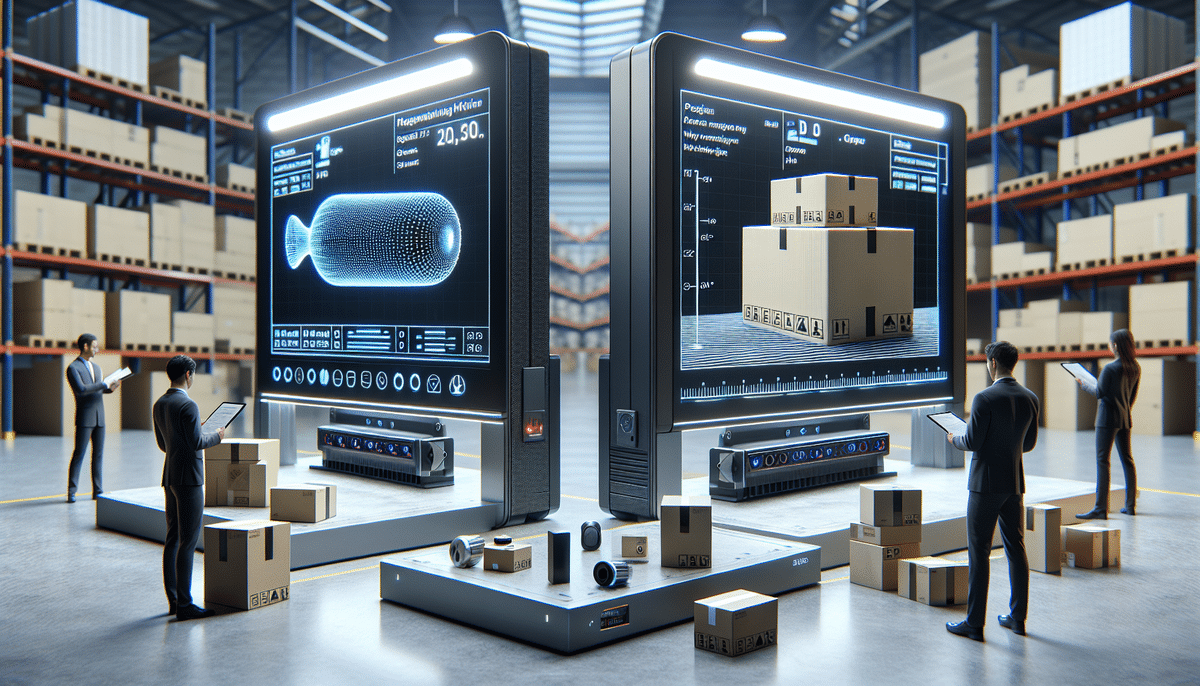

Honeywell AutoCube 8200 vs Mettler Toledo CSN840: A Comprehensive SEO-Optimized Comparison

The Honeywell AutoCube 8200 and Mettler Toledo CSN840 are industry-leading dimensioning systems widely adopted by logistics, distribution, and eCommerce companies. This comprehensive comparison examines their features, capabilities, performance, pricing, and customer reviews, facilitating an informed decision on which system best aligns with your operational needs and budget.

Overview of AutoCube 8200 and CSN840 Dimensioning Systems

The Honeywell AutoCube 8200 and Mettler Toledo CSN840 are advanced dimensioning systems engineered to measure and capture parcel dimensions and weight data accurately. This data integrates seamlessly with a logistics company’s warehouse management system (WMS), optimizing sorting, storage, and shipping processes. Warehouse management systems streamline operations by ensuring efficient handling of inventory and shipments.

The AutoCube 8200 leverages 3D imaging technology to precisely capture parcel dimensions, making it highly effective for handling irregularly shaped objects such as cylinders and spheres. In contrast, the CSN840 employs laser measurement technology, which excels in measuring larger parcels due to its extended range capabilities.

Both systems are designed for user-friendliness, requiring minimal specialized training for operation. Additionally, they provide accurate weight data capture, essential for calculating shipping costs, preventing overloading or underloading of packages, and detecting potential discrepancies that could indicate fraud.

Size and Capacity Comparison: AutoCube 8200 vs CSN840

The physical dimensions and weight capacities of these dimensioning systems are critical factors to consider when selecting the appropriate solution for your operations:

- AutoCube 8200: Compact size measuring 13 x 11.5 x 26.5 inches and weighing 20 pounds. It can handle parcels ranging from 1 x 1 x 1 inches up to 36 x 36 x 36 inches, with a weight capacity of up to 70 pounds.

- Mettler Toledo CSN840: Larger footprint at 30 x 28.5 x 50.9 inches and weighing 100 pounds. It accommodates parcels from 1 x 1 x 1 inches up to 48 x 48 x 48 inches and can weigh up to 440 pounds.

Despite their size differences, both systems deliver high measurement accuracy—AutoCube 8200 with +/- 0.2 inches and CSN840 with +/- 0.1 inches. They also support integration with various software and hardware solutions, enhancing the overall shipping and logistics workflow.

Features of Honeywell AutoCube 8200: In-Depth Analysis

The Honeywell AutoCube 8200 is equipped with features tailored to meet the dynamic needs of eCommerce, logistics, and warehousing sectors:

- Advanced 3D imaging technology for precise and rapid parcel dimensioning.

- Simplified setup and installation process.

- Compatibility with leading shipping software and warehouse management systems.

- Remote support and diagnostics capabilities.

- High-resolution image capture for detailed parcel analysis.

- User-friendly interface for ease of operation.

Additionally, the AutoCube 8200 offers extensive flexibility and customization options. Users can modify measurement units, adjust imaging resolution, and create multiple user profiles to accommodate different team members’ preferences. These features make the AutoCube 8200 a versatile tool for businesses aiming to enhance their parcel dimensioning and logistics efficiency.

Mettler Toledo CSN840: Comprehensive Feature Breakdown

The Mettler Toledo CSN840 distinguishes itself as a premium dimensioning system, ideal for high-volume warehouses and extensive logistics operations. Its key features include:

- Precise laser measurement technology for accurate dimensioning.

- Quick and straightforward setup and installation.

- Compatibility with top-tier warehouse management systems and shipping software.

- Remote support and diagnostic services.

- Integrated barcode scanning for streamlined operations.

- Robust weight capacity handling up to 440 pounds.

The CSN840 also features a highly intuitive interface, allowing users to effortlessly customize settings and parameters according to specific operational requirements. Its large display screen ensures clear visibility of measurement data, while its durable construction guarantees long-term reliability and performance, making it a valuable investment for any large-scale warehouse or logistics facility.

Pros and Cons: Honeywell AutoCube 8200 vs Mettler Toledo CSN840

When evaluating the AutoCube 8200 and CSN840, it’s essential to assess their respective advantages and disadvantages based on your business needs:

Honeywell AutoCube 8200

- Pros:

- Compact and easy to install.

- Utilizes non-invasive 3D imaging technology.

- High-resolution image capture for detailed measurements.

- Cons:

- Lower weight capacity compared to CSN840.

- Smaller parcel size range.

Mettler Toledo CSN840

- Pros:

- High weight capacity of up to 440 pounds.

- Extensive parcel size range.

- Integrated barcode scanning enhances operational efficiency.

- Cons:

- Larger footprint and higher cost compared to AutoCube 8200.

- Laser technology may not be suitable for all environments.

In terms of accuracy, both systems excel, with the AutoCube 8200 having a slight advantage due to its non-invasive 3D imaging technology, ensuring precise measurements without physical contact. Additionally, Honeywell is renowned for its exceptional customer service, offering a dedicated support team, whereas Mettler Toledo users have occasionally reported longer response times for customer assistance.

Comparative Analysis: Which System is Superior for Your Operations?

Selecting between the AutoCube 8200 and CSN840 depends on your specific operational requirements and budget constraints. Consider the following:

- If you handle smaller parcels and seek a cost-effective solution, the AutoCube 8200 is likely the better choice.

- For businesses managing larger or heavier parcels with a higher budget, the Mettler Toledo CSN840 offers superior capabilities.

The CSN840's advanced features, such as automatic dimensioning and weighing, enhance efficiency in high-traffic warehouses, while its higher accuracy rate minimizes errors, thereby improving customer satisfaction. Conversely, the AutoCube 8200 remains a viable option for those requiring fundamental dimensioning without the need for extensive features.

Installation and Setup Guide: AutoCube 8200 vs CSN840

Installing and setting up both the AutoCube 8200 and CSN840 is straightforward, with each system providing comprehensive installation guides and software compatible with computers or tablets. The general setup process involves:

- Preparing a clean, obstruction-free installation area.

- Connecting the system to a computer or tablet.

- Configuring settings to integrate with your warehouse management system or shipping software.

For optimal performance, ensure that all necessary tools, such as a power drill and screws, are available to secure the systems properly. Regular maintenance checks are recommended to sustain accuracy and efficiency, including calibration and cleaning as per the manufacturer’s guidelines.

Performance Comparison: AutoCube 8200 vs Mettler Toledo CSN840

Both systems deliver accurate and rapid dimensioning but cater to different operational scales:

- AutoCube 8200: Excels in user-friendliness and seamless integration with existing warehouse systems, making it ideal for small to medium-scale operations.

- CSN840: Offers greater weight capacity and a broader parcel size range, catering to large-scale warehouses and high-volume logistics operations.

The CSN840's extensive customization options allow businesses to tailor the system to their specific needs, while the AutoCube 8200 provides a more straightforward setup with fewer customization requirements. Your choice should align with your business’s scale, complexity, and specific performance needs.

Pricing Analysis: Comparing the Cost of AutoCube 8200 vs Mettler Toledo CSN840

The pricing of the AutoCube 8200 and CSN840 varies based on vendors, regions, and currency fluctuations. Generally, the AutoCube 8200 is more affordable than the Mettler Toledo CSN840. However, it’s crucial to evaluate the overall value and benefits each system provides beyond the initial cost.

- AutoCube 8200: Offers cost savings through its ability to accurately measure irregularly shaped objects and integration with warehouse management software for streamlined operations.

- CSN840: While more expensive, it provides advanced features like automatic dimensioning and weighing, higher weight capacity, and enhanced accuracy, justifying the investment for larger operations.

Consider long-term maintenance and support costs when making your decision to ensure that you’re getting the best value for your investment.

Maintenance and Support: Evaluating Value for Money

Both the AutoCube 8200 and CSN840 come with warranty and customer support services. However, the quality and responsiveness of support can vary:

- Honeywell AutoCube 8200: Renowned for exceptional customer service with a dedicated support team, ensuring minimal downtime and reliable assistance.

- Mettler Toledo CSN840: Provides robust customer support, though some users have reported longer wait times for assistance compared to Honeywell.

Selecting a vendor that offers responsive and reliable customer support is essential to maintain system performance and promptly address any issues.

Customer Reviews: Insights on AutoCube 8200 vs CSN840

Customer feedback for both systems is predominantly positive, highlighting their accuracy, ease of use, and compatibility with various software systems. Key points include:

- AutoCube 8200: Praised for its compact design, non-invasive 3D imaging technology, and high-resolution image capture.

- CSN840: Appreciated for its high weight capacity, extensive parcel size range, and integrated barcode scanning.

However, some users have noted the AutoCube 8200's limited weight capacity and parcel size range as drawbacks, while others have expressed concerns about the CSN840's larger size and reliance on laser technology in certain environments.

Conclusion: Making the Right Choice Between AutoCube 8200 and CSN840

Selecting between the AutoCube 8200 and CSN840 depends on your specific operational needs and budget:

- Choose AutoCube 8200: If you require an affordable, compact system capable of handling smaller parcels with high accuracy and seamless integration into existing systems.

- Choose CSN840: If your operations involve larger or heavier parcels, and you need advanced features such as automatic dimensioning and weighing to enhance efficiency and accuracy.

Ultimately, consider all factors, including system features, performance, pricing, maintenance and support, and customer reviews, to make an informed purchasing decision that best fits your business requirements.