Introduction to Fetch Robotics vs Dematic: SEO-Optimized Comparison

In the rapidly evolving landscape of automation and robotics, numerous companies vie to provide cutting-edge technologies that streamline operations, enhance productivity, and reduce costs. Among the top contenders are Fetch Robotics and Dematic. This article offers an in-depth comparison of these two industry leaders, examining their histories, features, market positions, advantages, customer feedback, future prospects, cost structures, integration capabilities, maintenance requirements, and training needs to help businesses determine which solution best fits their needs.

Company Overviews and Histories

Fetch Robotics

Fetch Robotics, established in 2014 by Melonee Wise, Steve Hogan, and Cory Kidd, specializes in autonomous mobile robots (AMRs) designed for material transportation and data collection within warehouses, distribution centers, and manufacturing facilities. The company secured $48 million in funding and formed strategic partnerships with industry giants like Honeywell, Zebra Technologies, and SAP. Fetch Robotics has been recognized for its innovative solutions, earning accolades such as the RBR50 Robotics Innovation Award and the Edison Awards.

Dematic

Dematic, with a heritage dating back to 1819, offers comprehensive intralogistics solutions aimed at optimizing warehouse and factory operations. Originating from MechAir Industries in the UK, Dematic has grown through mergers and acquisitions to solidify its position as a global leader in automated logistics. In 2016, it became part of the KION Group AG, enhancing its global capabilities and market reach. Dematic's portfolio includes automated storage and retrieval systems (ASRS), conveying systems, sorting systems, and robotic picking systems, tailored to enhance efficiency and reduce operational costs.

Key Features and Technologies

Fetch Robotics' Autonomous Mobile Robots

Fetch Robotics' AMRs are celebrated for their flexibility, ease of use, and interoperability. They can be customized for various applications and seamlessly integrate with existing systems. Equipped with advanced sensors, cameras, and software, these robots enable obstacle navigation, object identification, and real-time communication with other systems. In 2020, Fetch Robotics introduced the FetchCore Cloud Robotics Platform, enabling centralized fleet management with real-time performance monitoring and task management capabilities.

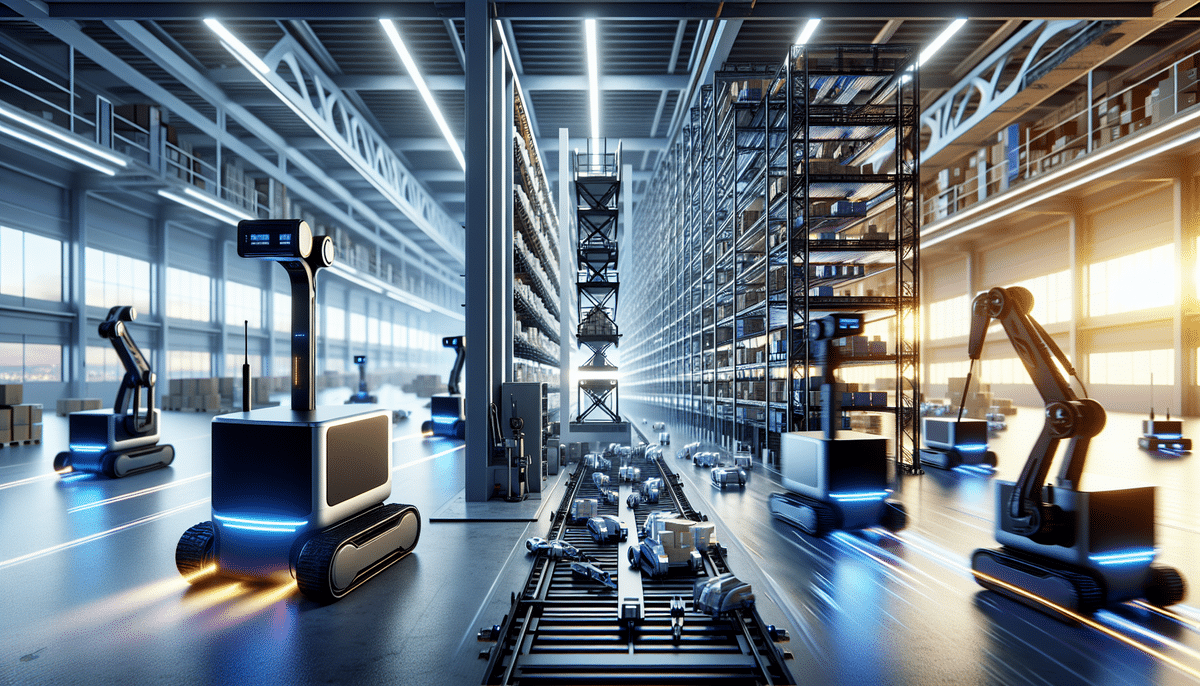

Dematic's Intralogistics Solutions

Dematic's Solutions stand out for their scalability, modularity, and reliability. Their systems are adaptable to diverse material handling needs and can be expanded or upgraded as operational demands evolve. Dematic also offers robust support services, including 24/7 customer assistance, remote monitoring, and predictive maintenance to ensure uninterrupted performance. In 2019, the company established a new research center in the United States to innovate automation solutions for the logistics sector.

Market Position and Future Prospects

As of 2023, both Fetch Robotics and Dematic maintain strong positions in the global automation market. According to a MarketsandMarkets report, the global mobile robotics market is projected to grow from $18.7 billion in 2020 to $54.1 billion by 2026, at a CAGR of 19.6%. This expansion is fueled by increasing automation demands across various industries, positioning both Fetch and Dematic to capture significant market shares through continuous innovation and strategic expansions.

The outlook for both Fetch Robotics and Dematic remains optimistic, driven by the escalating demand for automation and robotics. The surge in e-commerce and the imperative for faster, more efficient order fulfillment position Fetch’s AMRs at the forefront of logistics innovation. Dematic’s extensive experience and versatile solutions enable it to effectively address varied industry needs. Both companies are poised to continue investing in research and development to pioneer new technologies and maintain competitive advantages in the evolving market landscape.

Advantages and Differences Between Fetch Robotics and Dematic

Differences in Technology Focus

Despite their shared goals, Fetch Robotics and Dematic differ in several key areas:

- Technology Focus: Fetch Robotics specializes in mobile AMRs that navigate and interact dynamically within environments, while Dematic focuses on fixed automation systems like conveyors and ASRS.

- Target Markets: Fetch targets sectors such as e-commerce, retail, and logistics, whereas Dematic serves a broader array of industries, including food and beverage, automotive, and healthcare.

- Level of Automation: Fetch’s AMRs offer higher autonomy with minimal human intervention, contrasting with Dematic’s more complex systems that often require greater human oversight.

Advantages of Fetch Robotics

Fetch Robotics' AMRs offer mobility and flexibility, easily adaptable to changing layouts and operational requirements. Their compact size and simple design make deployment cost-effective and less disruptive compared to Dematic’s fixed systems. Additionally, Fetch’s ability to offer remote monitoring and management enhances safety and operational efficiency by reducing the need for on-site personnel.

Advantages of Dematic

Dematic excels in customization and integration, allowing their systems to be tailored precisely to customer specifications and integrated seamlessly with other automation technologies and software. This level of customization ensures optimized operational workflows and maximized ROI. Furthermore, Dematic’s solutions are renowned for their durability and reliability, built to endure heavy-duty usage and maintain high performance over extended periods.

Cost Comparison and Integration Capabilities

Cost Comparison

The investment required for deploying automation solutions from Fetch Robotics or Dematic varies based on factors like facility size, operational complexity, and required technology. Typically, Fetch Robotics’ AMRs are more cost-effective due to their smaller scale and simpler implementation compared to Dematic’s comprehensive systems. However, the overall value depends on specific use cases, with Fetch offering practical solutions for certain applications without compromising on quality or efficiency.

Integration with Other Automation Systems

Both Fetch Robotics and Dematic prioritize compatibility and integration with existing automation technologies and software. Fetch’s AMRs seamlessly integrate with Warehouse Management Systems (WMS), Enterprise Resource Planning (ERP) systems, and various enterprise platforms. Dematic’s solutions are designed to connect with conveyors, robots, and other equipment through diverse control technologies, enabling a cohesive and efficient operational ecosystem that maximizes productivity and minimizes costs.

Maintenance and Training Requirements

Maintenance Requirements

The maintenance demands for Fetch Robotics and Dematic solutions differ due to their inherent designs:

- Fetch Robotics: AMRs are relatively low-maintenance, requiring periodic battery replacements, software updates, and minimal supervision. Their self-contained nature ensures that most maintenance tasks can be managed remotely.

- Dematic: Fixed automation systems necessitate more intensive maintenance routines, including regular inspections, cleaning, lubrication, and component replacements to maintain optimal performance and prevent downtime.

Training Requirements

The training needs for implementing Fetch Robotics or Dematic solutions are contingent on system complexity:

- Fetch Robotics: AMRs offer intuitive interfaces that require minimal training for basic operations. However, advanced functionalities and customizations may necessitate specialized training sessions.

- Dematic: Given the complexity of Dematic’s systems, comprehensive training programs are essential for operators and maintenance teams. Training typically includes classroom instruction, hands-on practice, and certification to ensure proficient system management.

Customer Reviews and Feedback

Feedback for both Fetch Robotics and Dematic is predominantly positive. Clients commend Fetch Robotics for the ease of use, flexibility, and adaptability of their AMRs, alongside excellent customer support and responsiveness. Dematic users highlight the reliability, scalability, and customization of their solutions, appreciating the company's expertise in delivering complex, tailored automation systems that enhance operational efficiency and profitability.

Notable customers for Fetch Robotics include DHL, GE, and Walmart. Dematic serves a broader spectrum, with notable customers like Coca-Cola, Amazon, and BMW.

Industries Served by Fetch Robotics and Dematic

Both Fetch Robotics and Dematic cater to a diverse range of industries. Fetch’s AMRs are prevalent in warehouses, fulfillment centers, and light assembly lines, enabling efficient material handling and data collection. In contrast, Dematic serves a broader array of industries, including food and beverage, automotive, and healthcare, providing comprehensive intralogistics solutions tailored to each sector's unique needs.

Conclusion: Which is Better - Fetch Robotics or Dematic?

Determining whether Fetch Robotics or Dematic is superior depends on specific business requirements and operational contexts. Fetch Robotics excels in providing mobile, flexible, and easily deployable AMRs ideal for dynamic and space-constrained environments. In contrast, Dematic offers scalable, reliable, and highly customizable automation systems suited for a broader range of industries and complex operational needs.

Ultimately, the choice between Fetch Robotics and Dematic should be guided by factors such as the nature of operations, scalability needs, budget constraints, and the desired level of automation. Both companies offer robust solutions that can significantly enhance efficiency and productivity when aligned with the right business strategies.