Exploring the Possibilities of Robotics in E-Commerce Logistics

The rise of e-commerce has dramatically transformed the retail landscape, driven by consumers' demand for greater convenience and faster delivery times. To meet these expectations and gain a competitive edge, many businesses are turning to robotics to streamline their logistics processes. This article delves into the potential of robotics in e-commerce logistics, examining their advantages, cost-benefit analysis, and best practices for integration.

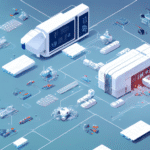

Robotic Solutions and Technologies in E-Commerce Logistics

Automated Material Handling

Robots can automate material handling tasks such as moving products within warehouses, picking and placing items, and operating conveyors and sorters. This automation enhances efficiency and reduces the reliance on manual labor.

Advanced Picking and Packing

With advancements in robotics and artificial intelligence, robots can now perform complex picking and packing operations. These robots can accurately select items, place them in appropriate packaging, and prepare orders for shipment with minimal human intervention.

Inventory Management

Robotic systems can monitor stock levels in real-time, track product locations within warehouses, and manage inventory more effectively. This leads to better inventory accuracy and reduces the chances of stockouts or overstock situations.

Last-Mile Delivery Solutions

Innovations like autonomous delivery vehicles and drones are revolutionizing last-mile delivery. These technologies can significantly reduce delivery times and costs, providing customers with faster and more reliable service.

Benefits of Implementing Robotics in E-Commerce Logistics

Increased Efficiency and Speed

Robots operate 24/7 without the need for breaks, enabling continuous processing and faster order fulfillment. According to a McKinsey report, automation can increase warehouse productivity by up to 25%.

Enhanced Accuracy and Reduced Errors

Robots minimize human errors in order fulfillment, leading to higher accuracy rates. This reduction in errors improves customer satisfaction and decreases the likelihood of returns.

Cost Savings

While the initial investment in robotics can be substantial, the long-term savings from reduced labor costs and increased operational efficiency are significant. Additionally, robotics can optimize warehouse space utilization, lowering storage costs.

Improved Workplace Safety

Automation of repetitive or hazardous tasks reduces the risk of workplace injuries. This not only protects employees but also helps businesses avoid costly workers' compensation claims and enhances overall workplace safety.

Scalability

Robotic systems are highly scalable, allowing businesses to adjust their operations based on demand fluctuations. This flexibility is crucial for handling peak periods, such as holiday seasons, without compromising efficiency.

The Impact of Robotics on Order Fulfillment and Delivery Times

Faster Order Processing

Automated material handling and picking systems enable quicker processing and shipping of orders. A study by Forbes highlights that businesses using robotics can reduce order processing times by up to 30%.

Enhanced Shipping Accuracy

Robots ensure that orders are fulfilled correctly, minimizing the risk of errors. This leads to fewer returns and higher customer satisfaction rates.

Efficient Last-Mile Delivery

Autonomous delivery vehicles and drones can deliver products directly to customers' doors within hours. Companies like Amazon and FedEx are actively testing these technologies to enhance their delivery capabilities.

Workplace Safety and Environmental Impact

By automating physically demanding tasks, robotics reduce workplace injuries. Additionally, optimized delivery routes powered by robotics can decrease fuel consumption, contributing to a lower carbon footprint.

Case Studies of Successful Robotics Implementation in E-Commerce Logistics

Amazon's Robotics Integration

Amazon has heavily invested in robotics through its acquisition of Kiva Systems, now known as Amazon Robotics. These robots navigate warehouses to move products efficiently, significantly enhancing order fulfillment speed and accuracy. According to Amazon, their robotics system has reduced the time it takes to fulfill customer orders by approximately 20%.

FedEx's Autonomous Delivery Solutions

FedEx has integrated robotics into its supply chain and last-mile delivery operations. The company is experimenting with autonomous delivery vehicles and drones to optimize delivery routes and reduce operational costs. This initiative aims to improve delivery times and increase overall efficiency.

Shopify's Robotics Adoption

Shopify has implemented robotic systems in its fulfillment centers to manage high volumes of orders, especially during peak seasons. The automation has enabled Shopify to handle increased demand without compromising on delivery speed or accuracy.

Future Trends and Predictions for Robotics in E-Commerce Logistics

Advancements in Artificial Intelligence

The integration of AI with robotics will lead to more sophisticated automation solutions. AI-powered robots will be able to learn and adapt to changing environments, further enhancing their efficiency and versatility.

Growth of Autonomous Delivery

Autonomous delivery vehicles and drones are expected to become more prevalent, offering faster and more cost-effective delivery options. According to a Business Insider report, the autonomous delivery market is projected to grow significantly in the next five years.

Increased Adoption of Collaborative Robots

Collaborative robots, or cobots, that work alongside human workers will become more common. These robots will handle repetitive and strenuous tasks, allowing human employees to focus on more complex and value-added activities.

Enhanced Data Analytics and Predictive Maintenance

Robotic systems will increasingly incorporate data analytics to predict maintenance needs, optimize performance, and prevent downtime. This proactive approach will ensure that robotic operations remain efficient and reliable.

Overcoming Challenges in Implementing Robotics in E-Commerce Logistics

High Initial Investment

The upfront costs associated with robotics technology can be a significant barrier for many businesses. However, the long-term benefits and cost savings often justify the initial expenditure. Exploring financing options and phased implementation can help mitigate these costs.

Technical Expertise and Training

Implementing and maintaining robotic systems requires specialized technical skills. Businesses may need to invest in training their workforce or partner with robotics providers to ensure successful integration and operation.

Regulatory and Privacy Concerns

Deploying autonomous vehicles and drones involves navigating complex regulatory landscapes and addressing privacy concerns. Businesses must stay informed about relevant regulations and work closely with authorities to ensure compliance.

Integration with Existing Systems

Seamlessly integrating robotics with existing warehouse management and logistics systems is crucial for maximizing efficiency. Investing in compatible technologies and working with experienced integration partners can facilitate a smooth transition.

Cost-Benefit Analysis: Evaluating Robotics Investment for Your E-Commerce Business

Assessing Potential Savings and ROI

A comprehensive cost-benefit analysis helps businesses understand the financial implications of investing in robotics. Key factors include initial investment costs, ongoing maintenance expenses, and potential savings from reduced labor and increased efficiency.

Calculating Efficiency Gains

Robotics can lead to significant efficiency gains, such as faster order processing and higher accuracy rates. Quantifying these improvements can provide a clearer picture of the expected return on investment.

Considering Long-Term Benefits

Beyond immediate cost savings, robotics offer long-term advantages like scalability, enhanced customer satisfaction, and the ability to meet growing demand without proportional increases in labor costs.

Addressing Potential Drawbacks

Potential drawbacks include high initial costs, the need for technical expertise, and possible workforce disruptions. Businesses must weigh these factors against the anticipated benefits to make informed decisions.

Best Practices for Integrating Robotics into E-Commerce Logistics

Strategic Planning and Clear Objectives

Define clear objectives for robotics integration, such as improving order fulfillment speed or reducing labor costs. Strategic planning ensures that the implementation aligns with overall business goals.

Selecting the Right Robotics Solutions

Choose robotic technologies that best fit your operational needs. Consider factors like scalability, compatibility with existing systems, and the specific tasks you aim to automate.

Training and Workforce Development

Invest in training programs to equip your workforce with the necessary skills to work alongside robots. This fosters a collaborative environment and maximizes the benefits of automation.

Partnering with Experienced Providers

Collaborate with reputable robotics providers who can offer expertise, support, and customized solutions. Strong partnerships facilitate smoother implementation and ongoing maintenance.

Continuous Monitoring and Optimization

Regularly monitor the performance of robotic systems and seek opportunities for optimization. Continuous improvement ensures that your automation efforts remain effective and aligned with evolving business needs.

Integrating robotics into your e-commerce logistics strategy requires careful planning and execution. By following best practices and leveraging the benefits of automation, businesses can enhance efficiency, accuracy, and customer satisfaction, ultimately driving profitability and growth.