GreyOrange vs Dematic

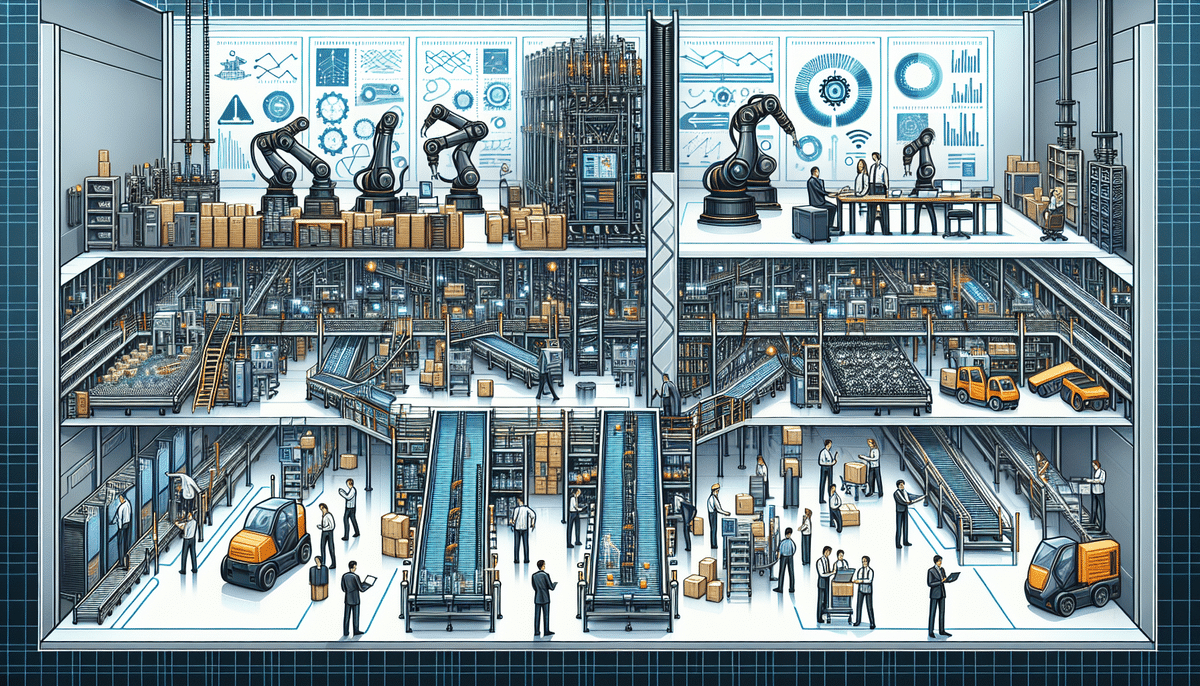

When it comes to industrial automation and material handling solutions, two names that are commonly mentioned are GreyOrange and Dematic. Both companies offer a range of solutions to help businesses improve their operations, but how do they compare? In this article, we provide a comprehensive comparison of GreyOrange vs Dematic to help you make an informed decision for your business needs.

Understanding GreyOrange and Dematic

GreyOrange is an Indian multinational robotics company specializing in end-to-end automation solutions for supply chain and logistics operations. Their solutions incorporate artificial intelligence, machine learning, and robotics to optimize workflow and improve efficiency.

Dematic, a global leader in industrial automation, offers a comprehensive range of material handling solutions, order fulfillment systems, and warehouse automation technologies. They serve a diverse clientele across industries, from e-commerce to automotive manufacturing.

GreyOrange has been recognized as a leader in robotics and automation, winning several awards for their innovative solutions. They have partnered with major companies such as Flipkart, the largest e-commerce company in India, to implement their automation technology.

Dematic boasts a strong presence in North America, Europe, and Asia-Pacific, with over 10,000 employees worldwide. They have a proven track record of delivering successful automation projects, helping clients improve operational efficiency and reduce costs.

Industrial Automation: An Overview

Industrial automation involves using technology to perform tasks that were previously done manually. Automation can help businesses improve efficiency, accuracy, and productivity while reducing labor costs. Material handling is a crucial aspect of industrial automation, involving the movement, storage, and control of goods.

One of the key benefits of industrial automation is the ability to collect and analyze data. Automation systems can gather data on production rates, equipment performance, and other important metrics. This data can then be used to identify areas for improvement and optimize processes. Additionally, automation can help reduce errors and improve safety by removing the need for human intervention in hazardous or repetitive tasks.

According to a report by McKinsey & Company, automation can increase productivity by up to 30% while reducing operational costs by 20-25%.

Market Share Comparison

According to industry reports, Dematic is currently the market leader in the material handling automation market, holding a share of over 20%. GreyOrange, though a relatively new player, has gained significant attention and is rapidly increasing its market share through innovative solutions.

GreyOrange's success can be attributed to their focus on developing AI-powered solutions that optimize warehouse operations. Their flagship product, the Butler system, uses advanced algorithms to efficiently manage inventory and reduce order processing time, leading to increased productivity and cost savings for clients.

Conversely, Dematic has been in the market for over 200 years and has a strong reputation for providing reliable and scalable solutions. They offer a wide range of products and services, including automated storage and retrieval systems, conveyor systems, and sortation systems. Their extensive experience and expertise have cemented their position as the market leader.

Key Features of GreyOrange and Dematic Solutions

Both GreyOrange and Dematic offer a variety of solutions to automate material handling operations:

- GreyOrange: Automated storage and retrieval systems, sortation systems, goods-to-person systems, and robotic picking systems.

- Dematic: Conveyor systems, automated storage and retrieval systems, order fulfillment systems, and automated guided vehicles.

GreyOrange's solutions are renowned for their AI-powered optimization capabilities, helping businesses enhance warehouse efficiency and reduce operational costs. Dematic's solutions, designed to be scalable and flexible, allow businesses to adapt to changing market demands and customer needs. Both companies have a strong track record of delivering innovative and reliable solutions, making them top choices for automating material handling operations.

Which Offers Better Material Handling Solutions?

Choosing between GreyOrange and Dematic depends on several factors, including the specific needs of your business, budget, and workflow complexity. GreyOrange is known for its AI-powered robotics and strong focus on optimizing warehouse operations, while Dematic offers a broader range of solutions with a reputation for effectiveness across various industries.

While GreyOrange may have a more specialized focus, Dematic's extensive range of solutions provides greater flexibility in addressing specific needs. Dematic also has a strong track record of successful implementations and high customer satisfaction. Ultimately, the decision will hinge on your business's unique requirements and the specific challenges you aim to address.

Case Studies: Success Stories

Several businesses have benefited from the automation solutions provided by GreyOrange and Dematic:

- KerryIndev, a leading logistics provider in India, increased its capacity by 2.5 times and reduced turnaround time by 50% after implementing GreyOrange's robotic solutions.

- Toyota Australia enhanced efficiency and productivity by 25% following the installation of Dematic's automated storage and retrieval system.

- Flipkart, India's largest e-commerce company, implemented GreyOrange's automated sortation system, processing 4,500 shipments per hour with a 99.5% accuracy rate. This led to a 60% reduction in processing time and a 50% reduction in operational costs.

- DHL Supply Chain increased productivity by 200% by deploying Dematic's automated guided vehicles (AGVs) in their warehouse, significantly reducing labor costs and enhancing efficiency.

These case studies highlight the significant impact that advanced automation solutions can have on operational efficiency and cost reduction.

Pros and Cons of GreyOrange and Dematic Systems

When selecting an automation system, it's essential to consider the pros and cons of each option:

- GreyOrange:

- Pros:

- High accuracy

- Advanced robotics

- Real-time data analytics

- Cons:

- Relatively new in the market

- Limited global presence compared to Dematic

- Pros:

- Dematic:

- Pros:

- Reliable and well-established

- Broad range of solutions

- Global support network

- Cons:

- Higher costs

- May require significant customization

- Pros:

Another factor to consider is the level of support and maintenance offered. GreyOrange, with a smaller customer base, can provide more personalized support and faster response times. In contrast, Dematic has a larger team of experienced technicians and engineers, benefiting complex installations and ongoing maintenance needs.

Pricing Comparison

The cost of automation systems varies based on size, complexity, and customization:

- GreyOrange: Solutions range from $50,000 to $5 million.

- Dematic: Solutions range from $100,000 to $10 million or more.

It's essential to obtain a customized quote from each provider tailored to your specific business needs. Remember that the initial cost isn't the only factor; consider customer support, maintenance services, and the provider's industry reputation. Additionally, some providers may offer financing or leasing options to help manage upfront costs. Thorough research and comparison are recommended before making a decision.

After-Sales Support

After-sales support is crucial for the successful implementation and maintenance of automation systems:

- GreyOrange:

- 24/7 support

- On-site maintenance

- Remote monitoring

- Personalized training for employees, conducted on-site and remotely

- Dematic:

- Extensive customer support

- Equipment maintenance and spare parts

- Software upgrades

- Comprehensive online knowledge base with user manuals and troubleshooting guides

Both companies offer robust customer support, but GreyOrange provides more personalized training, while Dematic offers extensive online resources for self-help.

Future Trends in Industrial Automation

Both GreyOrange and Dematic continue to innovate to meet evolving business needs:

- GreyOrange: Expanding solutions to include robotic picking for fresh produce and investing in autonomous mobile robots (AMRs) for material handling.

- Dematic: Developing solutions to optimize warehouse design and layout, and investing in cloud-based software for real-time data and insights.

Expect advancements in robotics, AI, and data analytics to further improve material handling operations. Both companies are at the forefront of industrial automation innovation, positioning themselves to meet the growing demand for faster and more efficient solutions.

Final Verdict: Choosing Between GreyOrange and Dematic

Both GreyOrange and Dematic offer innovative automation solutions for material handling. The choice depends on various factors, including:

- Budget

- Business needs

- Workflow complexity

GreyOrange is renowned for its advanced robotics solutions and focus on optimizing operations, while Dematic offers a wider range of solutions with a well-established reputation across industries.

It's essential to consult with experts and obtain customized quotes from both providers. Additionally, consider the level of customer support and service offered, including technical support, training, and ongoing maintenance, to ensure smooth long-term operations.

Reading reviews and case studies from other customers can also provide valuable insights into their experiences working with each company, helping you make a well-informed decision.