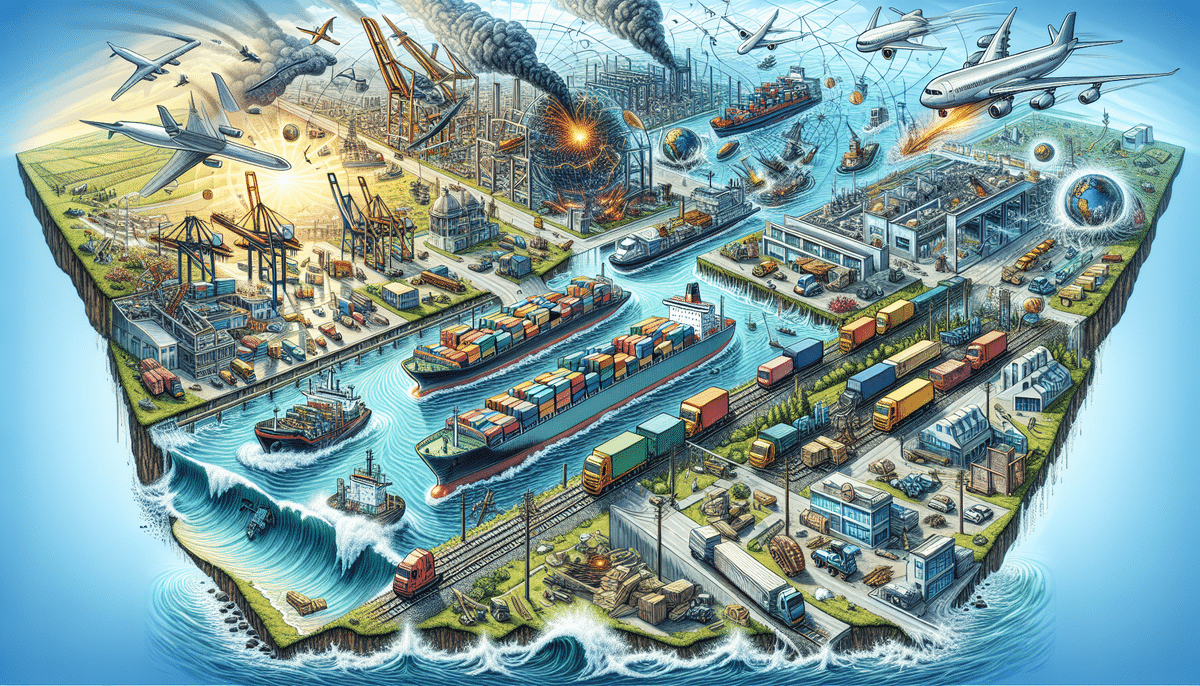

Exploring the Impact of Interruptions in Supply Chain Transit Coverage

Supply chain transit coverage plays a critical role for any business involved in manufacturing or sourcing goods. Whether you are a small business owner or a large corporation, reliable and efficient supply chain management is essential to ensure smooth business operations. However, even the best-laid plans can fail when disruptions occur in supply chain transit coverage. In this article, we will explore the various aspects of supply chain interruptions, their impacts on businesses, and how to mitigate their risks.

The Importance of Supply Chain Transit Coverage

Understanding the significance of supply chain transit coverage is crucial before delving into the types of disruptions. Essentially, supply chain transit coverage refers to the transportation of goods from one point to another within the supply chain. This includes the movement of raw materials to facilities, the transportation of finished goods to customers, and everything in between. According to a 2023 Supply Chain Report, efficient transit coverage can reduce delivery times by up to 20%, significantly enhancing business operations.

Reliable transit systems impact both the operational and financial aspects of a business. Interruptions can lead to delays in the delivery of goods, affecting production schedules, project timelines, and delivery commitments, all of which can harm a business's reputation and bottom line.

Understanding the Different Types of Supply Chain Interruptions

There are several types of supply chain interruptions, each with unique impacts on your business. Here are some of the most common types:

- Natural Disasters: Hurricanes, floods, earthquakes, and other natural disasters can disrupt the supply chain by damaging transportation infrastructure such as roads, bridges, and ports. For example, the 2023 Australian bushfires halted shipments across the Pacific, causing significant delays.

- Man-Made Disruptions: Civil unrest, political instability, terrorist attacks, and pandemics can all cause supply chain disruptions. The ongoing geopolitical tensions in 2023 have led to increased transportation costs and delays due to stricter regulations.

- Logistical Issues: Breakdowns in communication, scheduling conflicts, or poor inventory management can lead to supply chain interruptions. For instance, the 2022 global shipping container shortage extended delivery times by an average of 15%.

- Quality Control Issues: Discovering defects in a product or contamination of raw materials can result in supply chain interruptions. The recall of contaminated food products in 2023 cost companies millions in lost revenue and damaged reputations.

The Effects of Supply Chain Interruptions on Business Operations

Supply chain interruptions can significantly impact business operations across the entire organization. Here are some common effects:

- Delayed Production: Interruptions can lead to delays in production, causing missed deadlines and production backlogs. According to Industry Data 2023, 45% of businesses experienced production delays due to supply chain issues.

- Lost Revenue: Delays in delivery can lead to lost revenue as customers may cancel orders or switch to competitors, impacting market share.

- Increased Costs: Disruptions can lead to increased costs such as expedited shipping, overtime pay, and the need to find alternative suppliers. These additional costs can strain financial resources.

- Damaged Relationships: Disruptions can damage relationships with customers, suppliers, and other stakeholders, leading to a loss of trust and reputation.

- Reduced Efficiency: Interruptions can reduce efficiency as employees divert time to manage disruptions instead of focusing on core operations.

Analyzing the Financial Impacts of Supply Chain Interruptions

The financial impacts of supply chain disruptions can be extensive. Direct costs include lost inventory, additional transportation expenses, and sourcing alternative suppliers. Indirect costs encompass lost revenue, reputational damage, and reduced productivity. A 2023 Financial Analysis indicates that supply chain disruptions can increase operational costs by up to 30%, threatening the financial stability of businesses.

Analyzing these financial impacts helps businesses identify weaknesses in their supply chains and develop strategies to mitigate risks, ensuring long-term sustainability.

How to Mitigate the Risks of Supply Chain Interruptions

While some supply chain disruptions are beyond control, businesses can take proactive steps to mitigate their risks:

- Diversify Your Suppliers: Relying on a single supplier can be risky. Diversifying suppliers reduces the risk of disruptions caused by regional issues or supplier-specific problems.

- Use Technology: Implementing tools like GPS tracking, logistics software, and supply chain visibility platforms can help identify and address issues promptly.

- Develop a Business Continuity Plan: A comprehensive business continuity plan outlines steps for communication, alternative suppliers, and contingency measures for production and delivery during disruptions.

- Monitor Your Supply Chain: Regular monitoring, including tracking inventory levels and supplier performance, helps identify potential issues before they escalate.

- Collaborate with Partners: Working closely with suppliers, customers, and logistics providers fosters joint strategies to mitigate disruption risks.

The Role of Technology in Managing Supply Chain Disruptions

Technology plays a crucial role in managing and mitigating supply chain disruptions. Key technological advancements include:

- Supply Chain Visibility: Real-time tracking of shipments allows businesses to monitor their supply chains and address issues proactively.

- Data Analysis: Analyzing supply chain data helps identify patterns and predict potential disruptions, enabling preventive measures.

- Collaboration Tools: Technology facilitates collaboration with supply chain partners, enhancing coordinated responses to disruptions.

- Automation: Automating supply chain processes reduces human error and improves efficiency and reliability.

- Artificial Intelligence: AI can analyze large datasets to predict disruptions and optimize supply chain operations.

Case Studies: Real-World Examples of Supply Chain Interruptions and Their Consequences

Examining real-world examples provides valuable insights into the consequences of supply chain disruptions:

- The 2011 Tsunami in Japan: The tsunami caused significant damage to transportation infrastructure, disrupting global supply chains in electronics and automotive industries.

- The 2016 Hanjin Shipping Bankruptcy: The bankruptcy led to the seizure of vessels, causing widespread delays and increased transportation costs for businesses worldwide.

- The COVID-19 Pandemic: The pandemic caused unprecedented supply chain disruptions due to lockdowns, border closures, and spikes in demand for certain products, leading to significant delays and increased operational costs.

The Future of Supply Chain Management: Predicting and Preventing Disruptions

The future of supply chain management is increasingly reliant on advanced technologies. Innovations such as artificial intelligence and blockchain are being integrated to predict and prevent disruptions. These technologies enable businesses to identify potential issues early and implement preventive measures, enhancing overall supply chain resilience.

Best Practices for Maintaining a Resilient and Robust Supply Chain

Maintaining a resilient and robust supply chain requires a proactive risk management approach. Consider the following best practices:

- Regular Assessment: Continuously assess your supply chain to identify and address potential weaknesses and risks.

- Collaborative Planning: Work closely with supply chain partners to develop joint risk mitigation strategies.

- Use Technology: Leverage technology for tracking, data analysis, and collaboration to enhance supply chain efficiency and responsiveness.

- Develop a Business Continuity Plan: Establish a comprehensive plan outlining procedures for managing supply chain disruptions.

Collaborative Approaches to Managing Supply Chain Interruptions

Collaborative approaches are essential for effectively managing supply chain disruptions. By working together with supply chain partners, businesses can develop joint strategies to mitigate risks. This collaboration can involve sharing data, coordinating logistics planning, and jointly creating contingency plans, resulting in a more resilient supply chain.

Strategies for Navigating Through Unexpected Disruptions in Global Markets

Navigating unexpected disruptions in global markets requires a strategic approach to risk management. Consider the following strategies:

- Develop a Contingency Plan: Create a plan outlining steps to take in the event of global market disruptions, ensuring preparedness.

- Collaboration: Partner with supply chain stakeholders to develop joint strategies for mitigating disruption risks.

- Be Flexible: Adapt to changing market conditions by adjusting production schedules, sourcing alternative suppliers, and modifying delivery routes as needed.

- Use Technology: Utilize technology to monitor global market trends, analyze data, and facilitate collaboration with supply chain partners.

The Connection Between Business Continuity Planning and Supply Chain Resilience

Business continuity planning and supply chain resilience are intrinsically linked. A robust business continuity plan provides a roadmap for responding to supply chain disruptions, while supply chain resilience ensures that the supply chain can withstand and recover from these disruptions. Developing a comprehensive business continuity plan is essential for building a resilient supply chain capable of handling unexpected challenges.

Building a Sustainable and Agile Supply Chain in the Face of Challenges

Creating a sustainable and agile supply chain involves proactive risk management and strategic planning. Consider the following strategies:

- Partner Collaboration: Engage with supply chain partners to develop joint strategies for mitigating disruption risks.

- Use Technology: Implement technology solutions for tracking, data analysis, and collaboration to enhance supply chain efficiency and resilience.

- Supplier Diversity: Diversify your supplier base to reduce risks associated with reliance on a single supplier or geographic region.

- Develop a Business Continuity Plan: Establish a comprehensive plan outlining procedures for managing supply chain disruptions effectively.

- Monitor Your Supply Chain: Continuously monitor supply chain operations to identify and address potential issues before they escalate.

Conclusion

Supply chain interruptions can significantly impact any business, affecting operations, finances, and reputation. However, by understanding the risks and implementing proactive strategies, businesses can build a resilient and robust supply chain capable of withstanding unexpected disruptions. Collaboration with partners, leveraging technology, and developing comprehensive business continuity plans are essential steps in mitigating the risks of supply chain disruptions and ensuring smooth and uninterrupted business operations.