Geek+ vs Knapp: A Comprehensive Comparison of Warehouse Automation Leaders

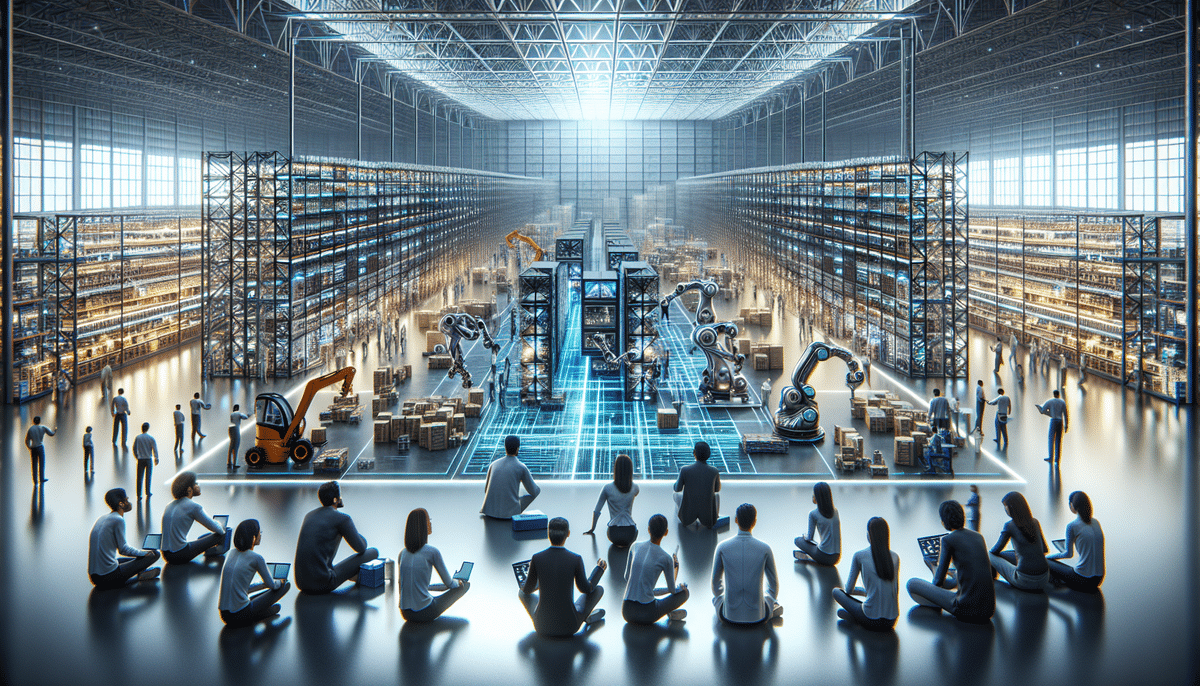

Warehouse automation is essential for streamlining operations and enhancing productivity in today’s fast-paced logistics environment. Among the top providers of automation solutions are Geek+ and Knapp. This article offers an in-depth analysis of Geek+ and Knapp, examining their histories, advantages and disadvantages, technological capabilities, future prospects, case studies, implementation strategies, maintenance and support, cost structures, scalability and customization options, key features, and ease of use to help businesses make informed decisions.

Overview of Geek+ and Knapp

Geek+ and Knapp are two leading players in the warehouse automation industry, offering a range of solutions that include warehouse management software, autonomous mobile robots (AMRs), and other advanced technologies. Their primary objective is to reduce dependency on manual labor, minimize human error, and maximize operational efficiency.

With the exponential growth of e-commerce, the demand for efficient warehouse operations has surged. Geek+ and Knapp provide automation solutions that enable warehouses to manage increased order volumes with greater accuracy and speed, thereby enhancing the overall customer experience. Additionally, both companies offer customizable solutions tailored to the specific needs of various warehouse sizes and configurations, making them versatile options for businesses of all scales.

Comparative Analysis of Geek+ and Knapp

History and Market Presence

Geek+ was founded in 2015 in China with the mission to revolutionize the logistics industry through cutting-edge warehouse robotics. Despite its relatively recent inception, Geek+ has rapidly gained recognition for its innovative solutions. In 2018, Geek+ was awarded the "Robotics Company of the Year" at the Supply Chain Asia Awards, highlighting its position as a leader in warehouse robotics.

Knapp, an Austrian company, boasts over 60 years of experience in the warehouse automation sector. Specializing in automated storage and retrieval systems (AS/RS), intralogistics solutions, and software development, Knapp has established itself as a trusted name worldwide, with solutions deployed across various industries.

Advantages and Disadvantages

Geek+

- Advantages:

- Flexible robot deployment

- Cost-effective solutions

- High productivity and scalability

- Customizable to various warehouse sizes and layouts

- Disadvantages:

- Relatively limited market experience compared to established players

- Potential challenges in global support infrastructure

Knapp

- Advantages:

- Proven and reliable solutions with decades of market presence

- High efficiency, accuracy, and speed in operations

- Comprehensive range of technologies including shuttle systems and conveyors

- Disadvantages:

- Higher cost may be prohibitive for smaller companies

- Less flexibility in customization compared to newer competitors

Both Geek+ and Knapp offer unique strengths and face distinct challenges. Geek+ excels in flexibility and innovation, making it suitable for businesses seeking adaptable solutions. Conversely, Knapp's extensive experience and reliable systems make it an attractive option for companies prioritizing proven technology.

Technological Capabilities

Geek+

- Focuses on human-robot collaboration, enhancing flexibility in operations.

- Seamless integration with third-party systems, allowing for versatile customization.

- Utilizes lithium-ion batteries in robots, promoting sustainability and longer lifespan.

- Incorporates AI-driven algorithms for optimized task allocation and route planning.

Knapp

- Offers a diverse array of technologies, including shuttle systems, conveyors, and automated storage.

- Emphasizes speed and precision, ideal for high-volume warehouse environments.

- Incorporates regenerative braking technology in shuttle systems to reduce energy consumption.

- Advanced software solutions for real-time data analytics and inventory management.

Both companies prioritize sustainability, with Geek+ adopting environmentally friendly battery technology and Knapp implementing energy recovery systems. This commitment not only reduces operational costs but also aligns with global sustainability goals.

Cost Structure

- Geek+:

- Typically charges per robot, making it a scalable option for various budget sizes.

- Generally lower initial investment compared to Knapp, making it more accessible for smaller to mid-sized businesses.

- Knapp:

- Higher pricing due to the sophistication and comprehensiveness of their systems.

- May require a larger upfront investment, which can be justified by the long-term reliability and efficiency gains.

It's advisable to request detailed quotes from both companies and conduct a cost-benefit analysis based on your specific operational needs and budget constraints.

Scalability and Customization

- Geek+:

- Highly scalable, allowing businesses to expand their automation systems as needed.

- Offers extensive customization options to tailor solutions to specific operational requirements.

- Knapp:

- Provides scalable systems suitable for both small-scale operations and large, high-volume warehouses.

- Customization options are available, particularly for integrating advanced technologies like shuttle systems.

Scalability and customization are crucial for adapting to changing business needs and ensuring long-term efficiency and growth.

Maintenance and Support

- Geek+:

- Offers 24/7 technical support to address any operational issues promptly.

- Features a global network of service centers, ensuring comprehensive coverage for multinational operations.

- Provides regular software updates and maintenance services as part of their support package.

- Knapp:

- Delivers comprehensive support and maintenance services, ensuring system reliability and longevity.

- While their global service network is robust, it may be more limited in certain regions compared to Geek+.

- Includes software updates and preventive maintenance as part of their service offerings.

Choosing a provider with strong support and maintenance services is essential to minimize downtime and ensure continuous operational efficiency.

Key Features

Geek+

- Flexible deployment options for robots and automation systems.

- Easy scalability to accommodate growth and increased demand.

- Seamless integration with existing warehouse management systems and third-party technologies.

- Advanced robotics with human-robot collaboration capabilities.

- AI-driven analytics for optimized operations.

Knapp

- High-volume capacity systems suitable for large-scale operations.

- Superior speed and precision in order fulfillment and inventory management.

- Automated storage and retrieval systems (AS/RS) for efficient space utilization.

- Regenerative braking technology in shuttle systems to enhance energy efficiency.

- Comprehensive data analytics and real-time monitoring tools.

These key features enable both Geek+ and Knapp to deliver tailored solutions that meet the diverse needs of modern warehouses.

Ease of Use

- Geek+:

- Known for its intuitive installation and setup processes.

- User-friendly interfaces that simplify operation and management.

- Scalable systems that grow with your business needs without requiring extensive reconfiguration.

- Knapp:

- Systems may have a steeper learning curve due to their complexity and advanced features.

- Comprehensive training and support are provided to ensure users can effectively manage and operate the systems.

- Once mastered, Knapp's systems offer robust performance and reliability.

Overall, Geek+ tends to be more accessible for users seeking straightforward implementation and ease of use, while Knapp offers powerful features that, although initially complex, provide substantial benefits once fully integrated into operations.

Case Studies: Success Stories with Geek+ and Knapp

Numerous companies have successfully implemented Geek+ and Knapp systems, demonstrating significant improvements in efficiency and productivity:

Novio Logistics

Novio, a leading logistics provider in Switzerland, integrated a Geek+ Robotics system, resulting in a 40% increase in order processing capacity. This enhancement allowed Novio to meet growing customer demands without compromising on accuracy or speed.

Asda

Asda, a major UK supermarket chain, deployed Knapp's warehouse automation solutions, leading to a 25% improvement in warehouse efficiency. The implementation of shuttle systems and conveyors enabled faster order fulfillment and reduced operational bottlenecks.

DHL

DHL, a global logistics giant, utilized a combination of Geek+ and Knapp's systems across their warehouses. This hybrid approach led to a 30% boost in productivity and a 50% reduction in error rates, showcasing the complementary strengths of both technologies.

These case studies highlight the tangible benefits of adopting advanced warehouse automation systems, including increased capacity, enhanced efficiency, and improved accuracy.

Implementation Strategies

Implementing Geek+ or Knapp requires careful planning and execution to ensure a smooth transition and optimal performance:

- Assessment of Warehouse Needs: Evaluate your current operations, identify pain points, and determine the specific automation solutions that will address your unique challenges.

- System Selection: Choose the right system based on your needs, whether it's the flexibility of Geek+ or the proven reliability of Knapp.

- Installation and Testing: Collaborate with experienced providers to install the system and conduct thorough testing to ensure all components function correctly.

- Training: Provide comprehensive training for your staff to effectively operate and manage the new automation systems.

- Ongoing Support: Establish a support framework with your provider to address any issues and maintain system performance.

Effective communication with your team is essential to prepare them for new workflows and processes introduced by the automation system.

The Future of Warehouse Automation

As leaders in warehouse automation, Geek+ and Knapp are at the forefront of driving future innovations in the industry:

- Human-Robot Collaboration: Enhanced collaboration between human workers and robots to improve efficiency and safety.

- Integration with IoT: Leveraging the Internet of Things (IoT) for smarter inventory management and real-time data analytics.

- Machine Learning and AI: Utilizing advanced algorithms to optimize warehouse operations, predict maintenance needs, and enhance decision-making processes.

According to a McKinsey report, the adoption of AI and machine learning in warehouse automation is expected to grow by 40% over the next five years, highlighting the industry's shift towards more intelligent and autonomous systems.

However, the rise of automation also brings challenges, particularly concerning workforce impacts. Companies must invest in retraining programs to equip employees with the skills needed to manage and collaborate with advanced automated systems.

Conclusion

Geek+ and Knapp are both leading warehouse automation systems that offer unique advantages tailored to different business needs. Geek+ excels in flexibility, scalability, and innovative human-robot collaboration, making it ideal for businesses seeking adaptable and cost-effective solutions. In contrast, Knapp stands out with its proven reliability, high efficiency, and advanced technological features, making it suitable for large-scale, high-volume warehouse operations.

Choosing the right system requires a thorough assessment of your business requirements, budget, and long-term operational goals. By leveraging the strengths of Geek+ or Knapp, companies can significantly enhance their warehouse efficiency, reduce operational costs, and improve overall productivity.

As warehouse automation technologies continue to evolve, both Geek+ and Knapp are well-positioned to drive the future of logistics and supply chain management, ensuring that businesses remain competitive in an ever-changing market landscape.

For more information on implementing warehouse automation solutions, visit the official websites of Geek+ and Knapp.