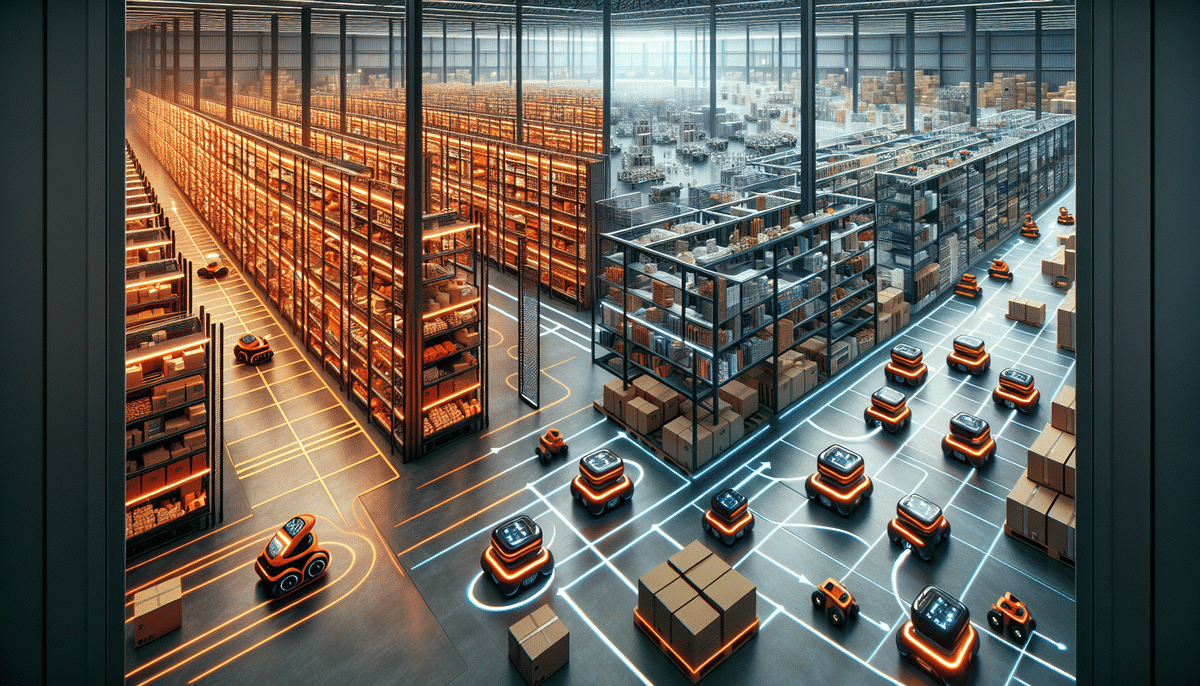

Comparing Warehouse Automation Solutions: Fetch Robotics vs AutoStore

In today's fast-paced business environment, the demand for quick and efficient delivery of goods and services is paramount. Consequently, many companies are investing in warehouse automation solutions to optimize their operations. Two standout companies in this field are Fetch Robotics and AutoStore. This comprehensive comparison will help you determine which system best suits your business needs.

Overview of Fetch Robotics and AutoStore

Fetch Robotics

Fetch Robotics is a California-based company renowned for developing advanced robotics and automation solutions tailored for warehouse and logistics operations. Their flagship product, the Fetch Mobile Robot, is engineered to assist warehouse workers by optimizing processes, thereby enhancing productivity and efficiency. According to a Forbes report, the adoption of mobile robots like Fetch's can increase warehouse efficiency by up to 30%.

AutoStore

AutoStore is a Norwegian company offering a sophisticated warehouse automation system that utilizes a dense grid of bins stacked vertically. These bins are filled with products and managed by robots that efficiently pick and pack items as needed. AutoStore's system is favored by major retailers such as ASOS and Best Buy for its ability to maximize space utilization and handle high volumes of orders. A recent Logistics Management study highlights that AutoStore systems can reduce order processing times by up to 50%.

Technological Foundations

Fetch Robotics Technology

Fetch Robotics employs a blend of sensors, cameras, and mapping technologies to enable their mobile robots to navigate complex warehouse environments seamlessly. The Fetch Mobile Robot is capable of carrying up to 150 lbs of cargo and performing tasks such as transportation, picking, and packing. It integrates effortlessly with existing warehouse management systems, offering a cloud-based platform for remote monitoring and control.

- LiDAR Sensors: Utilize laser scanning to create detailed 3D maps of the environment, ensuring precise navigation.

- Advanced Cameras: Provide real-time visual data to identify and avoid obstacles.

- Mapping Technology: Continuously updates warehouse maps to reflect real-time changes, enhancing adaptability.

According to a McKinsey report, integrating LiDAR and advanced mapping technologies can improve robot navigation accuracy by over 40%.

AutoStore Technology

AutoStore's system is built around a high-density grid of bins that are stacked to maximize vertical space usage. Robots traverse the grid's top, efficiently retrieving and delivering items as required. The system is governed by a central control unit that manages robot movements and task assignments autonomously.

- Grid-Based Architecture: Maximizes space utilization by stacking bins vertically, suitable for high-density storage.

- Autonomous Robots: Efficiently navigate the grid to pick and pack items with high precision and speed.

- Real-Time Data Analytics: Provides actionable insights to optimize warehouse operations continuously.

A study by Supply Chain Digital found that AutoStore systems can handle up to 600 picks per hour, significantly boosting order fulfillment rates.

Performance and Efficiency

Operational Efficiency

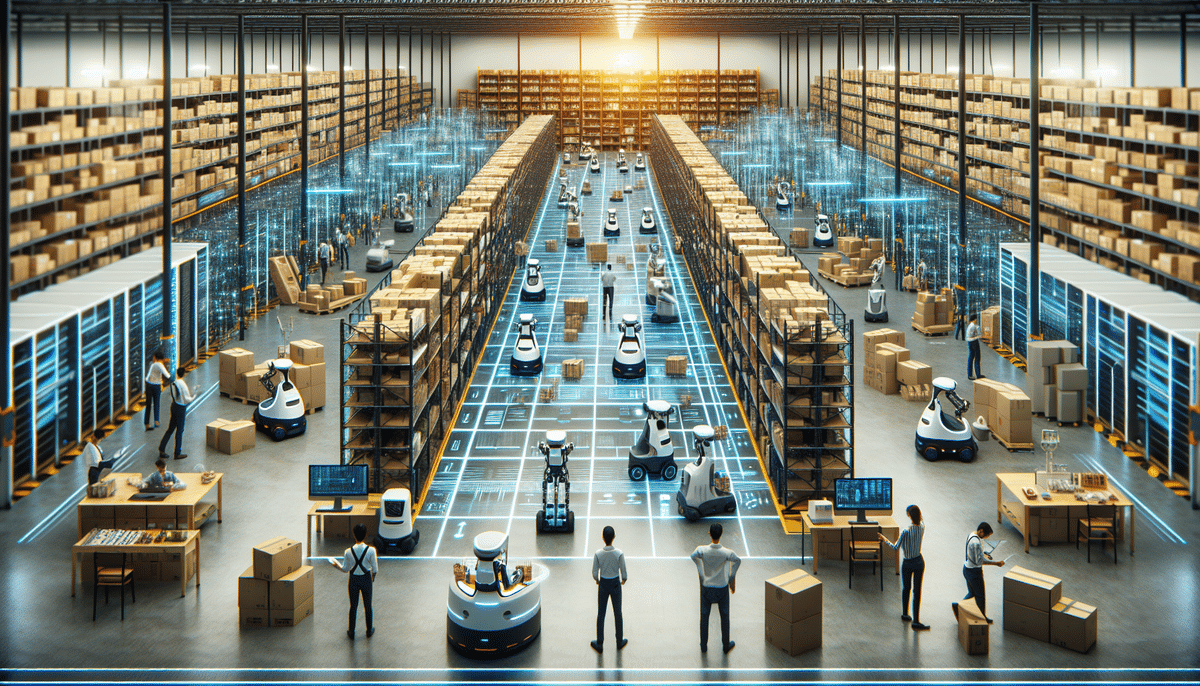

Both Fetch Robotics and AutoStore enhance warehouse efficiency, but they do so in different ways. Fetch Robotics' mobile robots excel in flexible environments, allowing for dynamic task allocation and adaptability to varying warehouse layouts. AutoStore, with its grid-based system, provides unparalleled speed and accuracy in high-density storage scenarios.

According to industry data, companies implementing Fetch Robotics have reported up to a 35% increase in picking efficiency, while those using AutoStore systems have seen productivity surges of up to 50%.

Scalability

Scalability is a critical factor in selecting a warehouse automation solution. AutoStore offers superior scalability for operations dealing with large volumes of goods, as adding more bins and robots can seamlessly expand capacity. Fetch Robotics, while also scalable, relies more on adding additional mobile robots and infrastructure to support larger operations.

In a comparison by Automate.org, AutoStore was highlighted for its ease of scalability in expanding warehouses without significant redesigns.

Cost Analysis

Implementation Costs

Fetch Robotics generally presents a lower initial investment due to its use of off-the-shelf hardware, offering flexibility and quicker deployment. However, costs can escalate with the need for additional robots and maintenance over time. Conversely, AutoStore's system involves higher upfront costs due to custom-designed bins and robots but tends to incur lower maintenance expenses in the long run.

- Fetch Robotics: Lower initial hardware costs, higher flexibility.

- AutoStore: Higher initial investment, optimized for long-term efficiency.

A Business Insider analysis suggests that while Fetch Robotics may offer quicker ROI for smaller operations, AutoStore provides better cost efficiency for enterprises with large-scale automation needs.

Maintenance and Upgrades

Fetch Robotics may require more frequent maintenance and system upgrades due to its reliance on versatile mobile robots operating in diverse environments. AutoStore's fixed grid system is inherently more stable, leading to reduced maintenance requirements and longer equipment lifespans.

Data from Finextra indicates that fixed systems like AutoStore typically incur 20% lower maintenance costs compared to mobile robot systems over a five-year period.

Customer Feedback and Case Studies

Customer Reviews

Customers of Fetch Robotics commend the system for its easy integration and flexibility in performing multiple tasks. AutoStore users praise the system's compact design, high accuracy rates, and ability to manage multiple orders concurrently. However, some feedback points out that Fetch's robots may complete tasks slower than AutoStore's highly optimized system, and AutoStore's design may limit the handling of larger items.

Successful Implementations

Numerous businesses have successfully implemented both systems. For example, DHL Supply Chain enhanced its warehouse operations with Fetch Robotics, resulting in a 35% increase in picking efficiency. Similarly, Norwegian online retailer Komplett saw a 50% boost in productivity after deploying AutoStore solutions.

These case studies, detailed in reports by CIO Review and Retail Dive, underscore the tangible benefits of adopting advanced warehouse automation technologies.

Implementation and Integration

Integration with Existing Systems

Fetch Robotics offers a well-established platform that integrates seamlessly with most warehouse management systems (WMS), facilitating smooth transitions and minimal disruptions during implementation. AutoStore, while more complex to set up, also provides comprehensive support and training to ensure effective integration and operation.

A report by TechRadar emphasizes the importance of robust integration capabilities, which both Fetch Robotics and AutoStore possess, albeit in different operational contexts.

Support and Training

Both companies provide extensive support and training services to assist businesses in adopting their systems. Fetch Robotics focuses on empowering warehouse staff with the skills needed to operate and manage mobile robots, while AutoStore emphasizes training for managing a highly automated grid-based system.

Future Trends in Warehouse Automation

The future of warehouse automation is poised for significant advancements, with companies like Fetch Robotics and AutoStore at the forefront of innovation. Emerging technologies such as artificial intelligence, machine learning, and the Internet of Things (IoT) are expected to further enhance automation capabilities, making systems faster, more efficient, and more adaptable to changing market demands. According to a Gartner forecast, the warehouse automation market is projected to grow by 20% annually over the next five years, driven by these technological advancements.

Selecting the Right Solution for Your Business

Choosing the appropriate warehouse automation solution hinges on your specific business requirements, budget constraints, and long-term operational goals. If your operations demand high-density storage with consistent layouts, AutoStore might be the optimal choice. Conversely, if flexibility and scalability are paramount, Fetch Robotics offers a versatile solution that can adapt to evolving needs.

It's advisable to consult with your operations team and engage with automation solution providers to conduct a thorough needs assessment, ensuring the selected system aligns with your strategic objectives.

Challenges in Implementing Warehouse Automation

While warehouse automation systems offer substantial benefits, several challenges must be addressed during implementation. High initial costs, potential resistance from staff concerned about job displacement, and the complexity of maintaining sophisticated systems are common hurdles. Effective communication about the benefits of automation and comprehensive training programs can mitigate resistance and ensure a smooth transition.

Additionally, integrating new technologies with existing workflows requires careful planning and execution to prevent operational disruptions. Partnering with experienced providers like Fetch Robotics and AutoStore can help navigate these challenges successfully.

Conclusion: Fetch Robotics vs AutoStore

Both Fetch Robotics and AutoStore provide robust and efficient warehouse automation solutions, each with its unique strengths. AutoStore excels in high-density storage and rapid order fulfillment, making it ideal for large-scale operations with consistent inventory. Fetch Robotics offers greater flexibility and scalability, catering to businesses that require adaptable automation solutions. Evaluating your specific business needs, budget, and long-term goals will guide you in selecting the most suitable system. As warehouse automation continues to evolve, both companies remain pivotal in shaping the future of logistics and supply chain management.