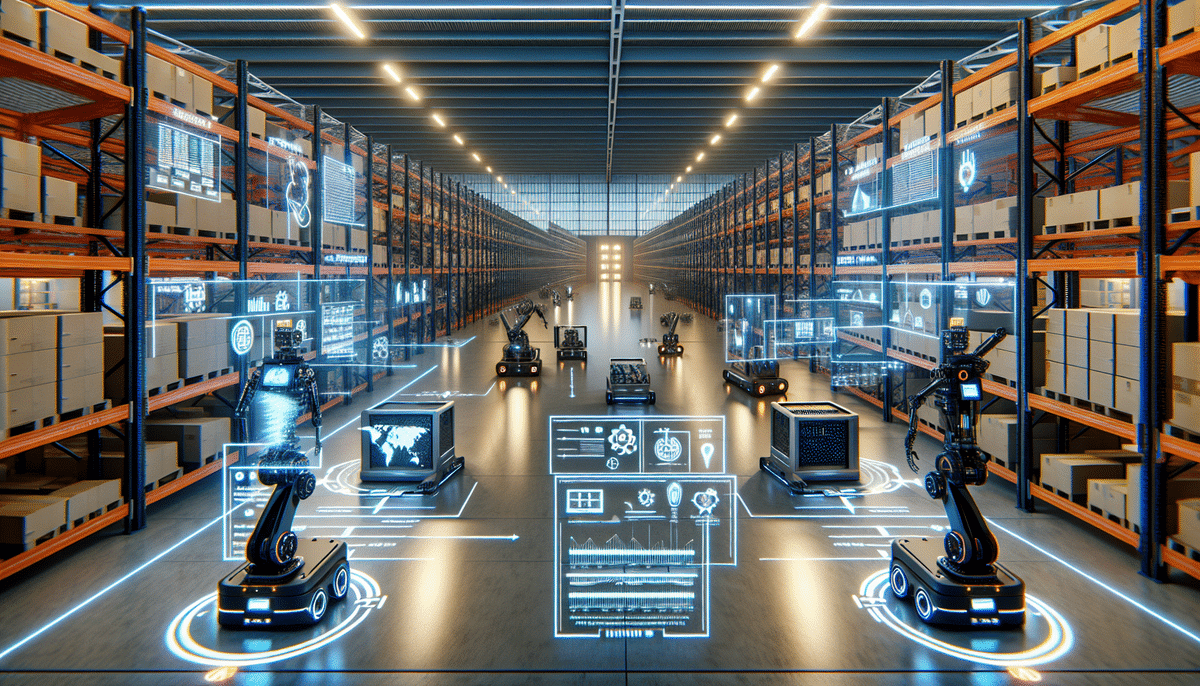

Introduction to Automated Warehousing and Material Handling Systems

Automated warehouses and material handling systems have fundamentally transformed how businesses manage inventory and move products. By integrating cutting-edge technology, these systems optimize warehouse operations, enhance supply chain efficiency, and drive significant cost savings. According to a McKinsey report, automation can increase productivity by up to 25% while reducing operational costs by 20%. This comprehensive analysis compares two leading companies in this space: GreyOrange and Swisslog, examining their features, functionalities, pricing, and real-world applications to help businesses make informed decisions.

Company Overviews

GreyOrange: Background and History

Founded in 2011, GreyOrange is a pioneering robotics and automation company headquartered in Singapore, with additional offices in India, Japan, and the United States. The company offers a suite of solutions, including the Butler robotics system, designed to collaborate with human workers for efficient product transportation within warehouses. Their software solutions focus on inventory optimization and overall warehouse automation.

Expanding beyond warehouse automation, GreyOrange has developed the GreyMatter platform, which utilizes artificial intelligence and machine learning to optimize delivery routes and enhance efficiency across various transportation modes, including trucks, drones, and autonomous vehicles. This expansion underscores GreyOrange's commitment to providing comprehensive supply chain solutions.

Swisslog: Background and History

Swisslog, established in 1900, is a global leader in logistics automation solutions. While heavily focused on healthcare logistics, Swisslog also provides a broad range of warehouse automation and material flow solutions. Their offerings include automated storage and retrieval systems (ASRS), conveyor systems, and advanced warehouse management software.

With a rich history of innovation, Swisslog introduced the world’s first automated hospital pharmacy system in 1969, transforming medication dispensing in healthcare facilities. Their continued advancements have led to the development of automated guided vehicles (AGVs) and pneumatic tube systems. Operating in over 20 countries, Swisslog serves diverse industries, including healthcare, retail, and e-commerce, delivering tailored automation solutions.

Comparative Analysis of GreyOrange and Swisslog

Features and Functionality

Robotics Approach

- GreyOrange: Utilizes the Butler system, which collaborates seamlessly with human workers to transport products efficiently within warehouses.

- Swisslog: Employs fully automated ASRS systems that autonomously manage product movements to and from storage locations.

Scalability and Customization

- GreyOrange: Offers modular systems that can be easily expanded or reconfigured to meet evolving business needs, providing extensive customization options.

- Swisslog: ASRS systems are highly specialized and may require significant investment and downtime for expansion or modifications, offering more standardized options.

Warehouse Management Software

- Both GreyOrange and Swisslog provide robust warehouse management software designed to optimize inventory control and streamline workflow processes.

Pricing and Affordability

Pricing for automated warehousing solutions varies based on factors such as warehouse size, product volume, and labor costs. Key considerations include:

- GreyOrange: Generally more affordable due to its hybrid approach that combines robotics with human labor.

- Swisslog: Typically involves higher costs as it offers fully automated solutions.

Maintenance and Repairs

- GreyOrange: Systems are designed for easy maintenance and repair by human technicians, resulting in lower overall costs.

- Swisslog: Fully automated systems may incur higher maintenance and repair costs due to their technological complexity.

Pros and Cons

GreyOrange

- Pros:

- Collaborative robots reduce labor costs and enhance productivity.

- Affordable implementation through a combination of robotics and human labor.

- Highly customizable to fit specific warehouse requirements, leading to increased efficiency.

- Cons:

- Requires human intervention, which may limit speed and efficiency compared to fully automated systems.

- Initial investment can be substantial, potentially posing a barrier for some businesses.

Swisslog

- Pros:

- Fully automated systems operate 24/7, offering high efficiency and accuracy in inventory management.

- Advanced safety features, such as sensors and alarms, ensure the well-being of warehouse workers.

- High level of customization allows tailored automation to specific business needs.

- Cons:

- Higher implementation costs due to the fully automated nature of the systems.

- Limited scalability, as ASRS systems may not easily adapt to changing inventory needs or warehouse space constraints.

Technology Integration with Modern Supply Chains

GreyOrange Integration

- Flexible Navigation: The Butler system is programmable to navigate complex warehouse layouts, ensuring efficient product transportation.

- Real-Time Inventory Tracking: Advanced software solutions offer up-to-date inventory visibility and optimization.

- Order Fulfillment and Sorting: Robotic solutions work alongside human workers to enhance productivity and reduce errors.

- Scalability: Systems are designed to be flexible and scalable, allowing businesses to adapt to changing market demands.

These integrations enable businesses to manage their supply chains more effectively, improving overall efficiency and responsiveness.

Swisslog Integration

- Diverse Product Handling: ASRS systems accommodate a wide range of product types and sizes, ideal for businesses with varied inventory.

- Real-Time Inventory and Workflow Optimization: Advanced software solutions provide real-time tracking and streamline warehouse operations.

- Robotic Solutions: Automated guided vehicles (AGVs) perform tasks such as picking, packing, palletizing, and transporting goods within warehouses.

- Scalability: Designed to easily expand operations as business needs evolve, catering to fast-paced market environments.

These integrations support businesses in maintaining efficient, adaptable, and responsive supply chain operations.

Real-World Case Studies

GreyOrange Applications

Fashion Industry Optimization

A global fashion brand implemented GreyOrange's Butler system to enhance warehouse operations. The system efficiently transported products, resulting in a 30% reduction in labor costs and a 20% improvement in order fulfillment times.

E-Commerce Order Management

A leading online retailer adopted GreyOrange's Sorter system to handle high order volumes. The Sorter system accurately and swiftly sorted and distributed packages, minimizing errors by 15% and accelerating delivery processes by 25%.

Healthcare Logistics Enhancement

A hospital system utilized GreyOrange's Butler system to transport medical supplies and equipment within their facilities. The system navigated complex environments efficiently, saving time and reducing error risks by 20%.

Swisslog Applications

Healthcare Pharmacy Automation

A U.S. hospital integrated Swisslog's ASRS to automate pharmacy operations. The system ensured quick and accurate storage and retrieval of medications, lowering error rates by 18% and enhancing patient care.

E-Commerce Fulfillment Streamlining

A major online retailer implemented Swisslog's automated warehouse technology to optimize order fulfillment. The system managed high order volumes effectively, reducing pick and pack times by 22% and accelerating customer delivery times by 30%.

Choosing the Right Solution for Your Business

When deciding between GreyOrange and Swisslog, businesses should evaluate the following factors:

- Warehouse Size: Larger warehouses may benefit more from Swisslog's fully automated systems, while GreyOrange offers scalable solutions suitable for various sizes.

- Product Volume: High inventory volumes may align better with Swisslog's robust automation, whereas GreyOrange provides flexibility for fluctuating volumes.

- Budget Constraints: GreyOrange's hybrid approach can be more cost-effective, especially for businesses with limited budgets.

- Customization Needs: Businesses requiring tailored solutions may prefer GreyOrange's extensive customization options.

- Future Scalability: Consider the ease of expanding and adapting the system to future business needs.

Assessing these factors in relation to your business requirements will aid in selecting the most suitable automated warehousing solution.

Future of Automated Warehouses and Material Handling Systems

As technology continues to advance, the landscape of automated warehousing and material handling systems is set to become increasingly sophisticated and efficient. Both GreyOrange and Swisslog are at the forefront of this evolution, offering solutions that deliver faster order fulfillment, enhanced inventory management, and reduced labor costs. Emerging technologies such as artificial intelligence, machine learning, and IoT integrations will further enhance the capabilities of these systems.

By selecting the right system and ensuring proper implementation, businesses can optimize their warehouse operations and secure long-term strategic advantages in their supply chains. According to a Forbes article, the global warehouse automation market is expected to grow at a CAGR of 12.61% from 2023 to 2030, highlighting the increasing importance of these technologies in modern supply chains.