Exploring the Latest Warehouse Technologies for Increased Efficiency

In today’s fast-paced business landscape, companies must continuously strive to maximize efficiency in all aspects of their operations. This is especially true for businesses that manage large warehouses, where even slight improvements in productivity and accuracy can significantly impact the bottom line. To achieve this, logistics and supply chain managers are turning to the latest warehouse technologies to enhance efficiency and optimize workflow. In this article, we will explore the most recent advancements in warehouse technology and how they can help businesses increase efficiency.

Understanding the Importance of Warehouse Efficiency in the Modern Business Landscape

Efficient warehouse management is crucial for businesses aiming to stay competitive in today’s market. Technological advancements in warehouse management have streamlined workflows, optimized inventory management, and increased throughput, leading to a more agile and responsive supply chain. By embracing the latest technologies, businesses can reduce costs, boost productivity, and better meet customer demands.

One of the key benefits of efficient warehouse management is the ability to minimize errors and improve accuracy. With automated systems and real-time data tracking, businesses can reduce the risk of human error and ensure that inventory is always up-to-date. This not only enhances the accuracy of order fulfillment but also aids businesses in making informed decisions about inventory management and purchasing. According to a McKinsey report, companies that implement advanced warehouse technologies can see a productivity increase of up to 30%.

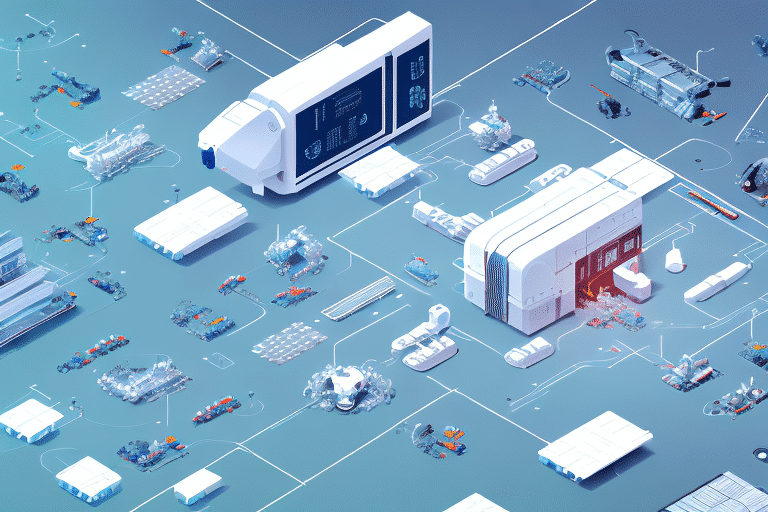

The Evolution of Warehouse Technologies: From Manual to Automated Systems

The evolution of warehouse technologies has been remarkable, transitioning from manual, labor-intensive systems to highly automated solutions. Initially, warehouses relied on manual labor for tasks such as moving and storing goods. Over time, technological advancements introduced automated systems like conveyor belts, Automated Storage and Retrieval Systems (AS/RS), and robotics. These innovations have revolutionized the storage and movement of goods, significantly reducing costs, improving accuracy, and increasing overall efficiency.

One of the latest advancements in warehouse technology is the use of drones for inventory management and order fulfillment. Drones can quickly and accurately scan barcodes and RFID tags, locate products, and transport them to designated areas. This technology has the potential to further enhance efficiency and reduce operational costs in warehouse settings. However, challenges such as regulatory restrictions and the need for specialized training and equipment still need to be addressed.

Top Emerging Technologies in Warehousing: Robotics, IoT, and AI

Robotics, the Internet of Things (IoT), and Artificial Intelligence (AI) are some of the most exciting emerging technologies in warehousing today. Robotics, in particular, is rapidly gaining traction as companies seek to automate manual pick-and-place tasks, reduce errors, and improve speed. IoT technology enables real-time monitoring of warehouse operations, providing valuable insights into inventory management and supply chain optimization. Meanwhile, AI can be utilized to automate predictive analytics, enable dynamic slotting, and optimize routing, among other applications.

One of the primary benefits of using robotics in warehousing is the ability to increase efficiency and productivity. With robots handling repetitive and time-consuming tasks, human workers can focus on more complex and value-added activities. Additionally, robots can operate around the clock, reducing the need for shift work and increasing overall output.

Another emerging technology in warehousing is blockchain. By utilizing a decentralized ledger system, blockchain can provide greater transparency and traceability in the supply chain. This enhances inventory management, reduces fraud, and builds customer trust. As blockchain technology continues to evolve, it is expected to become an increasingly important tool for warehousing and logistics.

How Robotics is Revolutionizing Warehouse Operations and Efficiency

Robotic systems are becoming increasingly prevalent in modern warehouses. These systems can perform tasks such as item picking, sorting, and palletizing with remarkable speed and accuracy, allowing human workers to focus on more complex responsibilities. Furthermore, robotic systems can operate continuously, enhancing throughput and overall efficiency.

One of the key advantages of using robotic systems in warehouses is their ability to collect and analyze data. By tracking inventory levels, order patterns, and other metrics, these systems can optimize warehouse layouts and workflows to minimize wasted time and resources. Additionally, the data collected by robotic systems can be used to identify areas for improvement and inform future decision-making processes.

According to a study by IBISWorld, the integration of robotics in warehousing can lead to a 15-20% increase in operational efficiency, highlighting the significant impact of this technology on modern supply chains.

Harnessing the Power of IoT for Better Inventory Management and Tracking

IoT technology has the potential to revolutionize inventory management and tracking by providing real-time data and analytics that inform decision-making. For example, RFID (Radio Frequency Identification) technology can track items as they move through the warehouse, offering valuable data on inventory levels, movement patterns, and bottlenecks. This information can be used to optimize warehouse layout, improve picking accuracy, and reduce the risk of stockouts and overstocking.

In addition to RFID technology, IoT sensors can monitor environmental conditions such as temperature and humidity, which is particularly important for perishable goods. This data ensures that products are stored under optimal conditions, reducing waste and maintaining product quality.

Furthermore, IoT technology extends beyond the warehouse, enabling inventory tracking during transportation and delivery. This enhances visibility and control over the entire supply chain, reducing the risk of lost or stolen goods and improving delivery times. According to a Forbes article, IoT integration can lead to a 25% improvement in supply chain traceability and efficiency.

The Role of AI in Predictive Analytics and Optimization of Warehouse Processes

AI plays a crucial role in automating warehouse processes such as slotting optimization, routing, and predictive maintenance. By analyzing large datasets, AI algorithms can identify patterns and insights that may otherwise go unnoticed, leading to more efficient operations and reduced costs. AI also helps mitigate human error, enhancing accuracy and reliability in warehouse tasks.

Moreover, AI assists in predicting demand and inventory levels, enabling better planning and optimization of warehouse space. This can lead to reduced waste and improved customer satisfaction, as products are readily available and delivered on time. With the increasing demand for faster and more efficient warehouse operations, AI is becoming an essential tool for businesses striving to maintain a competitive edge.

A report by Gartner predicts that AI-driven supply chain processes will contribute to a 20% increase in overall warehouse efficiency by 2025.

Improving Order Fulfillment with Voice-Activated Picking Systems

Voice-activated picking systems are gaining popularity in warehouses as they offer an efficient and hands-free method of order fulfillment. Utilizing voice recognition technology, these systems guide workers through the warehouse by providing instructions on where to go and what to pick. This reduces the risk of errors and enhances productivity, leading to faster order fulfillment and increased customer satisfaction.

One of the main advantages of voice-activated picking systems is their seamless integration with existing warehouse management systems. Orders can be automatically sent to the picking system, and workers receive real-time updates on order status. This streamlines the entire order fulfillment process, reducing the time and effort required to manage orders.

Additionally, voice-activated picking systems can be customized to meet the specific needs of a warehouse. For instance, the system can be programmed to recognize different accents or dialects, ensuring effective communication with workers. It can also provide instructions in multiple languages, facilitating the inclusion of non-native speakers in the warehouse workforce.

A study by Ready Robotics found that warehouses implementing voice-activated picking systems experienced a 30% reduction in picking errors and a 20% increase in picking speed.

Benefits of Cloud-Based Warehouse Management Systems for Increased Efficiency

Cloud-based Warehouse Management Systems (WMS) offer numerous benefits for modern warehouses. These systems are scalable, flexible, and accessible from anywhere, making it easier to manage multiple warehouses and locations. Additionally, cloud-based WMS provide real-time data and analytics, enabling businesses to monitor warehouse operations continuously and optimize workflows accordingly.

Another significant advantage of cloud-based WMS is their ability to integrate seamlessly with other systems, such as Transportation Management Systems (TMS) and Enterprise Resource Planning (ERP) systems. This integration helps streamline operations and improve overall supply chain management by ensuring that all systems communicate effectively.

Cloud-based WMS also enhance inventory accuracy and reduce errors. With real-time data and analytics, businesses can accurately track inventory levels and movements, minimizing the risk of stockouts or overstocking. Furthermore, cloud-based WMS can automate inventory management tasks, such as cycle counting and replenishment, reducing the need for manual labor and minimizing errors.

According to a report by Software Advice, companies that adopt cloud-based WMS can achieve up to a 40% improvement in inventory accuracy and a 25% reduction in inventory-related costs.

Smart Warehousing: A Look into Future Trends and Innovations

The future of warehousing is increasingly focused on intelligent and connected systems. Smart warehousing technology aims to make warehouses even more efficient and responsive by leveraging innovations such as Augmented Reality (AR), wearables, and drones. AR can guide workers through the warehouse, reducing the risk of errors and increasing productivity. Wearables provide real-time data and insights to workers and managers, enhancing decision-making and operational efficiency. Drones can be utilized for inventory management, item tracking, and even order fulfillment, further streamlining warehouse operations.

Additionally, advancements in machine learning and AI will continue to drive smart warehousing, enabling more sophisticated predictive analytics and autonomous operations. These technologies will allow warehouses to adapt dynamically to changing conditions, optimize resource allocation, and maintain high levels of efficiency.

Emerging technologies such as blockchain and advanced robotics will also play a crucial role in the evolution of smart warehouses, providing greater transparency, security, and automation in supply chain processes.

Choosing the Right Warehouse Technology for Your Business: Factors to Consider

Selecting the appropriate warehouse technology for your business can be a challenging task. Several factors need to be considered to ensure that the chosen technology aligns with your operational needs and business goals. Key considerations include the size of your warehouse, the complexity of your operations, and your budget constraints.

When evaluating different technologies, it’s essential to assess their impact on productivity, accuracy, and overall efficiency. Additionally, consider the scalability of the technology to accommodate future growth and the ease of integration with existing systems.

Other factors to consider include the level of technical support provided by the technology vendor, the training required for employees to effectively use the new system, and the long-term costs versus the expected benefits. Comprehensive cost-benefit analysis and pilot testing can help in making informed decisions about technology adoption.

A Forbes article suggests that businesses should prioritize technologies that offer flexibility, scalability, and robust support to ensure successful implementation and long-term benefits.

Case Studies: How Companies are Achieving Greater Efficiency through Advanced Warehousing Technologies

Numerous companies have successfully implemented advanced warehousing technologies to achieve greater efficiency and drive growth. For instance, DHL has integrated robotics and IoT technology to optimize workflow and improve accuracy, resulting in a 30% increase in productivity. Similarly, UPS has adopted voice-activated picking systems, leading to a 40% reduction in errors and a 14% increase in productivity.

- DHL: Implemented robotics and IoT for workflow optimization.

- UPS: Adopted voice-activated picking systems to reduce errors.

- Amazon: Utilizes advanced robotics and AI to manage large-scale fulfillment centers efficiently.

- Walmart: Integrated blockchain technology for enhanced supply chain transparency.

These case studies demonstrate the significant impact that advanced warehouse technologies can have on operational efficiency and overall business performance. By leveraging these technologies, companies can streamline their operations, reduce costs, and better meet the evolving demands of the market.

For more detailed insights, refer to the Supply Chain Digital case studies.

Best Practices for Implementing New Warehouse Technologies

Implementing new warehouse technologies can be a complex process, but following best practices can ensure a smooth transition and successful adoption. Key best practices include:

- Evaluate Impact: Assess how the new technology will impact your current operations and identify the specific areas it aims to improve.

- Obtain Stakeholder Buy-In: Engage key stakeholders early in the process to secure their support and address any concerns.

- Invest in Training: Provide comprehensive training for employees to ensure they are proficient in using the new technology.

- Conduct Pilot Testing: Implement the technology on a small scale first to identify potential issues and make necessary adjustments.

- Monitor and Evaluate: Continuously monitor the performance of the new technology and evaluate its effectiveness in achieving desired outcomes.

- Plan for Scalability: Ensure that the technology can scale with your business growth and adapt to changing operational needs.

Additionally, maintaining open communication channels and fostering a culture of continuous improvement can facilitate the successful integration of new technologies.

According to a CIO article, companies that follow structured implementation processes are more likely to achieve higher adoption rates and realize the full benefits of their technology investments.

Overcoming Common Challenges in Adopting New Warehouse Technologies

Adopting new warehouse technologies can present several challenges, including employee resistance, integration issues, and budget constraints. To overcome these obstacles, businesses can adopt the following strategies:

- Engage Employees: Foster a positive attitude towards change by involving employees in the decision-making process and addressing their concerns.

- Provide Comprehensive Training: Equip employees with the necessary skills and knowledge to effectively use the new technology.

- Ensure Seamless Integration: Choose technologies that are compatible with your existing systems and invest in integration support to facilitate smooth implementation.

- Manage Budget Wisely: Plan for the long-term costs and benefits of new technologies, and allocate resources efficiently to support implementation and maintenance.

- Seek Expert Assistance: Collaborate with technology vendors and consultants to navigate complex implementation processes and address technical challenges.

By proactively addressing these challenges, businesses can enhance the likelihood of successful technology adoption and maximize the benefits derived from their investments.

A SHRM article emphasizes the importance of leadership and communication in overcoming resistance to change, highlighting that clear articulation of the benefits and supportive management practices are key to successful technology adoption.

The Future of Warehousing: Forecasting Trends and Predictions

The future of warehousing is poised to be shaped by continued advancements in technology and an increased focus on sustainability and e-commerce. Key trends that are expected to dominate the warehousing landscape include:

- Advanced Robotics and AI: Continued innovation in robotics and AI will further automate warehouse operations, enhancing efficiency and reducing reliance on manual labor.

- IoT Integration: The proliferation of IoT devices will provide even greater visibility and control over warehouse operations, enabling real-time monitoring and optimization.

- Smart Warehousing: Intelligent systems will enable warehouses to become more adaptive and responsive, utilizing technologies like augmented reality and wearable devices to improve productivity.

- Blockchain Technology: Enhanced supply chain transparency and security will be achieved through the adoption of blockchain, reducing fraud and improving traceability.

- Sustainability Initiatives: Warehouses will increasingly adopt sustainable practices, such as energy-efficient lighting, renewable energy sources, and eco-friendly packaging, to minimize their environmental footprint.

- E-commerce Growth: The ongoing expansion of e-commerce will drive demand for more efficient and scalable warehouse solutions to handle increased order volumes.

These trends indicate a future where warehouses are more interconnected, intelligent, and sustainable, enabling businesses to meet the evolving demands of the market with greater agility and efficiency.

A Forbes article projects that the integration of AI and robotics will continue to transform warehouse operations, with smart technologies playing a pivotal role in shaping the next generation of supply chains.