FedEx Offers Guidelines for Shipping Corrosive Materials

Shipping corrosive materials requires adherence to strict guidelines to ensure safety and compliance. This article explores the importance of following these guidelines, the associated risks, and how FedEx’s protocols mitigate these risks. We will also define corrosive materials, outline proper packaging and labeling techniques, highlight common shipping mistakes, discuss the role of regulatory agencies, and examine the environmental impacts of improper shipping.

Why It's Important to Follow Guidelines for Shipping Corrosive Materials

Shipping corrosive materials without proper guidelines is highly dangerous. Corrosive substances can leak, spill, or even explode during transport, posing risks to handlers, other shipments, and the environment. Non-compliance can result in significant property damage and legal consequences for the shipper.

- Prevents Accidents: Adhering to guidelines minimizes the risk of leaks and spills.

- Ensures Compliance: Following regulations helps avoid legal penalties.

- Protects Material Integrity: Proper packaging prevents reactions that could damage or contaminate the materials.

By following established guidelines, shipments arrive safely and maintain their integrity, ensuring they are in the same condition upon arrival as when shipped.

Understanding the Risks of Shipping Corrosive Materials

Corrosive materials pose severe hazards to both people and the environment. These substances can cause burns to skin, eyes, and respiratory systems, and can corrode or damage other materials and infrastructure. The risks escalate when these materials are not handled or transported correctly.

- Health Hazards: Exposure can lead to serious respiratory, gastrointestinal, and cardiovascular issues.

- Material Damage: Corrosives can degrade containers and other materials, leading to leaks and spills.

- Environmental Pollution: Accidental releases can contaminate soil, water, and air.

Proper labeling, packaging, and training are essential to mitigate these risks and ensure safe transportation.

How FedEx's Guidelines Ensure Safe and Compliant Shipping

FedEx has established comprehensive guidelines for handling and shipping corrosive materials, incorporating training programs, specialized packaging requirements, and meticulous labeling and documentation processes. These guidelines align with standards set by regulatory agencies, ensuring that shipments are both safe and compliant.

- Employee Training: Regular training ensures that staff are knowledgeable about handling corrosives safely.

- Specialized Packaging: Use of containers designed to withstand corrosive substances prevents leaks and spills.

- Proper Labeling: Clear and accurate labels communicate the hazards and handling requirements.

Additionally, FedEx's sustainability initiatives, such as using alternative fuels and eco-friendly packaging, further enhance the safety and environmental responsibility of their shipping operations.

What Corrosive Materials Are and Why They Need Special Handling

Corrosive materials are substances capable of causing damage to other materials they contact. They can exist in solid, liquid, or gaseous forms and are prevalent in industries like manufacturing, healthcare, and agriculture. Due to their reactive nature, corrosive materials require meticulous handling to prevent accidental exposure or environmental release.

- Examples: Strong acids, bases, and oxidizers.

- Hazards: Can cause severe burns, equipment damage, and ecological harm.

- Handling Requirements: Proper identification, containment, and transportation protocols.

Emergency response plans, including the availability of personal protective equipment and spill containment materials, are critical for managing potential accidents.

The Consequences of Improper Shipping of Corrosive Materials

Improper shipping of corrosive materials can result in severe outcomes, including injuries, fatalities, property damage, legal penalties, and environmental pollution. Shippers are responsible for ensuring compliance with safety standards to prevent these adverse consequences.

- Health Risks: Exposure can lead to serious injuries or death.

- Legal Implications: Non-compliance can result in hefty fines and legal action.

- Environmental Damage: Accidental releases can contaminate ecosystems.

Accurate labeling and thorough documentation are crucial to prevent confusion and mishandling during transportation.

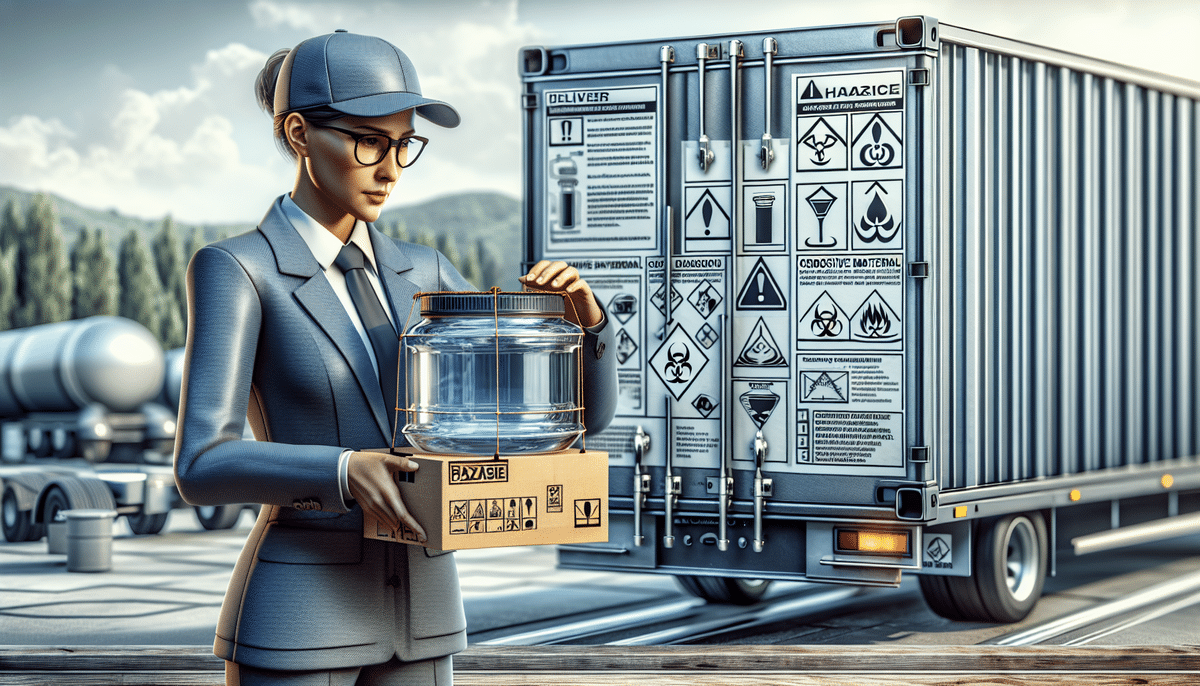

How to Properly Package and Label Corrosive Materials for Shipment

Effective packaging and labeling are vital for the safe shipment of corrosive materials. Packaging must be compatible with the substance to prevent leaks or spills and designed to withstand transportation conditions such as temperature fluctuations and pressure changes.

- Compatible Containers: Use materials like plastic or glass that resist corrosion.

- Secure Packaging: Ensure containers are sealed and secured to prevent movement.

- Clear Labeling: Include the material's name, quantity, hazard class, and shipping information.

All packages should visibly display appropriate warning labels, such as corrosive or hazard symbols, to alert handlers of the potential dangers.

Tips for Choosing the Right Packaging for Your Corrosive Materials

Selecting the appropriate packaging is crucial to ensure the safe and compliant shipment of corrosive materials. Consider the following factors when choosing packaging:

- Material Compatibility: Ensure packaging materials are resistant to the corrosive substance.

- Regulatory Compliance: Packaging must meet all regulatory requirements for hazardous materials.

- Leak-Proof Design: Opt for containers that prevent leakage under various transport conditions.

- Size and Weight: Choose packaging that accommodates the size and weight of the material while adhering to transportation mode restrictions.

Consulting with a packaging supplier or FedEx expert can help in selecting the most suitable packaging for your specific needs.

The Role of Training in Safe Handling and Shipping of Corrosive Materials

Training is pivotal in ensuring the safe and compliant handling and shipping of corrosive materials. Employees must be educated on the hazards, proper handling techniques, packaging requirements, and documentation procedures associated with corrosive substances.

- Hazard Awareness: Understanding the risks and chemical properties of corrosive materials.

- Proper Handling Techniques: Learning how to safely manage and transport corrosive substances.

- Emergency Response: Training on spill containment, cleanup procedures, and injury response.

Regular refresher courses ensure that employees remain updated on the latest safety protocols and regulatory changes.

Regulatory Agencies Overseeing the Handling and Transportation of Corrosive Materials

Several regulatory bodies oversee the handling and transportation of corrosive materials to ensure public safety and environmental protection. Key agencies include:

- United States Department of Transportation (DOT): Through the Pipeline and Hazardous Materials Safety Administration (PHMSA), DOT regulates the transportation of hazardous materials, setting standards for packaging, labeling, and documentation.

- Occupational Safety and Health Administration (OSHA): OSHA establishes workplace safety standards for handling corrosive materials and provides training and educational resources for workers.

- Environmental Protection Agency (EPA): The EPA oversees the environmental impact of hazardous material transportation and sets regulations to prevent pollution.

Compliance with these agencies’ regulations is essential to avoid legal repercussions and ensure the safety of employees and the public.

Common Mistakes to Avoid When Shipping Corrosive Materials

Avoiding common mistakes is critical to ensure the safe shipping of corrosive materials. Common errors include:

- Incompatible Packaging: Using containers that react with corrosive substances.

- Incorrect Labeling: Failing to properly label packages with hazard information.

- Inadequate Documentation: Missing or incomplete shipping papers that detail the hazards and handling instructions.

- Poor Training: Employees lacking proper training on handling and emergency procedures.

- Non-Compliance with Regulations: Ignoring regulatory standards for packaging, labeling, and documentation.

Proper identification of hazards, comprehensive employee training, and thorough emergency response planning are essential to prevent these mistakes and ensure safe shipping practices.

The Environmental Impact of Mishandling or Improperly Shipping Corrosive Materials

Mishandling or improperly shipping corrosive materials can have devastating environmental consequences. These substances can contaminate soil, water sources, and air quality, leading to long-term ecological damage. Wildlife and their habitats are particularly vulnerable to contamination from corrosive spills.

- Soil Contamination: Corrosive spills can degrade soil quality, affecting plant life and agricultural productivity.

- Water Pollution: Contaminants can leach into groundwater and waterways, harming aquatic ecosystems.

- Air Quality: Volatile corrosive substances can release harmful fumes, affecting both human health and the environment.

Implementing stringent shipping guidelines, proper packaging, and effective emergency response plans are essential to mitigate these environmental risks and promote sustainable shipping practices.

Conclusion

Safe and compliant shipment of corrosive materials hinges on proper handling, packaging, labeling, and documentation. Adhering to regulatory standards and providing comprehensive training to employees are paramount in preventing accidents, safeguarding public health, and protecting the environment. By following FedEx’s established guidelines and industry best practices, shippers can ensure the responsible transportation of corrosive materials.