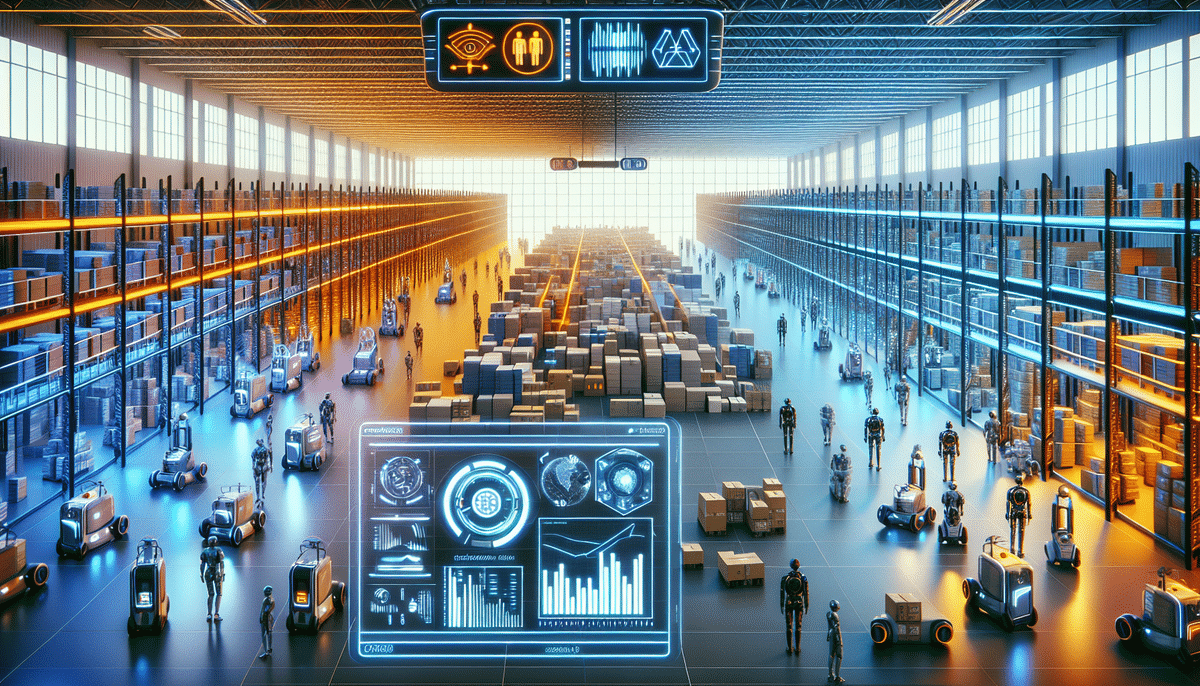

Introduction to Warehouse Robotics

Robotics has become a cornerstone in modern warehousing and logistics, driving significant improvements in efficiency, accuracy, and scalability. According to a Statista report, the global warehouse robotics market is projected to grow exponentially, fueled by the surge in e-commerce and the need for rapid order fulfillment. This article delves into a comprehensive comparison of two industry leaders in warehouse automation: GreyOrange and Fetch Robotics.

GreyOrange: Innovations and Solutions

Founded in 2011 in Singapore, GreyOrange has established itself as a global leader in AI-powered robotics solutions for warehousing and logistics. With a presence in over 20 countries, GreyOrange offers a robust portfolio of products and services designed to optimize warehouse operations:

- Butler System: An autonomous mobile robot engineered for efficient goods transportation within warehouses, boasting a payload capacity of up to 1,600 pounds per trip.

- Linear Sorter: A high-speed automated sorting system capable of processing up to 14,400 parcels per hour, significantly enhancing order fulfillment speed and accuracy.

- Warehouse Automation Software: Comprehensive software solutions that provide real-time visibility, process optimization, and seamless integration with existing warehouse management systems.

GreyOrange's solutions are implemented by major clients such as Flipkart, Jabong, and Kerry Logistics, who have reported substantial improvements in operational efficiency and cost reductions.

Fetch Robotics: Enhancing Warehouse Efficiency

Fetch Robotics, headquartered in San Jose, California, specializes in mobile robotics and advanced software solutions tailored for warehouses and factories. Since its inception in 2014, Fetch Robotics has developed a range of innovative products aimed at optimizing inventory management and order fulfillment:

- Fetch Robot: An autonomous mobile robot designed for inventory management and picking tasks, with a payload capacity of up to 100 pounds.

- Freight Robot: A robust mobile platform built for transporting heavy items, supporting payloads of up to 2,200 pounds per trip.

- FetchCore: A versatile software platform that allows users to manage and monitor their robot fleets, customize workflows, and integrate with third-party systems.

Fetch Robotics' solutions are utilized by companies like RK Logistics Group and MonarchFx, enabling them to achieve higher accuracy and faster order processing times.

Comparative Analysis: GreyOrange vs. Fetch Robotics

Operational Scale and Flexibility

GreyOrange offers scalable solutions suitable for a wide range of warehouse environments, from small facilities to large distribution centers. Their Butler System and Linear Sorter can be expanded to accommodate growing operational demands. In contrast, Fetch Robotics emphasizes flexibility with a diverse range of robots tailored to various tasks, allowing businesses to customize their robotic fleet based on specific needs.

Product Range and Capabilities

While GreyOrange primarily focuses on goods transportation and high-speed sorting, Fetch Robotics provides a broader spectrum of products, including inventory management and heavy item transportation. This diversity allows Fetch Robotics to cater to a wider array of operational requirements.

Software Integration and Management

GreyOrange's proprietary Warehouse Management System (WMS) seamlessly integrates with existing systems, providing real-time data on inventory and order fulfillment. On the other hand, Fetch Robotics' FetchCore offers extensive customization and third-party integrations, enabling businesses to tailor the platform to their specific workflows and operational strategies.

Customer Support and Global Reach

GreyOrange boasts a substantial global presence, offering localized support and services across multiple regions. Fetch Robotics, while also globally recognized, places a strong emphasis on customer satisfaction with responsive support services and high customer ratings.

Feature Comparison: Navigational Technologies and Performance

- Navigation: GreyOrange utilizes a patented SLAM (Simultaneous Localization and Mapping) algorithm for precise real-time mapping and navigation. Fetch Robotics employs advanced sensors and adaptable navigation systems, allowing their robots to operate effectively in diverse environments.

- Payload Capacity: GreyOrange's Butler System can handle up to 1,600 pounds, making it suitable for transporting heavy goods. Conversely, Fetch Robotics' Fetch Robot is designed for lighter tasks, carrying up to 100 pounds, while the Freight Robot supports up to 2,200 pounds.

- Battery Life: GreyOrange’s Butler System offers up to 12 hours of operation on a single charge, whereas Fetch Robotics' Fetch Robot provides approximately 8 hours, depending on usage patterns and operational conditions.

- Scalability and Customization: GreyOrange’s modular approach allows businesses to scale their robotic fleets as needed. Fetch Robotics offers a variety of robot types, enabling greater customization based on specific operational requirements.

Performance Metrics: Speed, Accuracy, and Efficiency

- Speed and Sorting Capacity: GreyOrange's Linear Sorter can handle up to 20,000 parcels per hour, delivering exceptional speed and efficiency in sorting operations. Fetch Robotics' Fetch Robot is optimized for versatile tasks, including inventory management and item retrieval, emphasizing operational flexibility over sheer speed.

- Automation Level: GreyOrange provides fully autonomous operations with minimal human intervention, ensuring continuous and reliable performance. In contrast, Fetch Robotics offers a blend of autonomy and human control, allowing for remote management and oversight when necessary.

Cost Analysis: Evaluating Value and ROI

When assessing the cost-effectiveness of these solutions, it's essential to consider both initial investment and long-term return on investment (ROI):

- GreyOrange: Typically involves higher upfront costs due to advanced features and scalability, making it ideal for larger operations seeking comprehensive automation and significant ROI through enhanced efficiency.

- Fetch Robotics: Offers more cost-effective solutions for smaller operations or businesses that prioritize flexibility and lower initial investments, enabling quicker deployment and shorter payback periods.

Real-World Implementations: Case Studies

- GreyOrange: DTDC, a leading Indian logistics company, integrated GreyOrange’s Butler System, resulting in a 30% increase in warehouse throughput and a 25% reduction in operational costs. Kerry Logistics in Hong Kong also leveraged GreyOrange solutions to streamline their sorting operations, achieving higher accuracy and faster processing times.

- Fetch Robotics: RK Logistics Group in California implemented Fetch Robotics’ Fetch Robots to optimize their inventory management, leading to a 20% improvement in picking accuracy and a 15% increase in order fulfillment speed. MonarchFx in Georgia utilized the Freight Robot to enhance their heavy item transportation, significantly reducing labor costs and improving operational efficiency.

Future Outlook: Advancements in Warehouse Robotics

The future of warehouse robotics is set to be shaped by continuous advancements in artificial intelligence, machine learning, and automation technologies. Both GreyOrange and Fetch Robotics are at the forefront of this evolution, investing in research and development to create more intelligent and capable robots. Emerging trends include the integration of collaborative robots (cobots) that work alongside human workers, enhanced data analytics for predictive maintenance, and the adoption of autonomous systems that require minimal human oversight. These innovations are expected to further revolutionize warehouse operations, driving greater productivity and operational efficiency.

Conclusion: Choosing the Right Robotics Solution for Your Business

Selecting the appropriate robotics solution requires a thorough evaluation of your business’s specific needs, operational goals, and budget. GreyOrange and Fetch Robotics both offer robust and innovative solutions tailored to different aspects of warehouse automation. GreyOrange excels in large-scale, fully autonomous operations with extensive sorting capabilities, making it suitable for enterprises seeking comprehensive automation. Fetch Robotics provides flexible and customizable solutions with a diverse product range, ideal for businesses looking for adaptable and cost-effective robotic systems. By carefully assessing factors such as features, scalability, performance, and cost, businesses can make informed decisions to adopt the robotics solution that best aligns with their operational objectives and drives long-term success.