Introduction to GreyOrange and Knapp Robotics

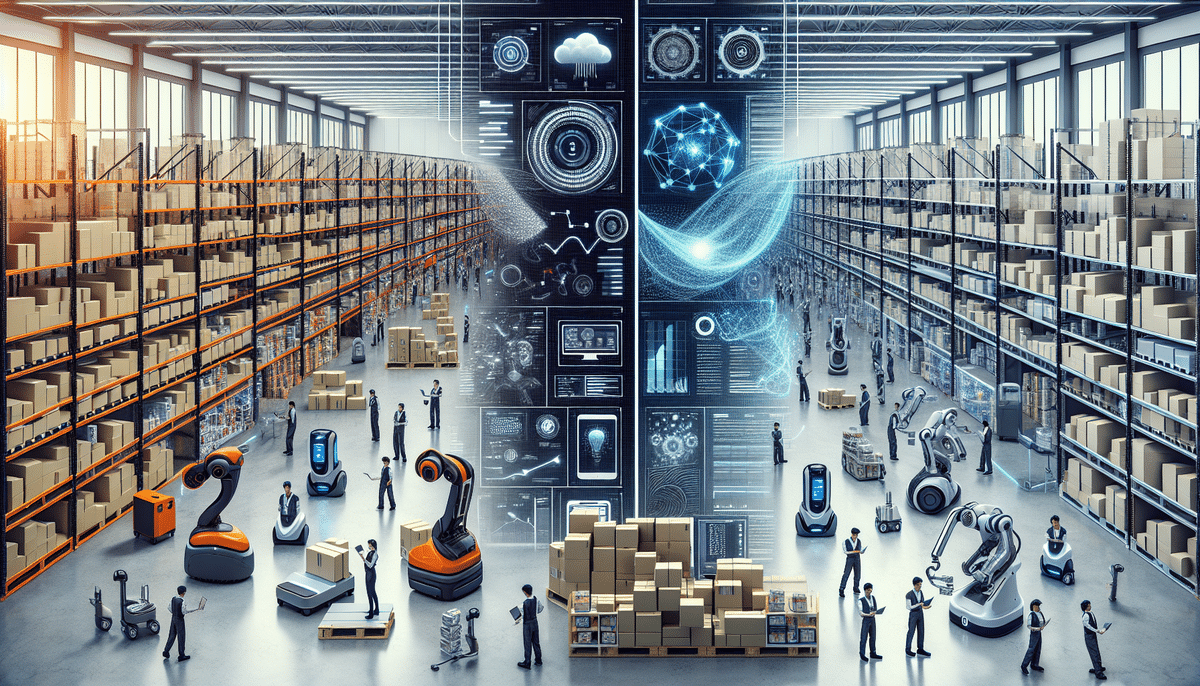

The warehousing industry has been transformed by advancements in robotics, enabling businesses to optimize operations and enhance efficiency. Implementing sophisticated automated solutions offers a significant competitive advantage in today's market. Among the leading innovators in this space are GreyOrange and Knapp Robotics. This article provides a comprehensive comparison of these two industry leaders, examining their technologies, features, benefits, and suitability to help you make an informed decision.

Company Overview

GreyOrange

Founded in 2011 in Singapore by Samay Kohli and Akash Gupta, GreyOrange initially focused on developing robotic solutions for mail sorting. The company quickly pivoted towards warehousing automation, securing over $200 million in funding and expanding its global footprint. GreyOrange leverages artificial intelligence and machine learning to create adaptable solutions capable of handling diverse scenarios, making it a key player in the rapidly evolving robotics industry.

Knapp Robotics

Knapp Robotics, with roots dating back to 1952 in Austria, has a long-standing history in conveyor technology before expanding into comprehensive automation solutions. Today, Knapp Robotics employs over 5,000 professionals and serves a wide range of industries, including healthcare, retail, and pharmaceuticals. Known for its innovative and reliable automation solutions, Knapp Robotics continues to drive advancements in warehouse automation with over five decades of industry experience.

Technology and Features

GreyOrange Technology

The GreyOrange system integrates both hardware and software to deliver a seamless automation experience. It features autonomous robots that navigate warehouses, retrieve items, and transport them efficiently. Powered by advanced software that maps and controls robot movements, GreyOrange adapts to varying warehouse layouts and operational demands, optimizing workflows in real-time.

Knapp Robotics Technology

Knapp Robotics employs a modular approach to automation. Its autonomous robots manage item transport across warehouses, guided by sophisticated software that oversees their movements. The system's modularity allows for scalable integration, making it easier for businesses to expand their automation capabilities as demands grow.

Key Features Comparison

- GreyOrange:

- Real-time data optimization for seamless operational adjustments

- High adaptability to diverse warehouse configurations

- Advanced algorithms enabling autonomous decision-making

- Knapp Robotics:

- Modular design for easy scalability and integration

- Advanced safety sensors to prevent collisions and ensure workplace safety

- User-friendly interface with comprehensive analytics tools

Pros and Cons

GreyOrange

- Pros:

- Highly adaptable and customizable solutions

- Advanced AI and machine learning capabilities

- Low maintenance requirements with autonomous operations

- Cons:

- Initial investment may be significant for some businesses

- Requires specialized staff for optimal operation and maintenance

Knapp Robotics

- Pros:

- Modular design facilitates easy scalability

- Robust and reliable automation systems

- Enhanced safety features ensure operational safety

- Cons:

- Integration into existing setups can be complex

- Higher initial costs for implementing modular systems

Customer Reviews and Feedback

Feedback for both GreyOrange and Knapp Robotics has been largely positive, with customers highlighting several strengths:

- Workflow Optimization: Both systems enhance efficiency and streamline operations, leading to faster order fulfillment.

- Ease of Use: Users appreciate the intuitive interfaces and user-friendly systems of both solutions.

- Scalability: The ability to expand automation systems in line with business growth is a significant advantage for both GreyOrange and Knapp Robotics.

Some customers have noted that the initial setup process can be time-consuming. However, the long-term benefits in terms of operational efficiency and cost savings often outweigh the initial investment. Additionally, the support provided by both companies has been praised for ensuring smooth implementation and ongoing operations.

Implementation and Pricing

Implementation Steps

- Assess Your Needs: Evaluate your current warehouse operations to identify areas that would benefit most from automation.

- Choose the Right System: Based on your needs assessment, decide whether GreyOrange’s adaptable solutions or Knapp Robotics’ modular systems are more suitable.

- Partner with Experts: Work with certified partners or directly with the companies to design and plan the implementation process.

- Train Your Team: Provide comprehensive training for your staff to ensure they can operate and maintain the new systems effectively.

- Implement Incrementally: Start with a pilot project to test the system’s effectiveness before a full-scale rollout.

- Monitor and Optimize: Continuously monitor the system’s performance and make necessary adjustments to optimize operations.

Price Comparison

The cost of implementing GreyOrange versus Knapp Robotics varies based on factors such as warehouse size, operational complexity, and customization requirements:

- GreyOrange:

- Offers more affordable solutions for SMEs

- Pricing based on scalability and customization options

- Provides flexible financing and leasing options

- Knapp Robotics:

- Higher initial investment suited for large enterprises

- Costs vary based on modular system configurations

- Includes comprehensive support and maintenance packages

Both systems offer significant cost savings over time through improved efficiency and reduced labor costs. It is advisable to consult with financial advisors or directly with the companies to obtain a detailed cost analysis tailored to your specific needs.

Future Developments

Both GreyOrange and Knapp Robotics are committed to continuous innovation to keep their solutions at the forefront of warehouse automation:

- GreyOrange: Developing the Butler PickPal, a system designed to enhance item picking accuracy and speed. Additionally, GreyOrange is investing in expanding its AI capabilities to further optimize warehouse operations.

- Knapp Robotics: Enhancing software intelligence by developing more adaptive algorithms that allow robots to better respond to dynamic warehouse environments. Knapp is also exploring collaborative robotics to work more effectively alongside human workers.

These advancements aim to provide even more efficient, intelligent, and user-friendly automation solutions, addressing the evolving needs of the warehousing industry.

Conclusion

In conclusion, both GreyOrange and Knapp Robotics offer exceptional solutions for automating warehousing operations. GreyOrange excels in adaptability and customization, making it ideal for SMEs seeking flexible automation. On the other hand, Knapp Robotics, with its modular and scalable systems, is well-suited for large enterprises requiring robust and comprehensive automation solutions.

When choosing between the two, consider factors such as business size, operational complexity, customization needs, budget, and the level of technical support required. By carefully evaluating these aspects and leveraging the strengths of each system, you can implement a robotics solution that best aligns with your business goals and enhances your warehouse efficiency.