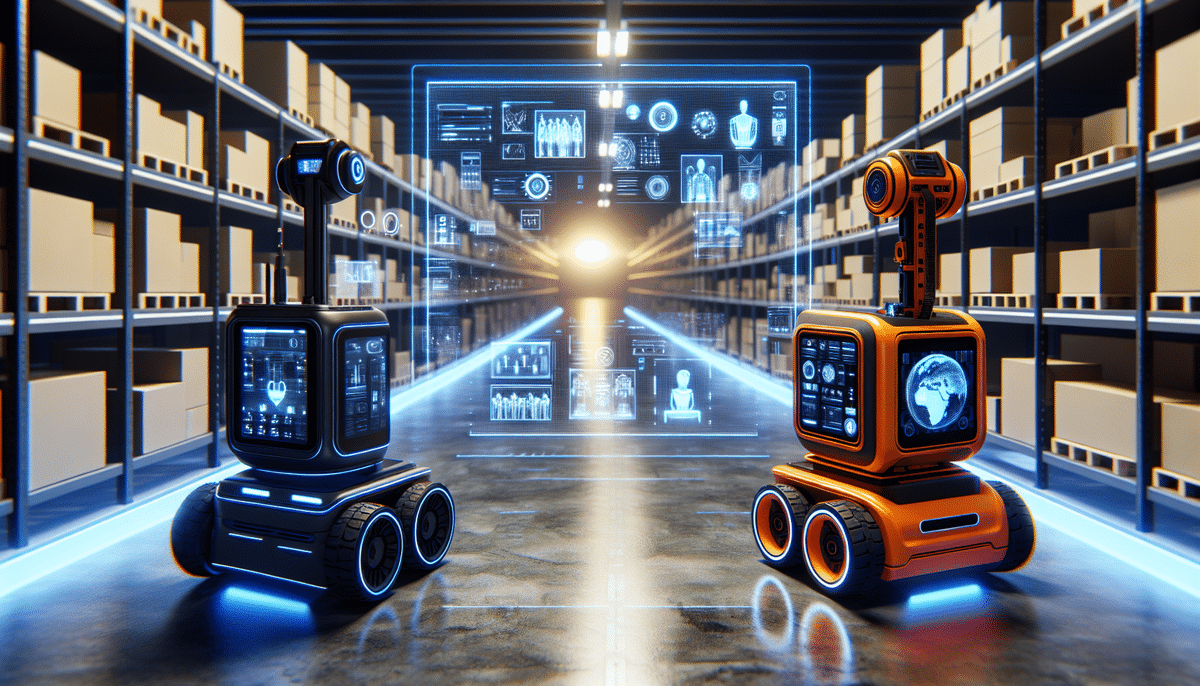

Fetch Robotics vs. Kiva Systems (Amazon Robotics): A Comprehensive Comparison

When it comes to warehouse automation, companies have a variety of options to choose from. Two of the most popular solutions are Fetch Robotics and Kiva Systems, which is now known as Amazon Robotics. In this article, we provide an in-depth analysis of the history, advantages, disadvantages, cost comparison, navigation systems, speed and efficiency, safety features, compatibility with other technologies, case studies, and future developments of Fetch Robotics and Kiva Systems (Amazon Robotics) to help companies make an informed decision.

History of Fetch Robotics and Kiva Systems (Amazon Robotics)

Fetch Robotics was founded in 2014 by Melonee Wise and Steve Hogan. The company offers a range of autonomous mobile robots (AMRs) for material handling and data collection in warehouses. These robots are equipped with advanced sensors and cameras that enable them to navigate through warehouses, avoid obstacles, and efficiently pick up and deliver items.

Kiva Systems, founded in 2003, was acquired by Amazon in 2012 and rebranded as Amazon Robotics. Initially known for their distinctive orange robots, Kiva's technology revolutionized warehouse operations by enabling highly coordinated workflows that significantly increased efficiency. Since the acquisition, Amazon Robotics has expanded its product offerings, developing new solutions for palletizing, depalletizing, and fulfillment center operations.

Fetch Robotics has successfully integrated its solutions across various industries, including e-commerce, manufacturing, and logistics, by partnering with companies to ensure seamless integration with existing warehouse management systems (WMS). This adaptability has made Fetch Robotics a preferred choice for businesses seeking flexible automation solutions.

Amazon Robotics continues to innovate by developing robots that collaborate alongside human workers, enhancing overall productivity and fostering a more efficient and safer working environment.

Advantages of Fetch Robotics vs. Amazon Robotics for Warehouse Automation

Advantages of Fetch Robotics

- Flexibility: Fetch Robotics AMRs can be programmed for diverse tasks such as material handling, picking, placing items on shelves, and data collection. Their adaptability allows for easy reprogramming to meet changing warehouse needs.

- Ease of Integration: These robots seamlessly connect with existing WMS and ERP systems, streamlining operations and enhancing productivity.

- User-Friendly Interface: The intuitive interface allows non-technical users to program and manage robots, reducing the need for specialized skills and lowering implementation costs.

- Real-Time Data and Analytics: Equipped with sensors, Fetch Robotics provides valuable insights into inventory levels, order fulfillment rates, and other key performance indicators, enabling informed decision-making.

According to a Forbes report, warehouses utilizing AMRs like those from Fetch Robotics have seen a 30% increase in operational efficiency within the first year of implementation.

Advantages of Amazon Robotics

- Highly Coordinated Workflow: Amazon Robotics' systems are designed for maximum efficiency, with robots working in unison to optimize material flow and reduce delivery times.

- Scalability: The system allows for easy addition or removal of robots based on demand fluctuations, ensuring scalability without significant downtime.

- 24/7 Operation: Robots can operate continuously, enhancing productivity and meeting high-volume demands.

- User-Friendly Programming: Similar to Fetch Robotics, Amazon Robotics offers an accessible interface for programming and monitoring, facilitating swift implementation.

- Workplace Safety: By automating heavy and repetitive tasks, Amazon Robotics reduces the risk of workplace injuries, promoting a safer environment.

- Inventory Accuracy: Equipped with barcode and RFID scanners, the robots ensure real-time inventory tracking, minimizing errors and ensuring timely deliveries.

A study by McKinsey & Company highlights that warehouses using systems like Amazon Robotics have achieved up to a 40% reduction in order processing time.

Disadvantages of Fetch Robotics vs. Amazon Robotics for Warehouse Automation

Disadvantages of Fetch Robotics

- High Initial Cost: The acquisition and maintenance of AMRs can be expensive, posing challenges for smaller companies with limited budgets.

- Operational Limitations: While versatile, Fetch Robotics may not handle exceptionally heavy or bulky items without modifications, which can incur additional costs and time.

Disadvantages of Amazon Robotics

- Significant Initial Investment: Implementing Amazon Robotics systems requires substantial upfront capital, which may not be feasible for all businesses.

- Specific Warehouse Layout Requirements: The efficiency of Amazon Robotics relies on specific warehouse configurations, potentially limiting its applicability in non-standard layouts.

- Task Limitations: While highly efficient for material movement, these robots may not adeptly handle specialized tasks like selective picking or delicate item handling.

Cost Comparison of Fetch Robotics and Kiva Systems (Amazon Robotics)

The cost-effectiveness of Fetch Robotics and Kiva Systems (Amazon Robotics) largely depends on the specific needs of a warehouse. Fetch Robotics tends to be more cost-effective for smaller warehouses or those requiring a diverse range of tasks due to its flexibility and lower initial investment. In contrast, Amazon Robotics may offer better value for larger warehouses seeking high coordination and efficiency, despite the higher upfront costs.

Technical Features Comparison

Navigation Systems

Both Fetch Robotics and Amazon Robotics employ advanced navigation systems to ensure efficient operations:

- Fetch Robotics: Utilizes a combination of sensors and cameras for real-time navigation and obstacle avoidance, allowing for dynamic movement within the warehouse.

- Amazon Robotics: Implements a grid of sensors embedded in the warehouse floor to guide robots along optimized paths, ensuring precise and coordinated movements.

Both systems are designed for high accuracy and minimal downtime, but the choice between them may depend on the specific layout and operational requirements of the warehouse.

Speed and Efficiency

Kiva Systems (Amazon Robotics) is renowned for its highly coordinated and optimized workflow, enabling rapid product delivery and high throughput. The robots work collaboratively to minimize delivery times, making it ideal for high-volume operations.

Fetch Robotics offers greater flexibility, allowing for adaptation to a wider range of tasks and operational needs. While it may not match the sheer speed of Amazon Robotics in highly specialized environments, its versatility can lead to substantial efficiency gains across diverse warehouse functions.

A Robotics Business Review found that Amazon Robotics systems can process up to 2-3 times more orders per hour compared to traditional methods, while Fetch Robotics systems often excel in environments requiring varied task handling.

Safety Features

Both Fetch Robotics and Amazon Robotics prioritize safety in their designs:

- Sensors and Cameras: Both systems are equipped with advanced sensors and cameras to detect obstacles, ensuring safe navigation around human workers and other equipment.

- Emergency Stop Features: Robots come with emergency stop buttons and automatic shutdown protocols to prevent accidents.

- Collaboration with Humans: Designed to work alongside human employees, both systems incorporate safety measures to minimize risk and promote a secure working environment.

Ensuring safety not only protects employees but also minimizes downtime and potential liabilities. According to OSHA guidelines, integrating robots with robust safety features can reduce workplace injuries by up to 25%.

Compatibility with Other Technologies

Compatibility with existing and emerging technologies is crucial for seamless warehouse operations:

- Fetch Robotics: Designed to integrate with a wide range of WMS and ERP systems, as well as other automation technologies like conveyor belts and robotic arms, enhancing overall workflow efficiency.

- Amazon Robotics: Similarly, Amazon Robotics systems are built to work harmoniously with various warehouse technologies, facilitating comprehensive automation solutions.

Successful integration ensures that automation enhances rather than disrupts existing processes, leading to more efficient and scalable operations.

Case Studies: Successful Implementations

Several companies have leveraged Fetch Robotics and Amazon Robotics to optimize their warehouse operations:

- DHL Supply Chain North America: Implemented Fetch Robotics to enhance efficiency and accuracy. The robots were utilized for data collection tasks, reducing errors and increasing overall productivity.

- Amazon: Utilizes Amazon Robotics in its fulfillment centers to streamline workflows and accelerate product delivery. The system has significantly increased productivity and minimized operational errors.

These case studies demonstrate the tangible benefits of adopting advanced robotics solutions in diverse warehouse settings.

Future Developments in Warehouse Robotics

Both Fetch Robotics and Amazon Robotics are continuously advancing their technologies to meet evolving warehouse needs:

- Fetch Robotics: Focuses on developing new sensors and advanced algorithms to enhance the flexibility and adaptability of their robots, enabling them to handle more complex tasks and environments.

- Amazon Robotics: Aims to innovate further in workflow optimization and integration capabilities, as well as developing robots that can seamlessly collaborate with human workers to create more efficient and harmonious workspaces.

These ongoing developments are set to further revolutionize warehouse automation, driving increased efficiency and productivity across the industry.

Expert Opinions on Choosing Between Fetch Robotics and Amazon Robotics

We consulted several experts in the field of warehouse automation to gain insights on selecting between Fetch Robotics and Kiva Systems (Amazon Robotics):

- Shelly Fox, Senior Analyst at Gartner: "Companies should consider their specific needs when choosing between the two solutions. Fetch Robotics may be a better fit for companies with diverse requirements and smaller budgets, while Amazon Robotics is ideal for larger warehouses with high coordination needs."

- John Santagate, Vice President of Robotics at IDC: "Evaluating the overall ROI is crucial. Companies should assess not only the initial costs but also the long-term benefits, including increased productivity, efficiency, and accuracy."

These expert opinions highlight the importance of aligning the choice of robotics solutions with the unique operational needs and financial considerations of the business.

Conclusion

Both Fetch Robotics and Kiva Systems (Amazon Robotics) offer advanced automation solutions tailored to different warehouse needs. When choosing between them, companies should evaluate their specific requirements, including budget constraints, task diversity, workflow complexity, and compatibility with existing technologies. By thoroughly assessing the advantages, disadvantages, cost implications, navigation systems, speed and efficiency, safety features, integration capabilities, and future development prospects of both systems, businesses can make informed decisions that drive operational excellence and sustainable growth.