Fetch Robotics vs Knapp: A Comprehensive SEO-Optimized Comparison

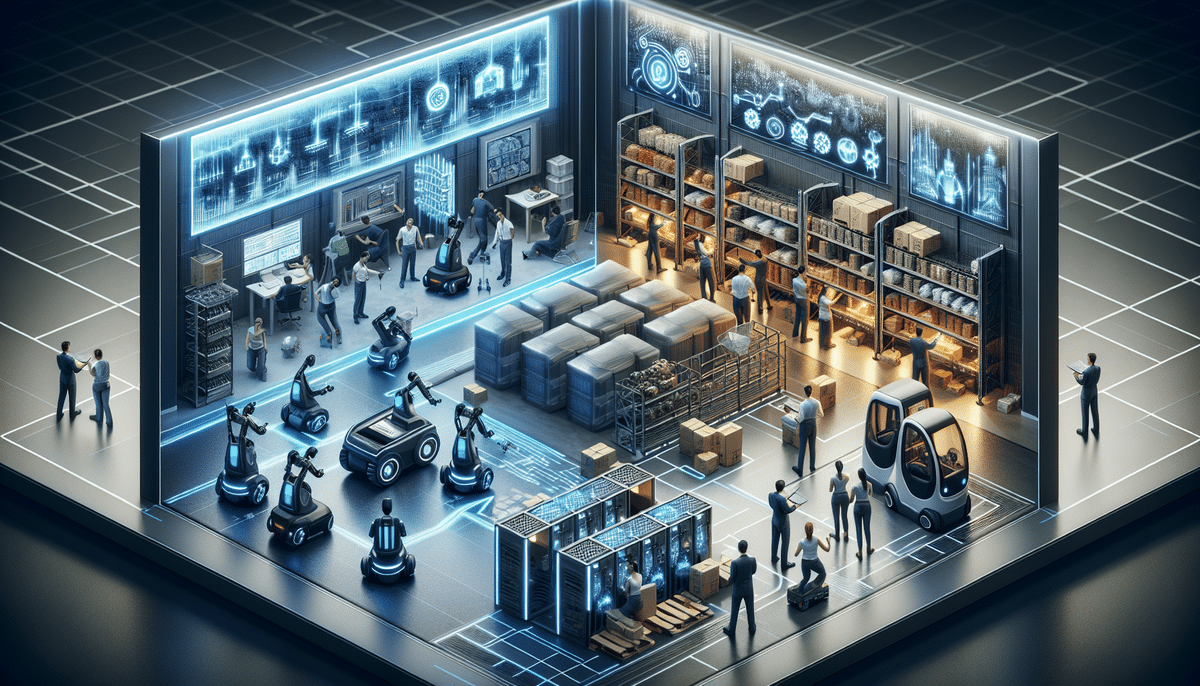

In the realm of automated warehouses, Fetch Robotics and Knapp stand out as industry leaders. Both companies provide innovative solutions to enhance warehouse efficiency, but determining the best fit depends on specific operational needs. This article delves into the similarities, differences, and unique features of Fetch Robotics and Knapp to guide your decision-making process.

Overview of Fetch Robotics and Knapp

Understanding the core offerings of each company is essential before making a comparison:

- Fetch Robotics: Established in 2014, Fetch Robotics specializes in autonomous mobile robots (AMRs) designed for tasks such as material transport, order fulfillment, and data collection. Their robots collaborate seamlessly with human workers, enhancing productivity and safety.

- Knapp: With over six decades of experience, Knapp offers a broad spectrum of warehouse automation solutions, including automated storage and retrieval systems (AS/RS), shuttle systems, and conveyor systems. They also provide comprehensive warehouse management and control software.

While Fetch Robotics focuses on the development and deployment of AMRs, Knapp provides a more extensive range of automation solutions tailored to optimize entire warehouse operations.

Comparative Analysis: Fetch Robotics vs Knapp

Technology and Innovation

- Fetch Robotics: Utilizes LiDAR technology for precise navigation and obstacle avoidance. Their software incorporates machine learning algorithms to optimize robot routes, enhancing efficiency over time.

- Knapp: Implements advanced automation technologies, including robotics, automated guided vehicles (AGVs), and high-speed conveyor systems. Their solutions are designed for scalability and integration with existing warehouse infrastructures.

Solution Focus

- Fetch Robotics: Emphasizes collaborative robots that work alongside human workers, ideal for environments where flexibility and human-robot interaction are crucial.

- Knapp: Focuses on fully automated systems that reduce the need for human intervention, suitable for high-volume warehouses seeking maximum efficiency.

Customization and Flexibility

- Fetch Robotics: Offers customizable solutions tailored to specific client needs, allowing for scalability and adaptability as operational demands evolve.

- Knapp: Provides comprehensive automation solutions with a focus on optimizing overall warehouse operations, often requiring a more significant upfront investment.

Pricing Models

- Fetch Robotics: Adopts a subscription-based pricing model, providing flexibility and scalability without large upfront costs.

- Knapp: Utilizes a traditional pricing model with equipment purchases, which can be more cost-effective for long-term, high-volume operations.

Customer Support and Service

- Fetch Robotics: Known for responsive and agile customer support, offering dedicated teams for installation, maintenance, and troubleshooting.

- Knapp: Offers expert customer support with comprehensive training and documentation, ensuring effective operation of their complex automation systems.

Key Similarities and Differences

Similarities

- Both provide customizable automation solutions tailored to individual warehouse needs.

- Each offers software solutions for the control and management of their automation systems.

Differences

- Technology Focus: Fetch Robotics centers on AMRs, while Knapp offers a diverse range of automation systems including AS/RS and conveyor systems.

- Operational Approach: Fetch Robotics promotes human-robot collaboration, whereas Knapp emphasizes full automation to streamline warehouse processes.

- Company Experience: Fetch Robotics is a newer player with a modern technological approach, whereas Knapp brings over 60 years of industry expertise.

Case Studies: Success Stories

Real-world applications highlight the effectiveness of each company's solutions:

- Fetch Robotics: DHL Supply Chain integrated Fetch Robotics' AMRs to enhance warehouse efficiency, resulting in a 40% reduction in order processing errors.

- Knapp: Swisslog implemented Knapp's shuttle systems, increasing pallet storage capacity by 150% and streamlining inventory management.

Industry Reputation and Future Outlook

Fetch Robotics has rapidly established itself as an innovator in the AMR space, receiving accolades such as Gartner's Cool Vendor in Robotics in 2018. Strategic partnerships with industry leaders like SAP and Ricoh bolster their credibility and market presence.

Knapp, with its long-standing history, is revered for reliable and scalable warehouse automation solutions. Their extensive portfolio and industry experience make them a trusted partner for large-scale operations.

The future of warehouse automation is poised for growth, with both Fetch Robotics and Knapp expected to integrate emerging technologies such as artificial intelligence (AI), the Internet of Things (IoT), and advanced data analytics to further enhance warehouse efficiency and adaptability.

Pros and Cons

Fetch Robotics

Pros:

- Collaborative robots designed to work alongside humans.

- Highly customizable and scalable solutions.

- Modern and innovative technology with user-friendly interfaces.

Cons:

- Relatively new company with less industry experience compared to established players.

Knapp

Pros:

- Over 60 years of industry experience and a strong reputation.

- Reliable and proven automation solutions.

- Wide range of products catering to various warehouse needs.

Cons:

- More traditional approach may lack the flexibility of newer technologies.

- Less emphasis on collaborative robots compared to Fetch Robotics.

Choosing the Right Solution for Your Warehouse

When deciding between Fetch Robotics and Knapp, consider the following factors:

- Warehouse Size and Complexity: Larger, more complex warehouses may benefit from Knapp's comprehensive automation systems, while smaller or dynamic environments might find Fetch Robotics' AMRs more suitable.

- Budget: Evaluate whether a subscription-based model (Fetch Robotics) or an outright purchase (Knapp) aligns better with your financial strategy.

- Operational Needs: Determine if you require collaborative robots that work alongside humans or fully automated systems that handle high volumes efficiently.

- Technical Expertise: Assess the level of technical expertise within your team to operate and maintain the chosen system effectively.

Consulting with industry experts or reaching out to both companies for detailed proposals can also aid in making an informed decision.

Conclusion: Fetch Robotics or Knapp?

Both Fetch Robotics and Knapp offer robust, state-of-the-art warehouse automation solutions. The optimal choice hinges on your specific operational requirements, budget constraints, and long-term strategic goals. By thoroughly evaluating the features, benefits, and potential drawbacks of each company, you can select the solution that best enhances your warehouse's efficiency and productivity.